Table of Contents

Concrete core drill bits are specially designed for drilling into concrete and reinforced concrete. Constructed with premium diamonds, these bits handle the toughness of hard, abrasive surfaces, making them ideal for creating precise holes for plumbing, electrical work, and structural modifications. They efficiently cut through both standard concrete and reinforced concrete, which includes embedded steel rebar. Available in various diameters and lengths, concrete core drill bits offer versatility for a range of construction and renovation tasks.

7 things you may need to know

When buying concrete core drill bits, there are 7 things you may need to know to ensure you make the best choice for your specific needs.

1. Core drill bit types

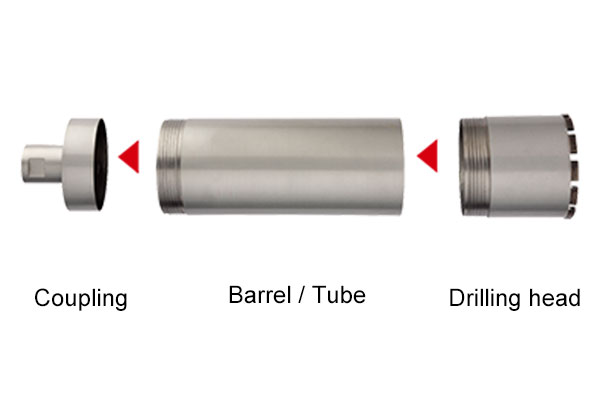

Completed core drill bit

Assembled core drill bit

There are mainly two different types of core drill bits: the assembled type and the complete type.

For used core drill bits, you have two options: retip the core bit segments with welding equipment, or replace the entire drilling head. While retipping is more complex, it provides more reliable performance for drilling concrete or reinforced concrete. The assembled core drill bits are generally preferred for drilling materials like stone or brick.

2. Segment types

We provide different types of segments for concrete core drill bits. Crown segments are used for core drill bits with small diameters under 50mm. Bar-type segments cover a much larger range of diameters, from 32mm to 500mm. We offer 8 different types of bar-type segments to choose from, and you can also customize segments for other types or larger core drill bits.

3. Concrete types & segment grades

Concrete can vary in rebar density (reinforced concrete). To address different needs, we classify concrete into three levels: high-density rebar, medium-density rebar, and low-density rebar (new or green concrete). Each level has specific diamond segment formulas designed to match its requirements. Grade A is for concrete with high-density rebar, Grade B is for concrete with medium-density rebar, and Grade C is for concrete with low-density rebar.

4. Connections

The connection method is crucial for securely attaching concrete core drill bits to core drill machines. This connection ensures that the drill bits remain firmly in place during operation, allowing for efficient and accurate drilling. Below are four common connection types.

1 1/4 UNC

This connection type features a Unified National Coarse (UNC) thread with a diameter of 1 1/4 inches. It is a standard choice for many core drill machines, providing a robust and stable attachment.

G 1/2″

This connection uses a 1/2-inch British Standard Pipe (BSP) thread. The “G” designation indicates a parallel thread, which is commonly used in European and international core drilling systems. It offers a reliable and precise fit.

M14

This connection includes a 14mm metric thread, suitable for various core drill machines. The metric threading ensures compatibility with equipment that uses standard metric connections.

5/8″-11

This type features a 5/8-inch diameter with 11 threads per inch. It is a popular choice in North American core drill machines, providing a secure and stable connection for effective drilling.

5. Core drill bit size

For core drill bit size, the two key specifications are diameter and length. The diameter determines the size of the hole the bit will create, affecting both the size of core samples and the drill bit’s performance. The length of the core drill bit, specifically the length of the barrel, defines the depth of the core that can be drilled, impacting the maximum drilling depth and the bit’s maneuverability. Both measurements are crucial for ensuring the drill bit is suitable for specific applications and achieves optimal performance.

Core drill bit diameter

For concrete core drill bits, there are two measurements due to the barrel’s thickness: the outer diameter and the inner diameter. Generally speaking, when we refer to the diameter of a drill bit, we usually mean the outer diameter.

Core drill bit length

The core drill bit has three different parts in the vertical direction: the connection, the barrel cylinder, and the segments. The length of our concrete core drill bit refers to the length of the barrel body only, excluding the segments and connections.

6. Welding methods

Like other diamond tools, concrete core drill bits use two different welding methods: high-frequency welding and laser welding. Laser welding offers stronger bonding and is typically used for drilling concrete with high or medium-density rebar or for dry drilling applications. In contrast, high-frequency welding is generally used for drilling new or green concrete with low-density rebar and is recommended for wet drilling.

For more information about high-frequency welding and laser welding, please refer to this article: 2 Diamond Tools Welding Methods: High-Frequency VS Laser.

7. Wet/dry use

Wet drilling

Dry drilling

Different drilling projects have varying requirements, with some necessitating wet use and others dry use. To meet these needs, we have developed distinct diamond formulas tailored for each application.

For dry use, the segments are designed to be more heat resistant to withstand higher temperatures. Generally, we recommend wet drilling because it helps cool the drill bit, reduces dust, and enhances the overall efficiency and lifespan of the tool. Wet drilling also provides a cleaner cut and minimizes wear and tear on both the equipment and the material being drilled.

Concrete core drill bits

Concrete core drill bits are highly customized to meet specific needs and applications, so we do not offer standard models. Instead, we tailor each drill bit to the unique requirements of the project, ensuring optimal performance and efficiency. To give you an idea of our offerings and capabilities, we have included some pictures of the concrete core drill bits we have previously customized. These images showcase various designs and configurations to illustrate the level of customization we can achieve for different drilling applications.

| Table of Laser Welded Concrete Core Drill Bits | |||

|---|---|---|---|

| Outer Diameter | Thickness of Barrel | Segment No. | Roof Segment Size |

| mm | mm | pieces | mm |

| 25 | 2 | 3 | 12*3.5*10 |

| 28 | 2 | 3 | 12*3.5*10 |

| 30 | 2 | 4 | 12*3.5*10 |

| 32 | 2 | 3 | 18*3.5*10 |

| 35 | 2 | 3 | 18*3.5*10 |

| 38 | 2 | 3 | 18*3.5*10 |

| 40 | 2 | 4 | 18*3.5*10 |

| 45 | 2 | 4 | 18*3.5*10 |

| 51 | 2 | 4 | 24*3.5*10 |

| 55 | 2 | 4 | 24*3.5*10 |

| 60 | 2 | 5 | 24*3.5*10 |

| 63 | 2 | 5 | 24*3.5*10 |

| 70 | 2 | 6 | 24*3.5*10 |

| 75 | 2 | 6 | 24*3.5*10 |

| 82 | 2 | 7 | 24*3.5*10 |

| 92 | 2 | 8 | 24*3.5*10 |

| 102 | 2 | 9 | 24*3.5*10 |

| 108 | 2 | 9 | 24*4.0*10 |

| 112 | 2 | 9 | 24*4.0*10 |

| 122 | 2 | 10 | 24*4.0*10 |

| 127 | 2 | 11 | 24*4.0*10 |

| 132 | 2 | 11 | 24*4.0*10 |

| 142 | 2.5 | 12 | 24*4.0*10 |

| 152 | 2.5 | 12 | 24*4.0*10 |

| 162 | 2.5 | 12 | 24*4.5*10 |

| 172 | 2.5 | 12 | 24*4.5*10 |

| 182 | 2.5 | 13 | 24*4.5*10 |

| 202 | 2.5 | 15 | 24*4.5*10 |

| 225 | 2.5 | 16 | 24*4.5*10 |

| 252 | 2.5 | 16 | 24*4.5*10 |

| 302 | 3 | 17 | 24*5.0*10 |

| 352 | 3 | 20 | 24*5.0*10 |

| 402 | 3 | 23 | 24*5.0*10 |

| 452 | 3 | 26 | 24*5.0*10 |

| 502 | 3 | 29 | 24*5.0*10 |

| 552 | 3 | 32 | 24*5.0*10 |

| 602 | 3 | 35 | 24*5.0*10 |

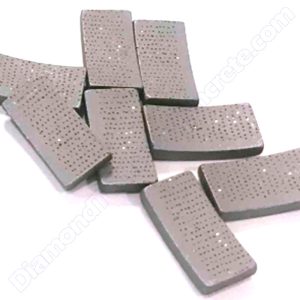

Accessories

For concrete core drill bits, we offer core bit segments specifically designed for retipping. Retipping involves replacing the worn segments of the core bit with new ones, which can significantly extend the life of the tool. If you have the capability to retip the barrel yourself or through a local service, it can be a cost-effective solution compared to purchasing entirely new drill bits. This approach not only helps in reducing overall costs but also minimizes waste, making it an environmentally friendly option. By utilizing our core bit segments for retipping, you can maintain optimal performance and prolong the usability of your core drill bits.

OEM service

We offer additional services for painting and laser engraving.

For end-users such as contractors, most do not require customized painting colors or logo engraving. In such cases, we proceed with standard painting and engraving procedures. However, most resellers seek to enhance brand visibility and recognition by customizing painting colors and engraving logos on tools.

Painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for Xpert Diamond Tools

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Laser engraving

Our standard engraving process involves laser engraving several key details on concrete core drill bits, including the logo, size, application, connection type, etc.

Payment methods and terms

Regarding the payment process for concrete core drill bits, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete core drill bits, we maintain a diverse inventory of different carbide rollers and blank plates compatible with common floor grinding machines like HTC, Lavina, Husqvarna, Blastrac, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Packaging

For concrete core drill bits, our packaging method is designed to ensure maximum protection during transportation and storage. We begin by wrapping each core drill bit with a protective net to guard against scratches and minor impacts. The wrapped drill bit is then placed into a sturdy hard box. To further cushion and secure the drill bit, the box is filled with foam, which absorbs shocks and prevents movement within the box. This multi-layered packaging approach helps to maintain the integrity of the drill bits and ensures they arrive at their destination in optimal condition.

Wrapped by net

White box and foam

Minimum packaging

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods from the Air Port yourself | Door-to-door Door-to-CY(Container Yard) Door-to-CFS(Container Freight Station |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.