Table of Contents

Diamond cup wheels have a cup-like shape with the diamond segments located on the outer edge of the cup. They are typically used for aggressive material removal and fast surface preparation, such as grinding concrete, stone (granite, marble, etc.), and masonry. They are usually attached to angle grinders or floor grinders with a specific mounting system, such as threaded or arbor attachments.

Concrete grinding cup wheels are diamond cup wheels specifically designed for grinding concrete, with corresponding diamond grits and bond types. When buying concrete grinding cup wheels, there are 5 things you may need to know to help you make the right decision.

5 things you may need to know

By considering these five factors—diameter, connections, production techniques, diamond grits, and bond types—you can make an informed decision when buying concrete grinding cup wheels, ensuring optimal performance and efficiency for your specific grinding tasks.

1. Diameters

The diameter of the concrete grinding cup wheels determines the area it can cover and its suitability for different types of grinding machines. Common diameters range from 100mm(4″), 115mm(4.5″), 125mm(5″), 180mm(7″), to 230mm(9″), with larger diameters generally providing faster material removal over larger surface areas.

2. Connections

5/8″-11

M14

The attachment method or connection type is critical to ensure compatibility with your grinding machine. Common connection types include threaded(M14, M24, 5/8″-11), arbor hole(22.23mm), flange connection, and other specialized mounting systems. Ensure the cup wheel’s connection matches your grinder’s specifications to avoid any fitting issues.

3. Production techniques

The manufacturing process of the concrete grinding cup wheels significantly affects its performance and durability. The three main production techniques are hot pressing, high-frequency welding, and vacuum-brazed. The diamond density in high-frequency welded cup wheels is much higher than the hot-pressed type, so it is much more durable and provides a longer lifespan. while hot-pressed wheels offer a cost-effective solution for various grinding applications. For now, Xpert Diamond Tools mainly provides high-frequency welded and vacuum-brazed diamond cup wheels.

4. Diamond grits

Diamond particle size is commonly measured in terms of diamond grit. The grit size of the diamond segments determines the level of aggressiveness and the finish quality. Lower grit numbers (such as 16 or 30) indicate coarser, more aggressive grinding suitable for fast material removal. Higher grit numbers (such as 80 or 120) provide a finer finish, ideal for smoothing and polishing surfaces.

At Xpert Diamond Tools, we employ diamond particles ranging from 6# to 220# for concrete grinding purposes: 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, and 220#.

- For tasks requiring coarse grinding or coating removal, opt for 6#, 10#, 16#, 20#, and 25# diamond particles.

- For medium grinding, select from 36#, 60#, and 80# diamond particles.

- For fine grinding applications, utilize 100#, 120#, 180#, and 220# diamond particles.

5. Bond types

The bond type refers to the material that holds the diamond segments together. Different bonds are designed for varying hardness levels of concrete. Soft bonds are suitable for hard concrete surfaces as they wear away faster, exposing new diamonds for effective grinding. Conversely, hard bonds are ideal for soft concrete surfaces to ensure the diamond segments last longer.

Different concrete have different hardness. When buying metal bond concrete floor grinding diamonds, it’s very important to select the right bond to fit your specific hardness of concrete or terrazzo floor.

The relationship between the hardness of the concrete and the bond is inverse. For instance, if the concrete is extremely hard, then an extremely soft bond is needed. Please check the details in the flowing chart:

Concrete hardness and corresponding bond types

| Concrete Hardness | Extremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| MOH’S | 7-9 | 5-7 | 4-5 | 3-4 | 2-3 | 1-2 |

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Bond Type | Extremely Soft Bond | Very Soft Bond | Soft Bond | Medium Bond | Hard Bond | Very Hard Bond |

| Bond Codes | XSB | VSB | SB | MB | HB | VHB |

| Floor Codes | XHF | VHF | HF | MF | SF | VSF |

| Color Represented |

Metal bond concrete grinding cup wheels

We designed different types of concrete grinding cup wheels for different angle grinders, like Hilti, Tylorit, and other general grinding machines. They are available in various diameters, segments, and connections.

Each type of cup wheel is engineered to handle specific grinding tasks, ensuring optimal performance and longevity. Our range includes cup wheels for heavy-duty grinding, ideal for removing thick coatings and leveling uneven surfaces, as well as wheels designed for precision work, such as smoothing and finishing concrete floors.

By providing a comprehensive selection of diameters, segment configurations, and connection types, we ensure that you can find the perfect concrete grinding cup wheel for your specific equipment and application needs.

100mm(4″) concrete grinding cup wheels

100mm is the smallest size of concrete grinding cup wheels, making it ideal for precision work and accessing tight or hard-to-reach areas. Despite its compact size, it offers aggressive grinding power with fast material removal.

125mm(5″) concrete grinding cup wheels

We offer a variety of 125mm (5″) concrete grinding cup wheels for grinding concrete and terrazzo floors, including turbo type, spiral type, Z shape, T shape, single row, double row, zigzag, and vacuum brazed types, among others.

150mm(6″) concrete grinding cup wheels

150mm (6″) concrete grinding cup wheels offer a versatile balance between maneuverability and surface coverage, making them suitable for a wide range of grinding tasks. This size provides enhanced stability and faster material removal, making it effective for larger areas and heavy-duty applications.

180mm(7″) concrete grinding cup wheels

180mm concrete grinding cup wheels are used for larger surface areas where more aggressive grinding is required. They are ideal for both concrete and terrazzo floors, providing efficient material removal and a smooth finish. These wheels are perfect for heavy-duty grinding applications, ensuring quick and effective results on expansive surfaces. Our 180mm cup wheels come in various types, each designed to meet specific grinding needs, from rapid removal of material to precise finishing touches.

230mm(9″) concrete grinding cup wheels

These 230mm concrete grinding cup wheels are the largest we manufacture. It provides a significantly larger grinding area and much higher grinding efficiency. Ideal for heavy-duty applications, it offers an extended lifespan, making it a reliable choice for demanding grinding tasks.

OEM service

We offer additional services for painting and laser engraving.

For end-users such as contractors, most do not require customized painting colors or logo engraving. In such cases, we proceed with standard painting and engraving procedures. However, most resellers seek to enhance brand visibility and recognition by customizing painting colors and engraving logos on tools.

Painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for Xpert Diamond Tools

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Laser engraving

For concrete grinding cup wheels, you can generally engrave much more information compared to concrete grinding diamonds. This includes details such as the logo, diamond grits, bond types, rotation direction, connection, RPM, safety icons, and more.

Regarding the bond, you can choose between bond codes or floor codes. Bond codes are directly related to the tools, while floor codes are related to the hardness of the floor. Both methods are utilized by our customers. If not specified, we typically engrave the bond codes.

Packaging

In general, you needn’t worry about packaging arrangements as we handle it entirely on your behalf. When it comes to packaging, there are two primary considerations: box material and quantity per box.

Box materials

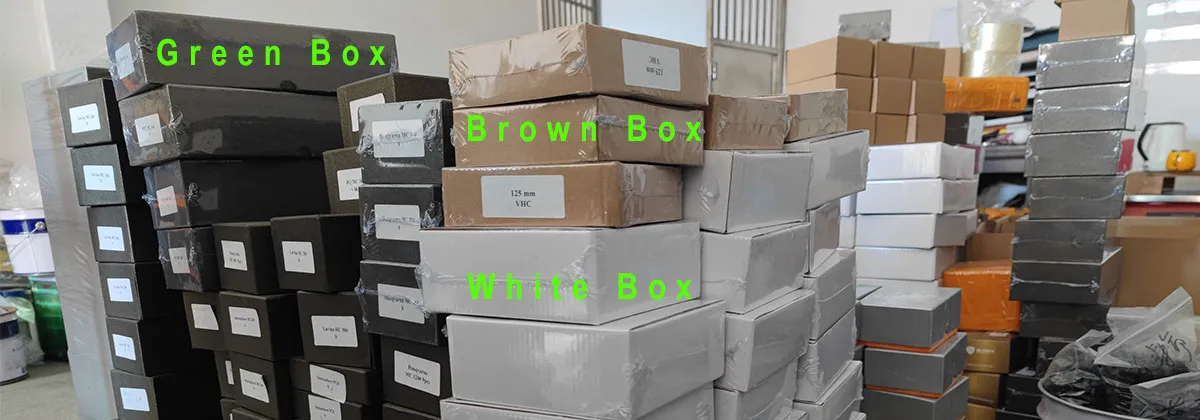

We offer three types of packing materials: the green hard box, the brown hard box and the white box. The green hard box is sturdier than the brown box, yet some customers prefer the brown option due to concerns about material wastage and environmental impact.

Quantity per box

Unlike the floor grinding shoes, which are packaged with multiple pieces per box, our concrete grinding cup wheels are individually packed, with one piece per box. Each box is square-shaped and comes in various sizes to accommodate the different diameters of the cup wheels. This specialized packaging ensures that each diamond cup wheel is protected during transport and storage, maintaining its quality and performance.

Payment methods and terms

Regarding the payment process for concrete grinding cup wheels, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete grinding cup wheels, we maintain a diverse inventory of different blank cups designed for different angle grinders, like Hilti, Tyrolit, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods yourself or Door-to-door service |

Pick up the goods yourself or Door-to-door service |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.

Cautions

How to use

- Follow the instructions provided in the machine handbook carefully.

- Never fit a diamond dish/cup wheel that is too loose or too tight on the flange.

- Tighten only with the tool supplied with the machine.

- Ensure the wheel is properly gripped to prevent slippage, but do not tighten with excessive force. Never use a hammer.

- Keep flanges and screw threads clean and free of burrs and rust.

- Replace distorted or damaged flanges before fitting the wheel.

For your safety

We recommend using the following personal protective equipment:

- Eye protection

- Ear protection (ear sets)

- Hand protection (gloves)

- Lung protection (dust mask or respirator)

Important note

Never remove the protective machine guard and make sure it is properly adjusted to deflect debris away from you. Ensure that no other person is at risk, especially near the machine while it is in operation.