270mm HTC Adapter Plate for Husqvarna Redi-lock Grinding Shoes

August 20, 2024

600mm Arix Laser Wall Saw Blades with Inclined Segments

August 21, 2024

Segment Magnet Tool for Retipping Barrels

- Application

- For retipping core bit segments on blank barrels

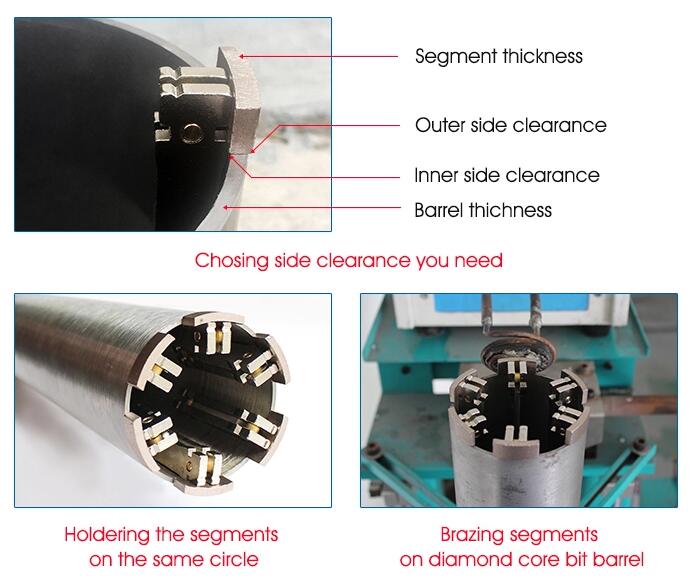

- Available Side Clearance

- 4 different side clearance

- Net Weight

- will update soon

- MOQ

- 10 meters

- Lead Time

- 1-2 weeks

Table of Contents

Product Features

- Expert-Level Brazing Made Easy: Simplifies the process so anyone can achieve professional results.

- Increased Efficiency: Speeds up the soldering process for diamond core bits.

- Precision Positioning: Ensures accurate placement of segments for improved drilling accuracy.

- Versatile Design: Features four adjustable side clearances to fit various diameters.

- Eco-Friendly and Cost-Effective: Reusable magnets save money and reduce waste.

Description

This segment magnet tool is used for retipping core bit segments on both new and used barrels, aiding operators in evenly positioning and fixing the segments. It helps position the diamond core bit segments, typically 4mm thick, onto a 2mm thick barrel during brazing. This ensures accurate welding, maintains balance, and enhances the stability of the core drill bits.

Made from strong N35EH neodymium magnets, it offers both high magnetism and heat resistance. This tool ensures precise positioning of drilling segments, and the inner side clearance can be adjusted by placing the magnet in different positions (a, b, c, d).

Welding guide

Rules

Usually, when welding the segments on the blank barrel, the rule is:

- Inner side clearance=( Segment Width- Steel core width)x0.4

- Outer side clearance=( Segment Width- Steel core width)x0.4

Size table

Please check the segment size and corresponding steel core width for reference:

| Diameter(mm) | Segment No. | Segment Size | Segment Thickness | Steel Core(Barrel) Thickness |

|---|---|---|---|---|

| D25 | 3 | 15*3.5*9mm | 3.5mm | 2.0mm |

| D32 | 4 | 15*3.5*9mm | 3.5mm | 2.0mm |

| D38 | 5 | 20*3.5*9mm | 3.5mm | 2.0mm |

| D44 | 5 | 20*3.5*9mm | 3.5mm | 2.0mm |

| D52 | 5 | 24*3.5*10mm | 3.5mm | 2.0mm |

| D58 | 5 | 24*3.5*10mm | 3.5mm | 2.0mm |

| D63 | 6 | 24*3.5*10mm | 3.5mm | 2.0mm |

| D76 | 7 | 24*3.5*10mm | 3.5mm | 2.0mm |

| D89 | 8 | 24*3.5*10mm | 3.5mm | 2.0mm |

| D102 | 9 | 24*4.0*10mm | 4.0mm | 2.0mm |

| D108 | 10 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D114 | 10 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D127 | 11 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D140 | 11 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D152 | 12 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D167 | 12 | 24*4.0*10mm | 4.0mm | 2.5mm |

| D180 | 14 | 24*4.5*10mm | 4.5mm | 3.0mm |

| D200 | 14 | 24*4.5*10mm | 4.5mm | 3.0mm |

| D230 | 15 | 24*4.5*10mm | 4.5mm | 3.0mm |

| D250 | 16 | 24*4.5*10mm | 4.5mm | 3.5mm |

Technical Support

1. Is the brazing difficult? What do I need to start retipping?

If you’re new to brazing, don’t worry—it’s a skill you’ll pick up quickly. We’ll provide all the necessary information and equipment recommendations. With a bit of practice, you’ll get the hang of it in no time.

2. What do I need to get started?

When you order retipping equipment from us, let us know the segment length you typically use. In Europe, the most common length is 24 mm (1” in the USA).

For brazing, we recommend using acetylene/oxygen gas with a torch head that produces a concentrated flame. You can purchase these supplies from your local supplier. A good starting quantity is 12 magnets, which will allow you to braze core bits up to Ø 150 mm (6”) in one batch. We also offer silver and flux specially designed for these tasks.

3. How many segments should I use?

We provide a chart with our equipment that shows the recommended number of segments for different diameters. You can adjust this based on your preferences. If you’re drilling very hard materials, need faster drilling, or have a less powerful machine, you might opt for fewer segments.

4. What segment width should I choose?

The segment width should account for the steel thickness, with a minimum clearance of 0.5 mm (0.02”) on the smallest bits. Generally, you’ll need a bit more clearance on the outside than on the inside. For more powerful machines or when drilling more abrasive materials, a larger clearance is preferable.

5. What is the lifespan of the magnets?

The magnets are durable and can be used thousands of times.

6. Can I buy just the steel barrels to make my own diamond core bits?

Yes, you can purchase only the steel barrels and use them to manufacture your own diamond core bits.

Related products

-

270mm HTC Adapter Plate for Redi-lock Grinding Shoes

- Application

- Adapt HTC floor grinders to work with redi-lock concrete grinding diamonds like Husqvarna, Scanmaskin

- Diameter

- 270mm

- Seats Quantity

- 6 redi-lcok seats

- Net Weight

- will update soon

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

-

Flexiable RBP-B Rubber Backing Pads for Angle Grinder Polisher

- Application

- Rubber Backing Pad for Angle Grinder Sander Polisher

- Diameter

- 3″, 4″, 5″

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

-

270mm HTC Adapter Plate for Husqvarna Redi-lock Grinding Shoes

- Application

- Adapt HTC floor grinders to work with Husqvarna redi-lock concrete grinding diamonds like Husqvarna, Scanmaskin

- Diameter

- 270mm

- Seats Quantity

- 6 redi-lcok seats

- Net Weight

- will update soon

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

-

Bush Hammer Cover for Protection and Dust Collection

- Application

- Protection and dust collection for 150mm angle grinder bush hammer plate

- Suitable Grinders

- Makita 9237C, Bosch GPO12 CE

- Net Weight

- 1.3kg

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Bush Hammers