Table of Contents

Concrete cutting blades are extensively employed across various construction fields due to their versatility and effectiveness. They can be fitted onto different types of equipment, including handheld saws for small or detailed cuts, walk-behind cutters for larger, more extensive work, and wall saws for vertical cutting on walls or ceilings. Their applications are diverse. Each application may require specific types of blades and techniques to ensure efficiency and precision.

Road Construction

For creating expansion joints, removing damaged sections, or cutting through concrete roads for repair or modification.

Building Renovations

To cut through floors, walls, or ceilings for new openings or to remove old structures.

Utility Installation

For cutting through concrete to install plumbing, electrical conduits, or HVAC systems.

Demolition

To precisely cut concrete elements during demolition projects, enabling controlled removal of sections.

Infrastructure Maintenance

For repairs and upgrades on bridges, highways, and other concrete infrastructure.

7 things you may need to know

When buying concrete cutting blades, there are seven key factors that will help you make the right choice.

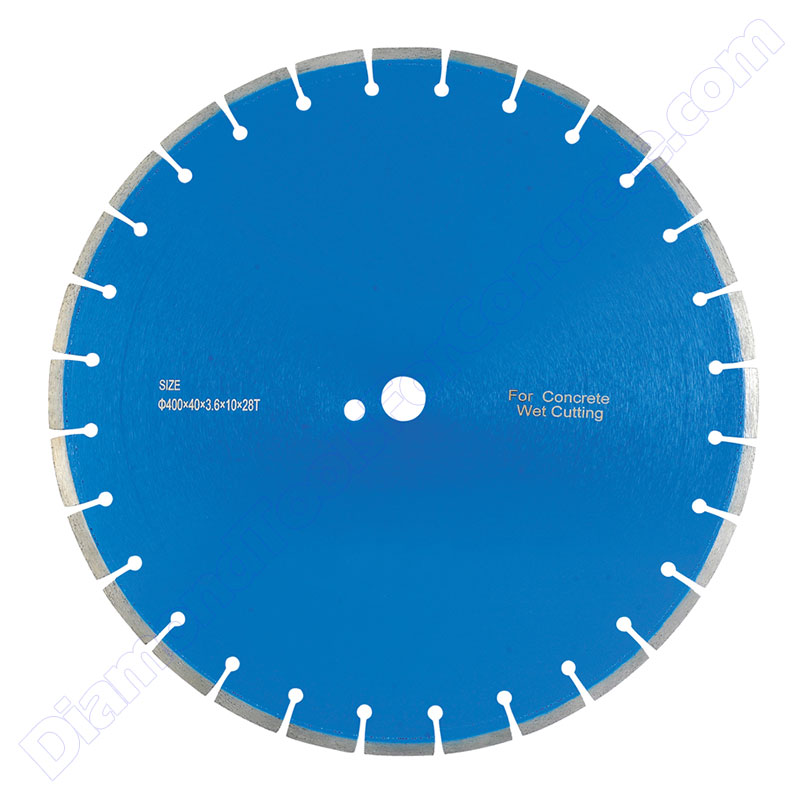

1. Diameter

The diameter is a fundamental specification for concrete cutting blades, as it directly impacts both the compatibility with your cutting machine and the ability to meet your cutting depth requirements. A blade’s diameter determines how deep it can cut into concrete, making it essential to choose the right size for your specific needs. If the diameter is too small, the blade may not achieve the desired depth; if it’s too large, it may not fit your cutting equipment.

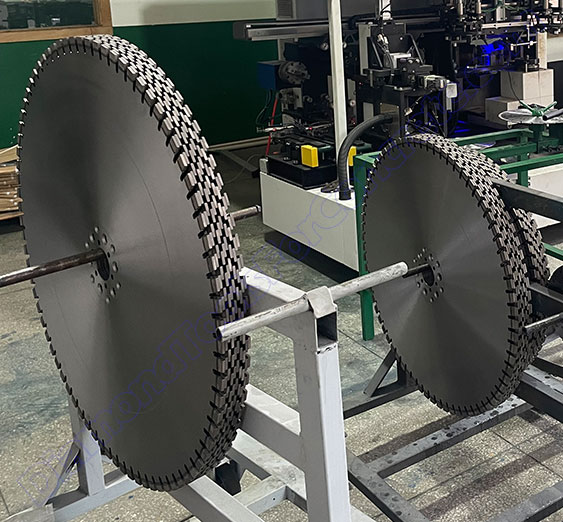

Xpert Diamond Tools offers an extensive range of diameters to accommodate various cutting tasks and machinery. Our range includes blades with diameters up to 1200mm for laser-welded concrete cutting, allowing for deep and efficient cuts in large-scale projects.

Additionally, the diameter of a diamond blade may vary slightly from the indicated measurement. This discrepancy arises because the diameter measurement includes both the segments and the core (blank blade). Since there are several commonly used segment heights, such as 10mm, 12mm, and 15mm, it’s normal to see minor differences when measuring the actual diameter.

2. Connection(Arbor)

The connection of the blade, also known as the arbor, is a critical feature for installing diamond blades onto cutting equipment. The arbor ensures that the blade is securely mounted and properly aligned with the cutting machine. Common arbor sizes for concrete cutting blades include 22.23mm, 25.4mm, among others.

It’s important to choose an arbor size that matches your equipment’s specifications to ensure compatibility and optimal performance. Additionally, you have the option to customize the arbor to meet the unique requirements of your machine, ensuring a precise fit and efficient operation.

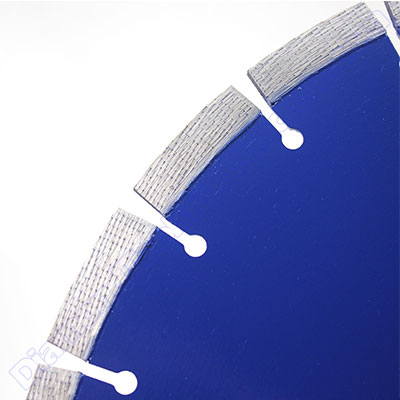

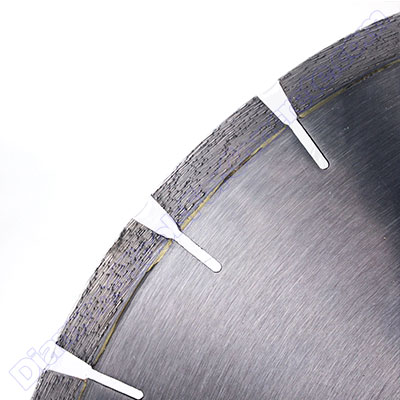

3. Segment types and height

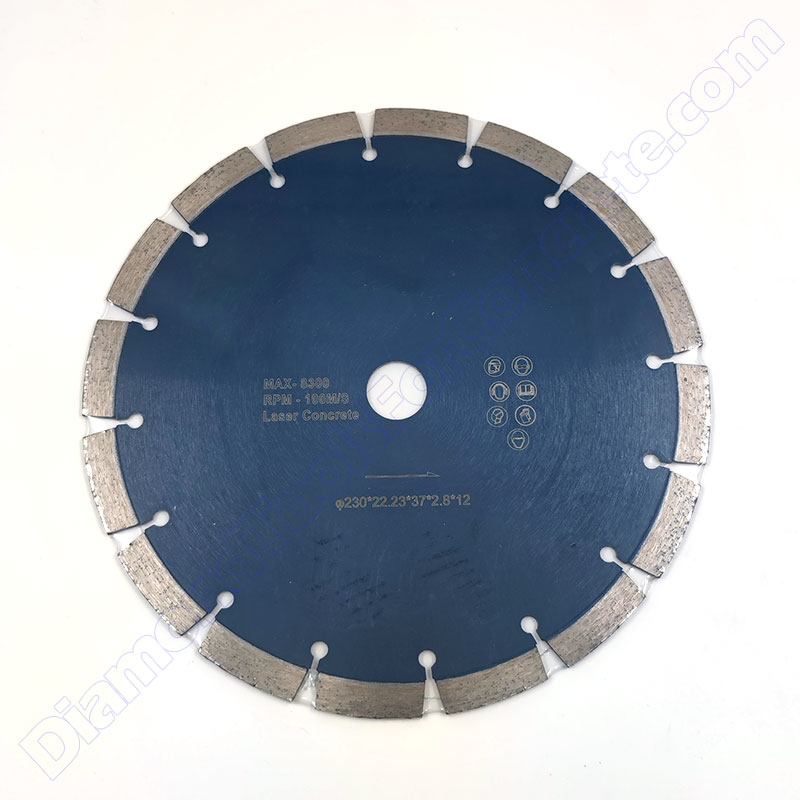

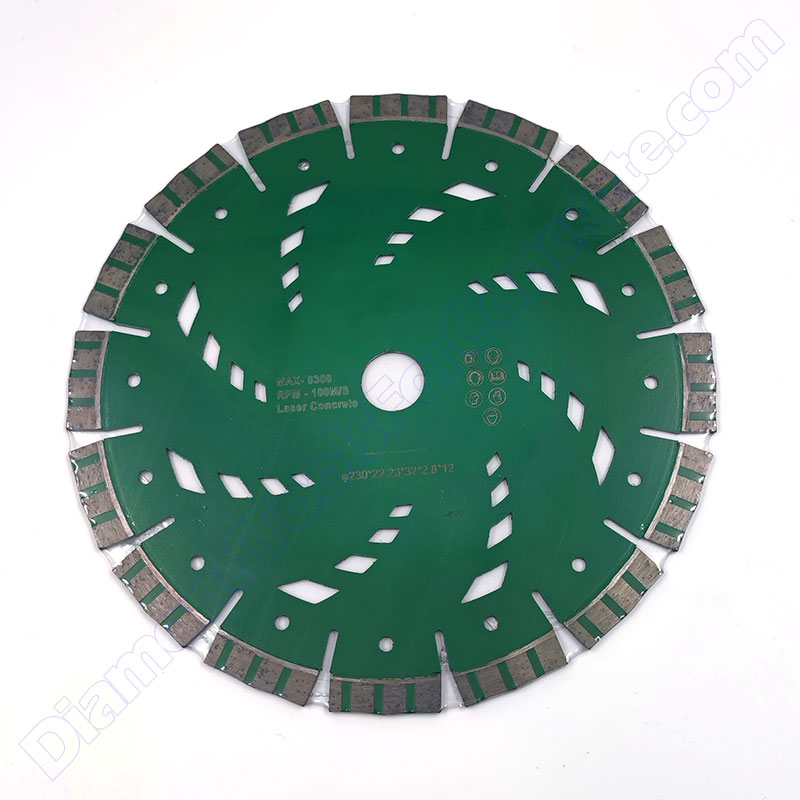

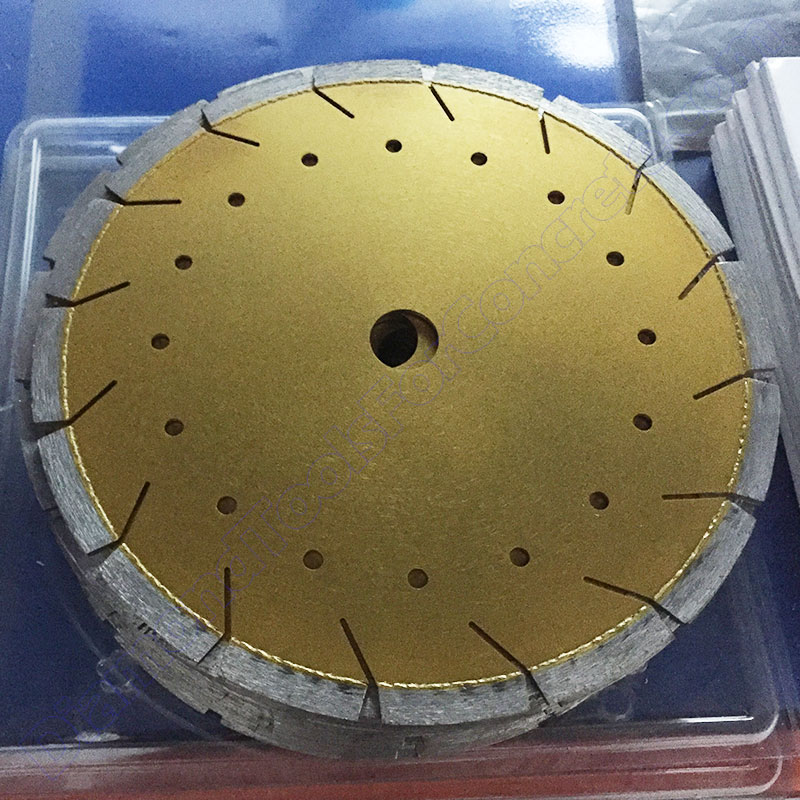

To meet diverse customer needs, we offer three main types of segments on our blades for cutting concrete and reinforced concrete: Normal Type, Turbo Type, and Arix Type. Each segment type provides distinct cutting performance, tailored to different cutting requirements. The common segment heights of concrete cutting blades are 10mm, 12mm, and 15mm.

Arix segments

Arix segments offer exceptionally fast cutting speeds, enabling you to complete tasks ahead of schedule and reduce labor costs.

Normal segments

Normal segments are the most cost-effective of the three types. They provide a standard cutting speed and offer a good balance between performance and lifespan.

Turbo segments

Turbo segments offer a medium cutting speed and are highly effective at removing cutting chips, providing improved performance compared to standard segments.

4. Welding method

Concrete cutting blades typically use two welding methods: high-frequency welding and laser welding. We generally recommend laser welding because it provides superior strength and ensures that segments remain securely attached during cutting. However, if you are looking to reduce costs and are cutting concrete with low-density rebar, high-frequency welded blades can be a suitable alternative.

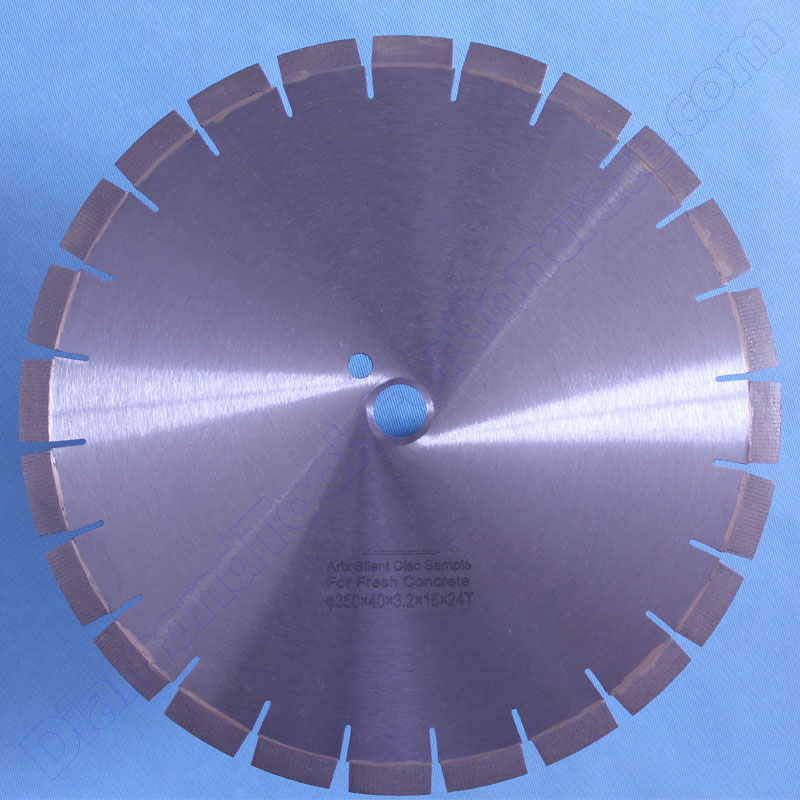

5. Silent or non-silent?

A silent concrete cutting blade features a specially designed silent core(also known as a blank blade). This core is engineered to significantly reduce the noise produced during cutting operations. By minimizing cutting noise, the blade creates a quieter working environment, which is beneficial both for operators and for surrounding areas. This reduction in noise can enhance operator comfort and help comply with noise regulations, making the cutting process more environmentally friendly and less disruptive.

6. Wet or dry?

Diamond blades can be classified into two types based on water usage during cutting: wet-cutting and dry-cutting blades. All concrete cutting blades are suitable for wet cutting, which is generally recommended because water helps cool the blade, protecting the segments and extending the blade’s lifespan. It also improves the removal of cutting chips. However, the downside is the need to clean up the mud left after cutting.

For dry cutting, you will need a blade specifically designed for this purpose, with a different diamond formula and laser welding. For instance, our Arix segmented concrete diamond saw blades are suitable for dry cutting. The drawback of dry cutting is the significant amount of dust it generates, so it’s important to control dust by using a vacuum or other dust management systems.

7. The power of your cutter

When purchasing concrete cutting blades, please provide the power specifications of your cutter or saw. We offer three different diamond formulas tailored to various power levels: High Power, Medium Power, and Low Power. This ensures that our concrete cutting blades are perfectly matched to your machine’s requirements for optimal performance.

Concrete cutting blades

Concrete cutting blades are essential for various projects. Xpert provides a range of diamond saw blades tailored for cutting concrete and reinforced concrete. We recommend our laser-welded blades for their versatility in handling any concrete cutting job, regardless of rebar density. Our largest laser-welded blade has a diameter of up to 1200mm. We offer various types of concrete diamond saw blades, including silent and Arix blades, with customizable connections to fit your specific cutting machines.

150mm & 200mm concrete cutting blades

230mm concrete cutting blades

350mm concrete cutting blades

400mm concrete cutting blades

Other sizes of concrete cutting blades

OEM service

We offer additional services for painting and laser engraving.

For end-users such as contractors, most do not require customized painting colors or logo engraving. In such cases, we proceed with standard painting and engraving procedures. However, most resellers seek to enhance brand visibility and recognition by customizing painting colors and engraving logos on tools.

Painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for Xpert Diamond Tools

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Laser engraving

Concrete cutting diamond saw blades typically feature several engraved labels providing key information, including the logo, blade diameter, arbor size, segment type, segment size and quantity, cutting material, maximum RPM, safety symbols, and part numbers. We offer customization of these labels to meet your specific requirements.

Payment methods and terms

Regarding the payment process for concrete cutting blades, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete diamond saw blades, we maintain a diverse inventory of different segments and cores(blank blade). Consequently, orders for these commonly used segments and cores can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Packaging

We offer various packaging options for our concrete cutting diamond saw blades based on size. Small blades come in fully transparent or white box packaging, medium blades are packed in white boxes, and large blades are enclosed in wooden boxes. For very large blades, we use iron frames. Regardless of the packaging method, we ensure that all blades are securely and firmly packaged to protect them during shipping.

Packaging for small blade

Packaging for medium blade

Packaging for large blade

Packaging for very large blade

Packaging of Medium Size Diamond Saw Blade

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods from the Air Port yourself | Door-to-door Door-to-CY(Container Yard) Door-to-CFS(Container Freight Station |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.