D32mm Elongated Concrete Hole Drill Bits with Crown Segment

October 3, 2024

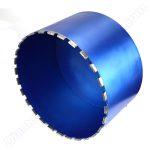

406mm Diamond Core Drill Bit for Concrete

October 3, 202476mm Assembled Wet Core Drill Bits for Concrete

- Application

- Drilling concrete, and reinforced concrete

- Core Bit Size

- D76*L350mm

- Connection

- 1-1/4

- Segment Type

- Roof

- Welding Type

- Laser welding

- Net Weight

- Will update soon

- MOQ

- 3 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

Table of Contents

Product Features

- Versatility: Available in various sizes and configurations, they can be customized to meet specific drilling needs across different materials.

- Ease of Assembly and Replacement: The modular design allows for quick assembly and easy replacement of worn-out parts, avoiding the need to replace the entire bit.

- Cost-Effective: By replacing only damaged components, users can significantly reduce costs compared to buying a whole new drill bit.

Description

Our Assembled Wet Core Drill Bits for Concrete are designed for precision drilling in concrete, reinforced concrete, brick, and asphalt. Featuring a modular construction with replaceable drill heads, tubes, and couplings, these wet core drill bits for concrete offer flexibility and cost efficiency. Available in a range of diameters from 10mm to 1000mm, they are ideal for heavy-duty construction applications. The wet drilling design ensures effective cooling and debris removal, extending the life of the bit and enhancing performance. Compatible with electric, hydraulic, and standard drilling machines, these bits are perfect for professionals seeking reliable, high-performance tools. OEM and ODM services are also available.

Advantages

Assembled wet core drill bits for concrete bring a range of advantages to the table:

- Versatility: These bits come in a variety of sizes and configurations, allowing them to be tailored to different drilling needs. Whether you’re cutting through concrete, asphalt, or brick, the flexibility of assembled core drills ensures they adapt to the task at hand with ease.

- Ease of Assembly and Replacement: Thanks to their modular design, these drill bits are incredibly easy to assemble. When wear and tear take their toll, you can simply swap out the damaged parts without the hassle of replacing the entire bit—saving both time and effort.

- Cost-Effective: By replacing only the worn components, you get more bang for your buck. There’s no need to invest in a whole new drill bit when you can keep performance high by just renewing the parts that matter. This makes them a smart, budget-friendly solution for demanding drilling jobs.

Welding Types

We provide two welding options for our diamond core bits for concrete: high-frequency welding and laser welding. Laser welding delivers enhanced strength, making it the preferred choice for core bits used on reinforced concrete, where segments face significant stress when cutting through rebar. High-frequency welding is commonly used for core bits designed to cut materials like standard concrete, lightly reinforced concrete, stone, brick, and other construction materials.

For more details on the differences between high-frequency welding and laser welding, please refer to our article: 2 Diamond Tools Welding Methods: High-Frequency VS Laser.

3 specifications

When purchasing concrete diamond core bits, it is essential to confirm three key specifications: diameter, length, and connection type. Once these are determined, we can manufacture a tool precisely tailored to your needs.

Diameter

Core bits have two diameters due to the thickness of the barrel: the outside and inside diameters. However, “diameter” typically refers to the outside diameter.

Length

A core drill bit consists of three main parts: the segments, barrel body, and connection. While each part has its own length, “length” generally refers to the barrel body alone, excluding the connection and segments.

Connection

The connection type is another critical specification, as it determines how the core bit attaches to your drilling machine. Threaded connections are the most common, including 1 1/4″ UNC, G 1/2″, M14, and 5/8″-11.

Packaging – wet core drill bits for concrete

Packaging of short diamond core bits

Packaging of long diamond core bits

We use specialized packaging methods for our short and long diamond core drill bits to ensure they are well-protected during transit.

For short core bits, we pack them in a durable green hard box with foam cushioning, offering maximum impact protection.

For longer core bits, we wrap the body in a protective net to prevent scratches, then place it securely in a white box. This customized packaging guarantees both types of drill bits arrive safely and in pristine condition, ready for use.

| Diameters | 76mm |

|---|---|

| Length | 350mm |

| Connection | 1 1/4 |

| Segment Types | Roof |

| Welding Types | Laser |

Related products

-

Turbo Type Diamond Core Bit Segments for Concrete

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Turbo

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments

-

D177mm Concrete Diamond Core Bit with Roof Segments

- Application

- Drilling concrete, and other hard materials

- Core Bit Size

- D177*L250mm

- Connection

- 1-1/4-7

- Segment Type

- Roof

- Welding Type

- High-frequency welding

- Net Weight

- 4.7kg

- MOQ

- 3 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

-

Turbo-roof Core Bit Diamond Segments for Concrete

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Turbo + Roof

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments

Reviews

There are no reviews yet.