Product Category

Diamond polishing pads are usually resin-bonded and round-shaped. They are Velcro-backed and can be easily mounted on floor grinding machines for polishing stone floors or concrete floors. While the polishing pads for concrete floors are much thicker than the pads for stone. The diamond grits of the resin-bonded polishing pads are: 50#, 100#, 200#, 400#, 800#, 1500#, 3000#, and buff.

In addition to resin bond, there are also some other bonds for transitioning between grinding and polishing, including copper bond, ceramic bond, and hybrid bond. These bond types are usually used for transition, and the price is much higher than resin bond. Some customers have the habit of using these transition bonds before using resin bond for polishing.

Not all diamond polishing pads are round. There are also many other shapes of diamond polishing pads developed to be used on different floor grinding machines. Xpert Diamond Tools can provide all kinds of premium diamond polishing pads, with different patterns on them.

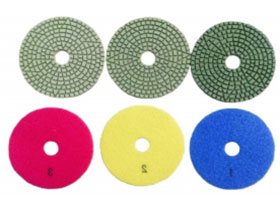

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4"), 125mm(5")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

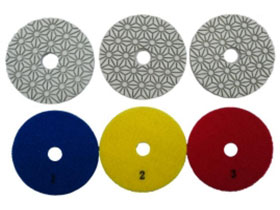

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Pattern

- Grid

- Optional Diameter

- 80mm(3"), 100mm(4"), 125mm(5"), 150mm(6"), 180mm(7"), 230mm(9")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Pattern

- Classic

- Optional Grits

- 50#, 100#, 200#, 400#, 800#, 1500#, 3000# and Buff

- Net Weight

- 0.2kg

- MOQ

- 6 pieces

- Lead Time

- 1-2 weeks

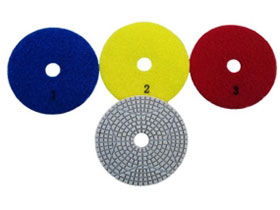

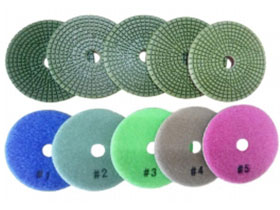

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3, step4, step5

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

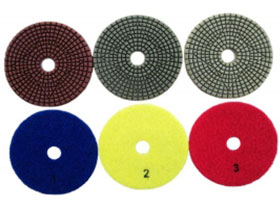

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Diameters

- 100mm(4")

- Optional Grits

- step1, step2, step3, step4, step5

- MOQ

- 6 sets

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surface

- Suitable Grinders

- Polishers like FEIN MultiMaster, Dremel Multi-Max, Rockwell SoniCrafter

- Optional Grits

- 30#, 60#, 120#, 200#, 400#, 600#

- MOQ

- 6 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surfaces

- Optional Grits

- 60#,120#, 200#

- MOQ

- 6 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surface

- Suitable Grinders

- Floor grinding machines

- Optional Size

- 7″, 9″, 11″, 17″

- Optional Grits

- 50#, 100#, 200#, 400#, 800#, 1500#, 3000#

- MOQ

- 3 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surface

- Suitable Grinders

- Floor grinding machines

- Optional Size

- 11″

- Optional Grits

- 50#, 100#, 200#, 400#, 800#, 1500#, 3000#

- MOQ

- 3 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surface

- Suitable Grinders

- Floor grinding machines

- Optional Size

- 7″, 9″, 11″

- Optional Grits

- 50#, 100#, 200#, 400#, 800#, 1500#, 3000#

- MOQ

- 3 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete and stone surface

- Suitable Grinders

- Floor grinding machines

- Optional Size

- 11″

- Optional Grits

- 50#, 100#, 200#, 400#, 800#, 1500#, 3000#

- MOQ

- 3 pieces per grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 80mm(3")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 80mm(3")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 100mm(4")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 125mm(5")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 180mm(7")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Grinders with velcro connection

- Optional Diameter

- 80mm(3")

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- HTC Grinders and other with adapters

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks

- Application

- Polishing concrete & terrazzo floor

- Suitable Grinders

- Werkmaster Grinders and other with adapters

- Optional Grits

- 30#, 50#, 100#, 200#, 400#

- MOQ

- 6 pieces each grit

- Lead Time

- 1-2 weeks