Table of Contents

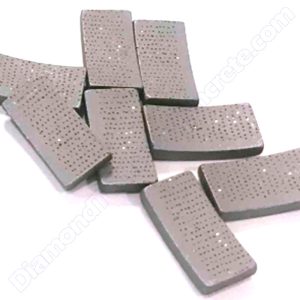

Concrete core bit segments are the functional parts of a concrete core drill bit. They are used for retipping the barrels. Compared to purchasing a whole core drill bit, retipping can save on both product and shipping costs, and recycling barrels is also beneficial for the environment. Therefore, if you have the necessary equipment for retipping core bit segments, it is an effective way to reduce costs.

6 things you may need to know

When purchasing concrete core bit segments, consider these six key factors to ensure you make the best choice for your specific needs.

1. Segment types

There are mainly two different types of concrete core bit segments: crown type and bar type. Crown core bit segments are designed for smaller diameters of core drill bits because they are easier to produce and weld. In contrast, bar-type segments are used for retipping larger core drill bits.

2. Segment shapes

For crown-type segments, the shape is generally uniform, with differences only in diameter. For bar-type core bit segments, Xpert Diamond Tools has developed eight different shapes for various performances: Normal, Roof, Turbo, Turbo+Zigzag, Turbo+Roof, Aero, Net+Roof, and Arix. The Arix concrete core bit segments are the sharpest, while the Normal type offers the most competitive performance. Roof and Turbo types are also very popular.

3. Segment sizes

Different types of concrete core bit segments suit different situations. Bar-type segments can accommodate a wider range of core drill bit diameters, with a specific core bit segment size compatible with a range. For example, one of our core bit segments is designed for a 60mm concrete core drill bit but can fit diameters ranging from 52mm to 66mm. In contrast, crown segments are typically used for only one specific diameter.

Size table of crown segment

| Segment Size (Diameter*Thickness*Height) |

Diameter of Core Drill Bits |

|---|---|

| 14*3.0*10mm | 14mm |

| 16*3.0*10mm | 16mm |

| 18*3.0*10mm | 18mm |

| 20*3.0*10mm | 20mm |

| 22*3.0*10mm | 22mm |

| 25*3.0*10mm | 25mm |

| 26*3.0*10mm | 26mm |

| 28*3.0*10mm | 28mm |

| 30*3.0*10mm | 30mm |

| 32*3.0*10mm | 32mm |

| 35*3.0*10mm | 35mm |

| 38*3.0*10mm | 38mm |

| 40*3.0*10mm | 40mm |

| 45*3.0*10mm | 45mm |

| 50*3.0*10mm | 50mm |

Size table of bar segment

| Segment Size (Length*Thickness*Height) |

Diameter of Core Drill Bits | |

|---|---|---|

| Designed | Suitable Range | |

| 16*3.0*10mm | 35mm | 32mm-36mm |

| 16*3.0*10mm | 44mm | 38mm-48mm |

| 24*3.5*10mm | 60mm | 52mm-66mm |

| 24*3.5*10mm | 76mm | 68mm-82mm |

| 24*3.5*10mm | 96mm | 84mm-108mm |

| 24*4.0*10mm | 140mm | 110mm-150mm |

| 24*4.5*10mm | 180mm | 160mm-200mm |

| 24*4.5*10mm | 228mm | 202mm-254mm |

| 24*5.0*10mm | 280mm | 260mm-300mm |

| 24*5.5*10mm | 350mm | 305mm-400mm |

| 24*5.5*10mm | 450mm | 405mm-500mm |

4. Segment quality

Different segment qualities use different diamond formulas. To meet the diverse needs of our customers, Xpert Diamond Tools offers three main grades of segment quality: Grade A, Grade B, and Grade C.

- Grade A uses cobalt formulas and features higher-standard diamonds. It is designed for drilling reinforced concrete with a high density of rebars.

- Grade B is designed for drilling reinforced concrete with a medium density of rebars.

- Grade C is designed for drilling new or green concrete with low-density rebar or brick walls.

We believe that there is no single best product, only the most suitable product. Therefore, choose the concrete core bit segments that best fit your drilling project.

5. Welding method

The welding method also needs to be confirmed when buying concrete core bit segments, as different methods require different welding bottom layers. We provide two different bottom layers: one for high-frequency welding or flame welding, and the other for laser welding.

We recommend using segments for laser welding when drilling reinforced concrete because it provides much higher welding strength. If you are drilling new or green concrete with low-density rebar, then high-frequency or flame welding is okay.

If you are interested in different welding methods, please check this article: 2 Diamond Tools Welding Methods: High-Frequency VS Laser.

6. Wet or dry?

Wet drilling

Dry drilling

Depending on whether water is supplied during the drilling process, it is categorized as either dry drilling or wet drilling. If conditions permit, wet drilling is recommended because it is more effective for cooling, removing concrete chips, and reducing dust, which improves drilling efficiency and extends the tool’s life. The only drawback is that the mud needs to be cleaned up after completion.

Dry drilling is suitable for situations where there is no water supply or it is inconvenient to clean up the mud, and a vacuum cleaner is required. The concrete core bit segments used for dry drilling are of higher quality (cobalt formulas) because they need to withstand higher temperatures.

Concrete core bit segments

Concrete core bit segments are a crucial component of concrete core drill bits, playing a key role in the efficiency and effectiveness of drilling operations. We offer two distinct types of segments for retipping the barrels: Crown type and Bar type.

Crown-type core bit segments

Crown core bit segments are specifically designed for core drill bits with diameters under 50mm. Each crown segment size is carefully engineered to match precisely with its corresponding barrel, ensuring a perfect fit and optimal performance. The unique ring design of these segments significantly simplifies the retipping process for the operator, making it more efficient and user-friendly. Additionally, the strategically placed slots on the segments play a crucial role in enhancing drilling efficiency. These slots facilitate the effective removal of cutting chips, reduce the contact area between the segment and the material being drilled, and contribute to smoother operation.

Bar-type core bit segments

We primarily offer eight different bar-type concrete core bit segments for drilling concrete and reinforced concrete, including the Arix segments. Concrete drilling is a gradual process, and each design impacts drilling performance differently, including factors such as drilling speed, lifespan, positioning, and stability.

Accessories

When retipping concrete core bit segments, it is easier to position the segments using a magnet tool. This tool firmly secures the segments on the barrel, making it simple to use.

Segment magnet tool for retipping barrels

Elevate your brazing skills with ease—this brazing magnet lowers the barrier for creating high-quality diamond core drill bits, allowing anyone to achieve expert results. It improves the efficiency of soldering diamond core bits, accelerating your workflow. Designed for precise positioning, this magnet ensures diamond core bit segments are perfectly aligned on barrels, resulting in more accurate drilling. Its innovative design features four adjustable side clearances, accommodating all diameters of diamond core drill bits. Additionally, the brazing magnet is reusable and durable, making it an economical and eco-friendly choice for frequent use.

Payment methods and terms

Regarding the payment process for concrete core bit segments, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete core bit segments, we maintain a diverse inventory of different carbide rollers and blank plates compatible with common floor grinding machines like HTC, Lavina, Husqvarna, Blastrac, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Packaging

Our packaging method ensures that segments are fully protected during shipping through a secure, multi-step process. First, we wrap the specified quantity of segments in yellow paper. Next, we seal them with yellow tape, which provides waterproof protection. The wrapped segments are then placed into a sturdy box with foam padding to safeguard them during transit. Finally, this hard box is packed into a larger carton or wooden box for additional protection.

1. Wrap segments with yellow paper

2. Wrap yellow tape around the outside

3. Put the segments into a hard box as the smallest package

4. Put the smallest package into a carton or wooden box

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods from the Air Port yourself | Door-to-door Door-to-CY(Container Yard) Door-to-CFS(Container Freight Station |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.