Table of Contents

We’ve crafted a purchasing guide to assist our customers in acquiring the metal bond concrete grinding diamonds they desire. These tools are non-standard and can be tailored to your specific needs. If you’re inclined to delve into details, feel free to peruse this guide at your leisure. However, if time is of the essence or you’re not particularly interested, simply reach out to our sales team. We’ll gladly recommend the most suitable metal bond concrete grinding segments for your grinding requirements.

PS: With coarse diamonds (such as 6#, 10#, 16#), some types of concrete grinding segments can also effectively remove thin floor coatings, such as those featuring zigzag segments.

5 things you may need to know

Initially, you must decide on the specific shapes, height, and quantities of the grinding segments you require, followed by selecting the appropriate diamond grits and bond types.

1. Segment shapes

There are 3 most commonly used segment shapes, including segment bar, segment button, arrow segment.

Below are some features that some of our customers consider, provided for your reference only:

- Segment Button: The segment button, characterized by its round shape, is recommended for use with fine diamonds (such as 100#, 120#). Customers find that it tends to leave fewer scratches.

- Segment Bar: Also known as the rectangle segment, the segment bar is favored by some customers to work with medium diamonds (e.g., 40#, 60#). It is commonly employed for medium grinding tasks, resulting in medium-level scratches.

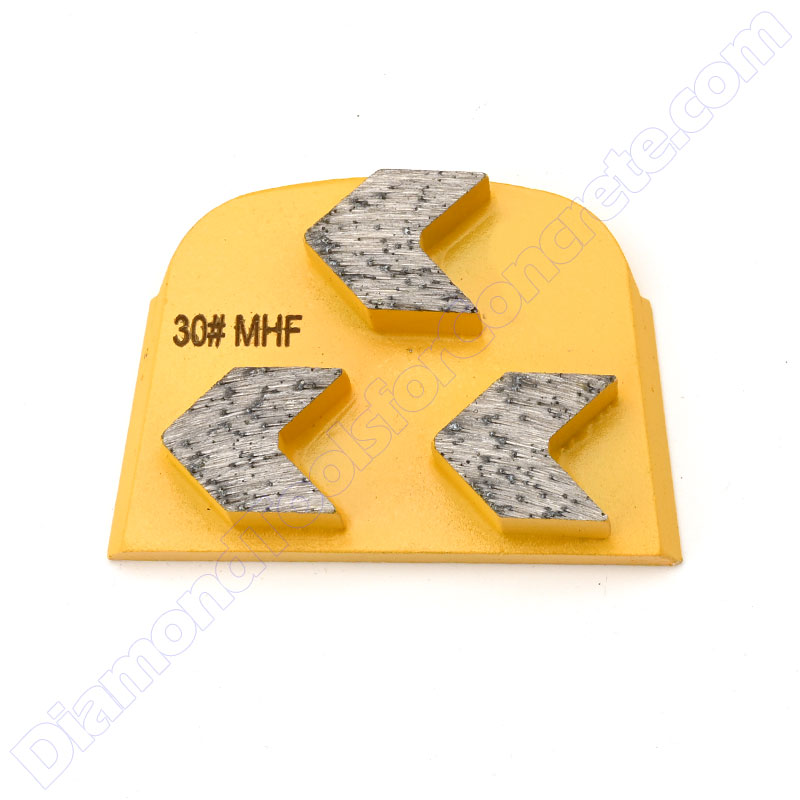

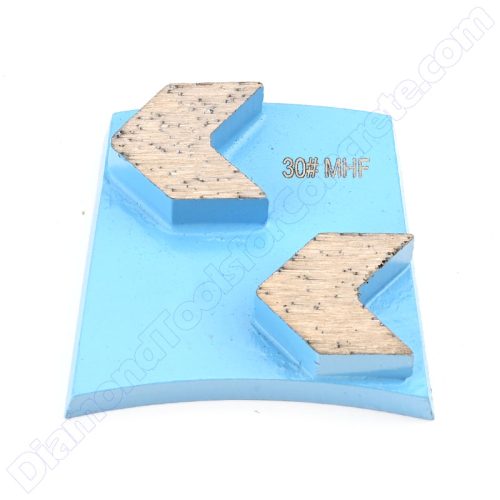

- Arrow Segment: Arrow segments are generally perceived as more aggressive and are preferred for use with coarse diamonds (e.g., 6#, 16#) to achieve aggressive grinding. They tend to leave behind more-pronounced scratches.

Bar, button, and arrow segments are 3 essential segments, but we also have many other different types. We can also build the segment type according to your demons.

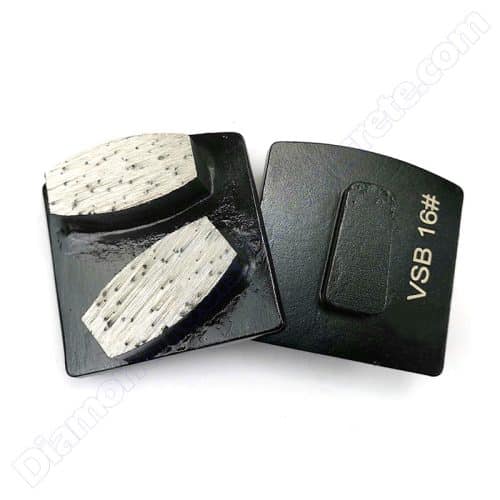

Segment bar

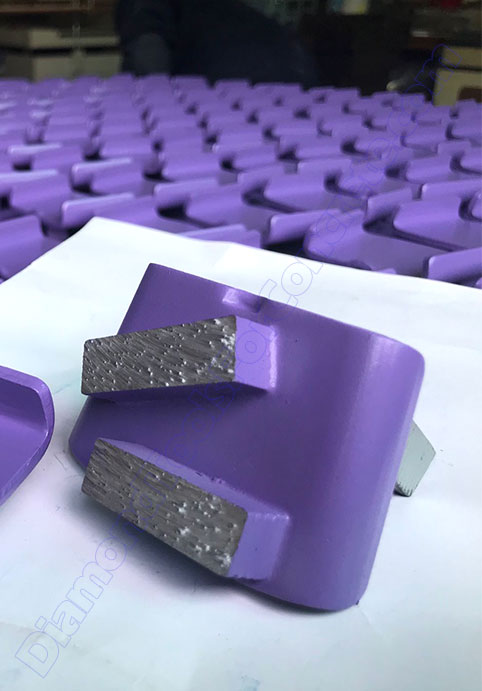

Segment button

Arrow segment

2. Segment height

For a specific concrete grinding segment, we can offer different segment heights. The segment height not only relates to the price and the lifespan of the tools but also affects the shipping costs. If you are a concrete grinding contractor, a higher segment height can help you save on shipping costs. How does it do this? Please refer to our article: “3 Benefits of Higher Concrete Grinding Segments.

For different shapes of segments, common segment heights include 10mm, 12mm, 13mm, and 15mm. Please contact our sales team for the specific segment height you require. Whether you are a reseller or contractor, we can customize the concrete grinding diamond to meet your needs.

3. Segment quantity

The segment quantities are related to the grinding job, The more aggressive the grinding you want, the fewer segments there should be. This is because at the head pressure, more pressure is distributed over fewer segments:

- 2 or 3 segment tools are designed for heavier machines. However, we recommend using single-segment tools for the first step even with heavier machines (for faster opening of the concrete).

- Single segmented tools are designed for lighter machines, or where aggressive stock removal is required.

4. Diamond grits

Diamond particle size is commonly measured in terms of diamond grit. At Xpert Diamond Tools, we employ diamond particles ranging from 6# to 220# for concrete grinding purposes: 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#.

The numerical value corresponds to the size of the diamond particle, with smaller numbers indicating larger particles and more aggressive action on concrete surfaces.

- For tasks requiring coarse grinding or coating removal, opt for 6#, 10#, 16#, 20# and 25# diamond particles.

- For medium grinding, select from 36#, 60#, and 80# diamond particles.

- For fine grinding applications, utilize 100#, 120#, 180#, and 220# diamond particles

5. Bond types

Different concrete have different hardness. When buying metal bond concrete floor grinding diamonds, it’s very important to select the right bond to fit your specific hardness of concrete or terrazzo floor.

The relationship between the hardness of the concrete and the bond is inverse. For instance, if the concrete is extremely hard, then an extremely soft bond is needed. Please check the details in the flowing chart:

Concrete hardness and corresponding bond types

| Concrete Hardness | Extremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| MOH’S | 7-9 | 5-7 | 4-5 | 3-4 | 2-3 | 1-2 |

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Bond Type | Extremely Soft Bond | Very Soft Bond | Soft Bond | Medium Bond | Hard Bond | Very Hard Bond |

| Bond Codes | XSB | VSB | SB | MB | HB | VHB |

| Floor Codes | XHF | VHF | HF | MF | SF | VSF |

| Color Represented |

Metal bond concrete grinding diamonds

As specialists in manufacturing concrete grinding diamonds, Xpert Diamond Tools offers a comprehensive range of premium metal bond tools for concrete grinding machines. Our products are available with leading brands such as HTC, Lavina, Husqvarna, Blastrac, ASL, Klindex, EDCO, Scanmaskin, Werkmaster, Airtec, Cassani, ESD, KutRite, Newgrind, PHX, Syntec, and more.

HTC/Husqvarna(EZ system) concrete grinding diamonds

HTC quick-change diamond tooling is specially designed for use on HTC or Husqvarna (EZ system) floor grinders. Our HTC shoes are made based on the original HTC steel base to ensure our tools fit HTC machines perfectly.

Lavina concrete grinding diamonds

Lavina concrete grinding diamonds are very popular for concrete grinding. There are two versions: Old and New. The New version is recommended as it is designed for X machines, but is also compatible with Lavina S and Pro models. Three threaded holes are optional, as you requested.

Husqvarna/Diteq concrete grinding diamonds

With corresponding Redi-Lock backs, these concrete grinding diamonds are designed for Husqvarna and Diteq grinders. They are lighter compared to other diamond tooling, which can save on shipping costs. The Redi-Lock quick-change system makes it easy for operators to change these tools.

Scanmaskin concrete grinding diamonds

Similar to Husqvarna concrete grinding diamonds, these Scanmaskin diamond tools also have a Redi-Lock back for a quick change, but their Redi-Lock is different in shape and size. We provide various shapes of the steel base for Scanmaskin shoes, including square, trapezoid, hexagon, and heart shapes.

2 arrows

1 button

2 octagons

1 octagon

2 half-hearts

Klindex/Hyper concrete grinding diamonds

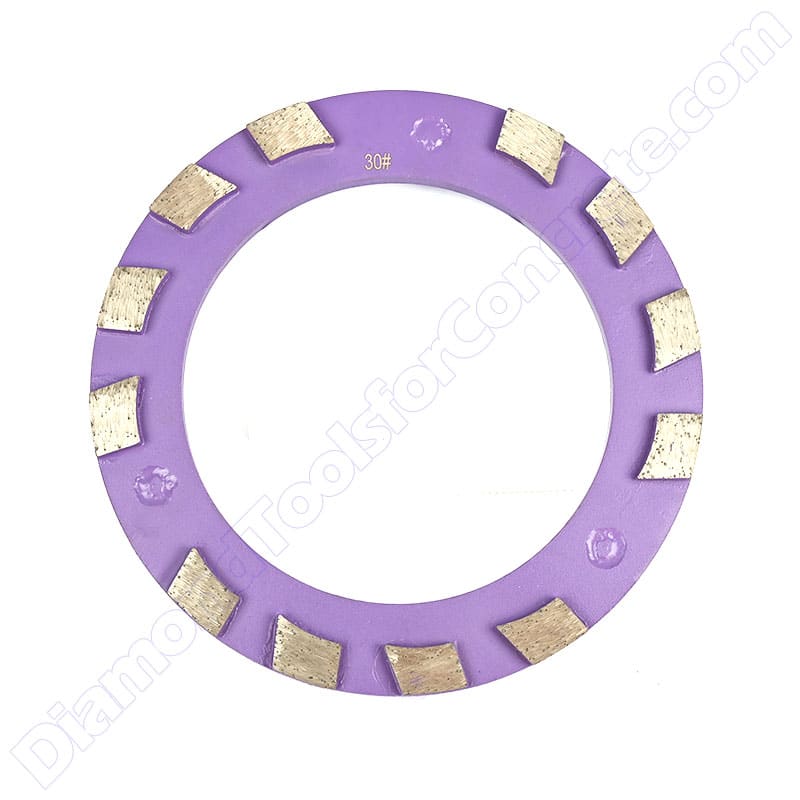

Klindex and Hyper concrete grinding diamonds share the same diamond tooling. For different grinder models, the tools can be 100mm or 140mm round diamond discs, or 200mm and 240mm diamond rings. The Klindex diamond tooling features a 3-pin connection system designed for secure and reliable attachment.

Square Redi-lock Klindex concrete grinding plates

2 bars

100mm Klindex concrete grinding plates

5 curved bars

5 bars

7 cubes(for marble floor)

140mm Klindex concrete grinding plates

5 curved bars

200mm Klindex concrete grinding rings

6 curved bars

9 bars

12 cubes(for marble floor)

240mm Klindex concrete grinding rings

6 curved bars

12 bars

12 bars

12 bars

16 cubes(for marble floor)

EDCO concrete grinding diamonds

We primarily supply 250mm concrete grinding wheels specifically designed for EDCO grinders. These high-quality grinding wheels are engineered to deliver high productivity and stable performance, making them ideal for various heavy-duty concrete surface preparation tasks.

250mm

20 bars

250mm

20 bars

250mm

20 bars

250mm

20 arrows

4 bars

4 bars

Trapezoid concrete grinding diamonds

There are a variety of floor grinders that use trapezoid concrete grinding diamonds. The connection can be threaded holes or unthreaded holes with magnets. The type with 3 threaded holes is universal and compatible with various floor grinders. We provide different trapezoid shoes for other grinders like ASL, ESD, KutRite, Blastrac, Airtec, etc.

2 bars

2 buttons

3 buttons

2 arrows

3 arrows

2 top grooves

ASL

2 Z-shapes

ASL

2 arrows

ESD

2 arrows

KutRite

2 buttons

Blastrac

1 button

Airtec

Plug concrete grinding diamonds

Our Plug Concrete Grinding Diamonds are compatible with any machine that accepts 2″ taper fit plugs, including Satellites, Masterfinish, Terrco, STI, and Blastrac Grinders. These diamond plugs are heavy in weight and designed for heavy grinding work.

1 big button

3 arrows

5 arrows

8 spirals

Other concrete grinding diamonds

Below are some concrete grinding diamonds for other brands of floor grinding machines, including HT, Sase, Newgrind, Werkmaster, Syntec, PHX, Cassani, and more. If you don’t find the appropriate grinding diamonds you want, please contact us to customize the tools. We offer full support for OEM/ODM orders.

10 sectors

HT & Sase

1 arc-side

Newgrind & Rhino

2 buttons

Newgrind & Rhino

1 square

Werkmaster

2 bars

Syntec

2 arrows

Syntec

2 bars

PHX

2 buttons

PHX

5 bars

Cassani

5 bars

Cassani

5 bars

Cassani

Accessories

To make the concrete grinding diamonds compatible with different brands of floor grinders, we supply several adapters to ensure a perfect fit. 2 types of adapters are provided, one is for transfer metal/PCD shoes and the other is for using velcro diamond polishing pads.

Additionally, we offer the Mohs Hardness Test Kit, which helps you test the hardness of the concrete and select the optimal bond type for your concrete grinding diamonds and concrete cup grinding wheels.

Adapters for metal/PCD shoes

Below are some adapters we’ve made to make metal/PCD shoes compatible with various floor grinders. With our extensive experience in OEM/ODM orders, we can also customize adapters to meet your specific needs.

HTC to Trapezoid

HTC to Husqvarna

HTC to Husqvarna

EDCO to Trapezoid

Klindex to Trapezoid

100mm Plastic Velcro Adapter

140mm Metal Velcro Adapter

Mohs hardness test kit

The Mohs Hardness Test Kit is a simple tool used to determine the hardness of materials, such as concrete, by scratching the surface with different minerals. Each mineral in the kit corresponds to a specific hardness level on the Mohs scale, ranging from 1 (softest) to 10 (hardest). By identifying the hardest mineral that can scratch the concrete, you can determine its hardness, which helps in selecting the appropriate tools and bond types for grinding and polishing.

OEM service

We offer additional services for painting and laser engraving.

For end-users such as contractors, most do not require customized painting colors or logo engraving. In such cases, we proceed with standard painting and engraving procedures. However, most resellers seek to enhance brand visibility and recognition by customizing painting colors and engraving logos on tools.

Painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for Xpert Diamond Tools

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Laser engraving

Our standard engraving process includes laser engraving three parts on the tools: the logo, grit, and bond.

Regarding the bond, you can choose between bond codes or floor codes. Bond codes are directly related to the tools, while floor codes are related to the hardness of the floor. Both methods are utilized by our customers. If not specified, we typically engrave the bond codes.

Packaging

In general, you needn’t worry about packaging arrangements as we handle it entirely on your behalf. When it comes to packaging, there are two primary considerations: box material and quantity per box.

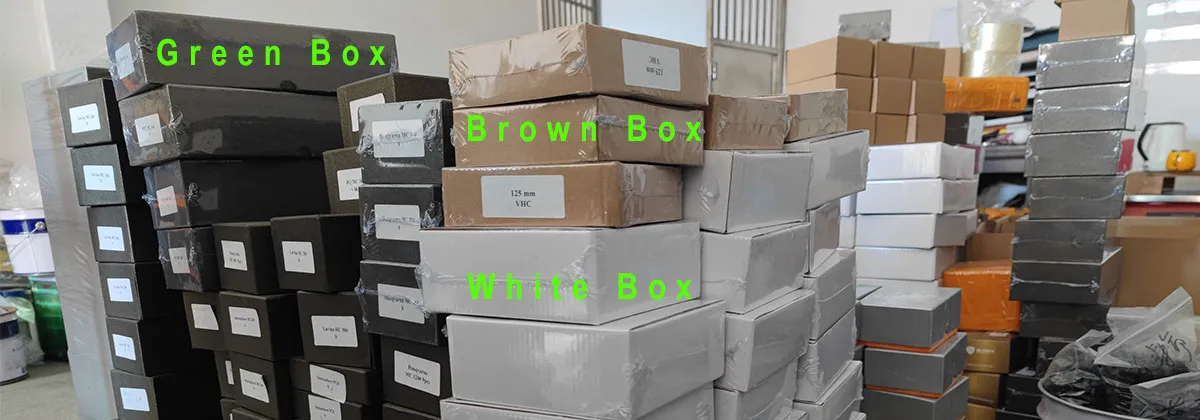

Box materials

We offer three types of packing materials: the green hard box, the brown hard box and the white box. The green hard box is sturdier than the brown box, yet some customers prefer the brown option due to concerns about material wastage and environmental impact.

Quantity per box

Our metal bond concrete floor grinding diamonds are packaged in hard boxes containing 1pc, 3pcs, 6pcs, or 9pcs.

- The 1pc packaging is typically employed for large round-shaped concrete grinding discs, such as the 240mm Klindex grinding rings and 250mm EDCO floor grinding wheels.

- The 3pcs packaging is suitable for round grinding pucks.

- The 6pcs and 9pcs packaging options are versatile and can accommodate various types of concrete grinding diamonds, including Lavina, Husqvarna, HTC, Blastrac, and other types.

1 pc per box

One pc per box is used to pack diamond cup wheels or big concrete grinding wheels such as 250mm EDCO concrete floor grinding wheels.

3 pcs per box

3 pcs per box is used to pack concrete grinding pucks with 76mm or 83mm diameter. It may has a redi-lock, like Husqvarna diamond grinding pucks.

6 pcs per box

6 pcs per box is generally used to pack trapezoid and other normal floor grinding shoes, like ASL, HTC, Lavina, etc. This box is used the most and we recommend it.

9 pcs per box-A

This 9 pcs per box uses 9X1 layout and can be used to pack the normal floor grinding diamond segments like trapezoid, ASL, HTC, Lavina, Blastrac, Scanmaskin, etc.

9 pcs per box-B

This 9 pcs per box uses 3X3 layout and can be used to pack the normal floor grinding diamond segments like trapezoid, ASL, HTC, Lavina, Blastrac, Scanmaskin, etc.

Payment methods and terms

Regarding the payment process for concrete grinding diamonds, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete grinding diamond tools, we maintain a diverse inventory of different blank plates compatible with common floor grinding machines like HTC, Lavina, Husqvarna, Blastrac, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods yourself or Door-to-door service |

Pick up the goods yourself or Door-to-door service |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.