800mm Diamond Saw Blade for Concrete Cutting

September 14, 2024

16 Inch Asphalt Diamond Blade with 4 Drop Segments

September 16, 2024

14 Inch Asphalt Cutting Blade with Drop Segments

- Application

- Cutting asphalt for road and pavement repairs, creating expansion joints, etc.

- Features

- With 3 drop segments

- Welding Method

- Laser welding

- Diameter

- 14″(350mm)

- Segment Type

- Normal segments

- Segment Size

- 40*12mm

- Segment No.

- 21pcs(3 drop segments)

- Net Weight

- will update soon

- MOQ

- 5 pieces

- Lead Time

- 10-20 days

Buying Guide for Asphalt Cutting Blade

Table of Contents

Product Features

- Durability: Laser-welded 14-inch blade with 3 drop segments for enhanced durability.

- Precision Cutting: Specially designed for fast, precise cutting of asphalt surfaces like roads.

- Material Removal: Drop segments are recessed to remove abrasive materials efficiently.

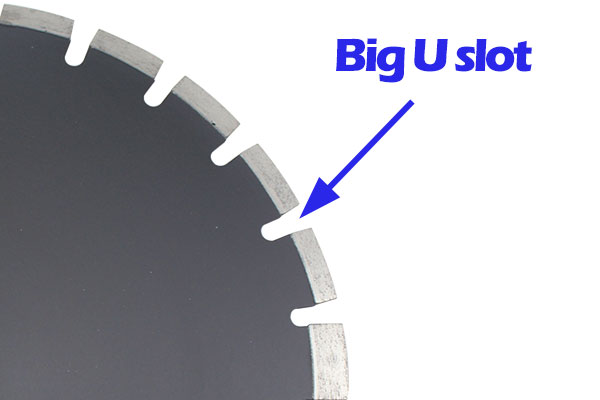

- Chip Removal: Blank core with large U slots improves chip removal and ensures a smoother, cleaner cut.

- Wet Cutting: Ideal for wet cutting, minimizing dust and overheating.

Description

This 14 inch asphalt cutting blade is laser welded with 3 drop segments, specially designed for fast and precise cutting of asphalt, such as roads and other surfaces. The drop segments are recessed to remove abrasive materials from the cutting area. Suitable for wet use.

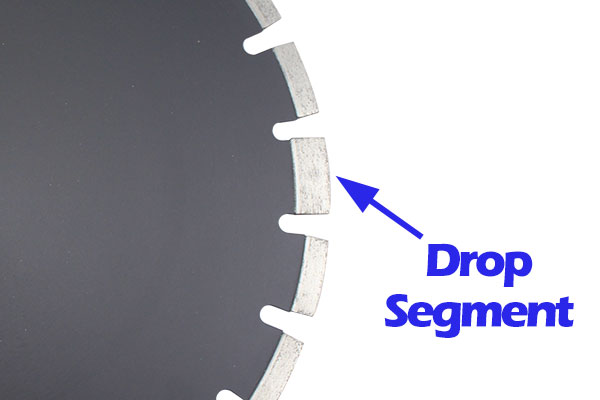

Drop segments

Big U slots

Compared with concrete, asphalt is more flexible and tends to be softer than concrete. It consists of bitumen (a sticky, black substance) mixed with aggregates. This material can be quite tacky and sticky, especially in warmer temperatures, which can make the cutting process messier.

The bitumen in asphalt can cause the cuttings to adhere to the cutting equipment and the surrounding area, making clean-up more challenging. So we use the blank core with big U slots, to improve the clear-up of cutting chips, ensuring a smoother and cleaner cutting process.

Drop segments

The 14 inch asphalt cutting blade is often equipped with multiple drop segments and utilizes laser welding technology.

Drop segments are a crucial design element that boosts the blade’s performance, safety, and longevity, making it ideal for cutting through tough asphalt. As asphalt becomes sticky and heats up during cutting, the drop segments help minimize friction and improve cooling, resulting in better overall performance and extended blade life.

Laser welding

Laser welding is utilized in this 14 inch asphalt cutting blades to form a strong, durable, and precise bond between the diamond segments and the steel core. This process enhances the blade’s performance, safety, and lifespan, allowing it to endure the high stress and heat generated during asphalt cutting.

Lifespan

The lifespan of an asphalt cutting blade is usually measured by its cutting depth and length. For instance, our 350mm asphalt blade with a 10mm segment height can cut over 1,000 meters of grooves at a 10cm depth. We offer three quality levels with different diamond formulas to meet the needs of customers in various regions. These diamond formulas can be fine-tuned based on customer feedback after testing our asphalt cutting blades.

Packaging – 14 inch asphalt cutting blade

Packaging of Medium Size Diamond Saw Blade

The common diameter range of asphalt cutting blades typically spans from 300mm (12 inches) to 600mm (24 inches). Smaller blades, such as 300mm to 350mm (12-14 inches), are often used for handheld saws, while larger blades, like 500mm to 600mm (20-24 inches), are commonly used with walk-behind saws for cutting asphalt on roads and other large surfaces.

Due to the blade’s diameter, we typically pack the asphalt cutting blade in a white box, which is the second packaging method we use for concrete cutting blades. First, the diamond blades are shrink-wrapped in transparent plastic, and then the asphalt cutting blade is placed in a white box for added protection.

| Diameters | 400mm |

|---|---|

| Segment Types | Drop |

| Welding Types | Laser |

| Silent/Non-Silent | Non-Silent |

| Wet/Dry Cutting | Wet |

Related products

-

Turbo Segmented 350mm Diamond Cutting Blade for Concrete

- Application

- for cutting concrete and reinforced concrete

- Features

- multi holes core

- Welding Method

- Laser welding

- Diameter

- 350mm

- Segment Type

- turbo segments

- Segment Size

- 40*3.2*10mm

- Segment No.

- 24pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

14 Inch Arix Diamond Blade for Concrete Cutting

- Application

- for cutting concrete and reinforced concrete

- Welding Method

- Laser welding

- Diameter

- 350mm

- Segment Type

- Arix segments

- Segment Size

- 40*3.6*12mm

- Segment No.

- 24pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

Vacuum Brazed Diamond Wire for Concrete (Reinforced) Cutting

- Application

- Cutting concrete and reinforced concrete.

- Features

- Vauum brazed beads

- Lenth

- 3.4 meter

- Fix Type

- Rubber + Spring

- Bead Size

- 11.0mm

- Net Weight

- 0.35kg/meter

- MOQ

- 10 meters

- Lead Time

- 1-2 weeks

Buying Guide for Concrete Wire Saw

-

14 Inch Concrete Cutting Blade with Silent Core

- Application

- for cutting concrete and reinforced concrete

- Welding Method

- Laser welding

- Diameter

- 350mm

- Segment Type

- normal segments

- Segment Size

- 40*3.2*12mm

- Segment No.

- 24pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade