Table of Contents

Bush-hammered profiles or finishes are widely appreciated for their decorative applications on various stones such as granite and marble. This finish is known for enhancing the natural beauty and texture of the stone, making it a preferred choice for aesthetic enhancements.

When applied to concrete floors, bush hammering offers a range of practical benefits. It can be utilized to create textured surfaces that enhance the visual appeal and functionality of the flooring. Additionally, it is highly effective for surface preparation tasks, such as removing existing coatings, which is essential for ensuring a clean and ready surface for subsequent treatments. Moreover, bush hammering is instrumental in creating non-slip surfaces, thereby improving safety in areas prone to moisture or heavy foot traffic. It is also a valuable technique in restoration work, aiding in the rejuvenation of old or damaged concrete surfaces.

6 things you may need to know

The functional part of a bush hammer can be tungsten carbide, vacuum-brazed diamonds, or PCDs. For concrete bush hammering, we mainly use tungsten carbide tips, and there are 6 things you may need to know before buying concrete grinding bush hammer tools from us.

1. Quality of carbides

For the tungsten carbides, there are many different grades. Among these grades, YG8 is very suitable to be used on bush hammers. Below are some reasons:

- Hardness: YG8 carbide has a high hardness level, making it ideal for creating the rough, textured surface needed in bush hammering. This hardness allows it to withstand the abrasive action required in surface preparation.

- Wear Resistance: YG8 offers excellent wear resistance, which is crucial for tools like bush hammers that are subjected to continuous impact and friction against hard surfaces.

- Impact Resistance: YG8 carbide has a balanced combination of hardness and toughness. This balance ensures that the carbide can endure the repeated impacts of bush hammering without chipping or breaking.

- Longevity: The toughness of YG8 contributes to the longevity of the bush hammer tool, reducing the frequency of replacements and maintenance.

2. Types of carbide tips

Conical carbides

Tri-Edge carbides

Different types of carbide tips create various bush hammer finishes. We use two types of carbides in our concrete bush hammers: Conical and Tri-Edge. Conical carbides, also known as point type, are the classic type used in bush hammers. Tri-Edge carbides have three edges and create coarser bush hammer profiles on the concrete surface.

3. Sizes of carbide tips

4.7mm, 6mm, and 8mm conical carbides

6mm Tri-Edge carbides

Bush hammer profiles on the surface of concrete consist of various holes or grooves. The size of the carbide tips determines the width and depth of these grooves. We provide three different sizes of point carbides: 4.7mm, 6mm, and 8mm, and one size for tri-edge carbides: 6mm. Larger carbide sizes result in coarser textures on the surface.

4. Quantity of carbide tips per roller

For conical carbides, there are 3 commonly used quantities per roller: 30 tips, 45 tips, and 60 tips. For tri-edge carbides, we offer 11 or 15 pieces per roller. The quantity of the carbides doesn’t affect the depth of the bush-hammered profile, but rather its density. A higher quantity of teeth results in a denser bush-hammered profile. If you prefer a sparser bush-hammered profile, opt for a roller with fewer carbide tips. For a denser bush hammer profile, choose a roller with more carbide tips.

30 conical carbides per roller

45 conical carbides per roller

60 conical carbides per roller

5. Layout of tungsten carbides

30 conical carbides layout A

30 conical carbides layout B

Although the quantity of carbides per roller is the same, they may have different layouts. For instance, of the 30 conical carbide rollers, there are primarily two different layouts: A and B.

In layout A, the distance between each carbide head is farther apart, whereas in layout B, they are closer together, resulting in different performance characteristics. Layout B is more aggressive than layout A, making it ideal for deeper exposure of aggregate and moving thick and stubborn coatings. Layout A, on the other hand, is better suited for general use and has higher efficiency.

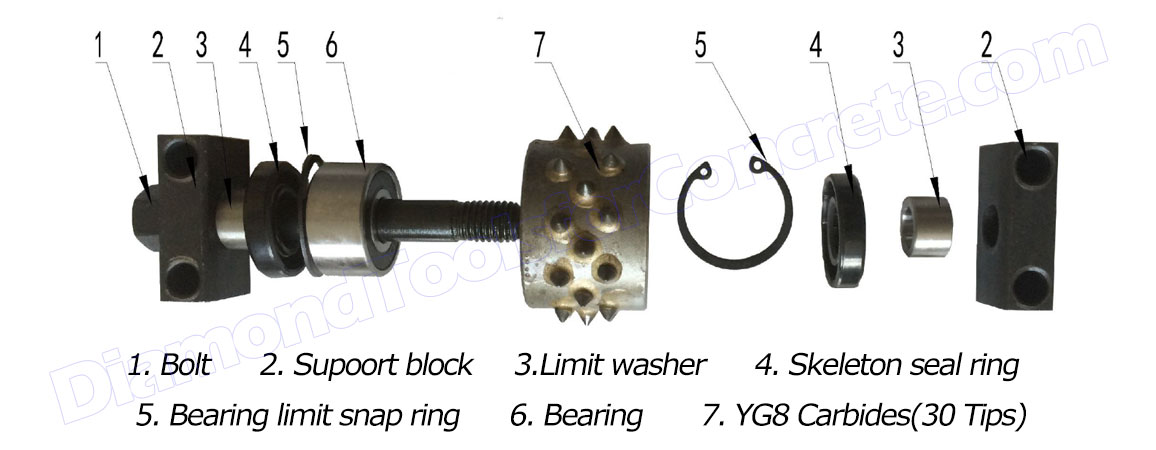

6. Structure of carbide rollers

As a bush hammer, aside from the carbides, the structure of the carbide roller is also crucial. Xpert Diamond Tools uses high-quality materials for bearings, skeleton seal rings, bolts, etc., and optimizes the structure of carbide rollers. This enhances their strength and dustproof capabilities, ensuring stable performance and extending their lifespan.

Concrete bush hammers for angle grinders

We developed different concrete bush hammers for angle grinders and floor grinders. With an angle grinder, bush hammering is very flexible. You can use it on both concrete floors and concrete walls. With floor grinders, the bush hammer is used only on the floor, but with very high efficiency.

For concrete bush hammers used on Angle Grinders, we mainly offer 2 types as below.

125mm double layers bush hammer plate

This 125mm 2-layer bush hammer is one of the most popular bush hammer plates for angle grinders. It comes with 3 carbide rollers and can be used for various applications.

- Easy to control and operate.

- Great for grinding narrow spaces.

- Great for grinding concrete, granite, marble, and other construction materials.

- Can be used for removing floor coatings like paint, glue, etc.

- The springs between 2 layers can reduce the vibration and lengthen its lifespan.

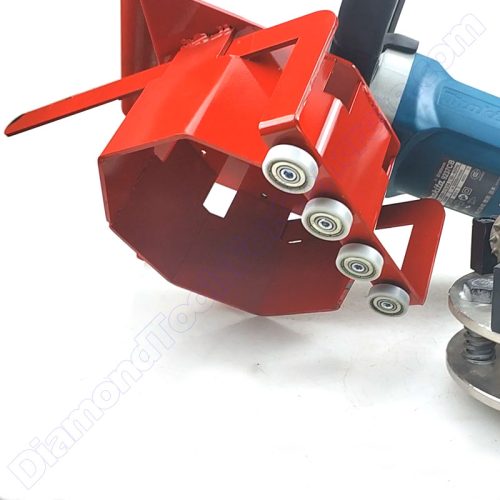

150mm bush hammer plate

This 150mm bush hammer plate has a different design compared to other types. The carbide rollers are inside the plates, and we need a steel cover to protect the tools. On one hand, the steel cover can ensure safety during bush hammering. On the other hand, it includes a hole to connect a vacuum cleaner. If you require a dust-free environment, then this one is a good choice.

- Highly efficient grinding for concrete, granite, marble, and other materials.

- Great for grinding in narrow spaces.

- Works well with a vacuum cleaner.

- Increased safety with a steel cover.

- Easy operation with a rubber handle.

Concrete bush hammers for floor grinders

As a concrete grinding tools expert, Xpert Diamond Tools has developed various diamond tools used on floor grinding machines, including metal bond concrete grinding diamonds, PCD floor coating removal tools, resin bond concrete polishing pads, and bush hammer tools. To meet the diverse requirements of our customers, we manufacture different types of concrete bush hammers suitable for various brands of floor grinding machines, such as Lavina, HTC, Husqvarna, Klindex, ASL, PHX, Frankfurt, and Trapezoid-type bush hammers for universal use.

HTC bush hammers

For concrete bush hammers used on HTC floor grinders, we mainly provide 270mm HTC bush hammer plates with 6 carbide rollers. There are 2 rollers that are optional: 30 or 45 carbide tips per roller. 30 carbide tips are more aggressive than 45 tips, while 45 tips offer higher efficiency and productivity.

- Fits HTC floor grinders perfectly.

- Efficently grinding concrete floors to create bush-hammered profiles, non-slip surfaces, and remove floor coatings.

- Long lifespan with high-quality carbide rollers.

- optional 30 or 45 tips per carbide roller.

- Replacement rollers are supplied.

Lavina bush hammers

These Lavina quick-change concrete bush hammer tools are designed to create a bush-hammered profile on concrete. They are also excellent for removing thin coatings in preparation for epoxy application.

- Compatible with any electric LAVINA grinder and other grinders with a QuickChange adapter plate.

- Excellent for concrete stripping, cleaning, and profiling, as well as exposing large aggregates.

- Ideal for exterior spaces and creating anti-slip surfaces.

- Great for removing thin coatings in preparation for epoxy application.

Husqvarna bush hammers

There are 3 different types of Husqvarna concrete bush hammers supplied. Two of them have the same design of a round mounting plate but different carbides. The last one has a more compact design with a square mounting plate.

Compared to the complete assembly of Husqvarna bush hammer plates, these single bush hammer heads can be directly used on your Husqvarna floor grinders with the redi-lock quick-change system. They are also lighter, which can save on shipping costs.

These ultra-aggressive prep tools are designed to pulverize the surface of concrete, making it fast and easy to achieve full aggregate exposure. Whether for surface preparation, coating removal, or achieving the desired texture, our bush hammers for grinders are reliable and efficient solutions for enhancing concrete surfaces.

4.7 conical carbides with round base

6.0mm tri-edge carbides with round base

Klindex bush hammers

4.7mm conical carbides – B

6mm tri-edge carbides

These 4 types of 240mm concrete bush hammer plates are designed for Klindex floor grinders. The backs of the plates have 3 pins for connection. They are designed for bush hammering floors made of concrete, granite, marble, and other stones. They feature 4.7mm conical carbides for creating fine profiles, 6.0mm conical carbides for medium profiles, and 6.0mm tri-edges for coarse profiles.

These bush hammer plates deliver exceptional results, making them an ideal choice for surface preparation, texturing, and removing coatings.

- Constructed from premium materials to ensure long-lasting performance and resistance to wear.

- Fit seamlessly with Klindex floor grinders, providing smooth and efficient operation.

- The 240mm size offers a perfect balance between coverage and maneuverability, allowing efficient work on large areas.

- Perfect for creating a non-slip surface, exposing aggregate, and removing old coatings and adhesives.

ASL bush hammers

This trapezoidal concrete bush hammer is equipped with 30 conical carbides, designed to deliver superior performance and efficiency on ASL walk-behind grinders.

It is engineered to pulverize the surface of concrete, making it quick and easy to achieve full aggregate exposure.

- Fits perfectly with Lavina floor grinders.

- Creates evenly textured anti-slip surfaces.

- Ideally exposes aggregates and leaves an even and textured new substrate for surface preparation.

- Aggressively removes thick and gluey coatings, such as elastic epoxy, carpet glues, asphalt, etc.

PHX bush hammers

PHX floor grinders use a quick-change system to allow the operator to change the tools easily and quickly. These concrete bush hammers are designed for PHX floor grinders for floor preparation, creating a non-slip surface on concrete floors, or removing floor coatings.

- Specially designed for PHX floor grinders.

- Hassle-free to change the bush hammers.

- YG8 high-quality carbide tips are used for better performance.

- Dust-proof design for longer lifespan.

Frankfurt bush hammers

6mm conical carbides

6mm tri-edge carbides

Frankfurt-type bush hammers are more commonly used on stone grinding machines to create textured surfaces on stones like granite, marble, etc. However, they can also be used on some floor grinders like Stonker and Aztec, and other floor grinders with the correct adapters.

We provide 4 different types of Frankfurt bush hammers: 3 different sizes of conical carbide types and 1 tri-edge type, for making bush-hammered profiles on the surface of concrete, surface preparation, exposing aggregates, and creating anti-slip surfaces. They are also great for removing floor coatings like paint lines, markings, and other coatings.

- Frankfurt-type quick change makes it simple to change.

- Hollowed steel base reduces the weight and decreases power consumption, saving energy.

- Designed for texturing the concrete surface to expose aggregates, preparing the floor for the next step.

- Creating a non-slip surface on the floor.

- Great for removing floor coatings like paint lines, lines markings, etc.

Accessories for replacement

Each carbide roller of the bush hammer tools above is supported separately for replacement. For the 150mm angle grinder bush hammer plate, we provide different types of steel covers to choose from: normal type, and one available with a vacuum cleaner. After testing our tools, for regular orders, we suggest keeping some carbide rollers in stock for replacements. This can save you costs and time.

- Easy to make replacement

- Competitive price

- Original factory quality

- Saves your cost on the bush hammer tools

- allows for immediate repairs, minimizing downtime.

Payment methods and terms

Regarding the payment process for concrete bush hammer tools, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For concrete grinding bush hammer tools, we maintain a diverse inventory of different carbide rollers and blank plates compatible with common floor grinding machines like HTC, Lavina, Husqvarna, Blastrac, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Packaging

The carbide tips of the bush hammers are very hard but brittle. Therefore, we use very secure packaging for our concrete bush hammers to ensure that all goods arrive intact. Most of our bush hammer tools are packaged as follows: a hard green box filled with EPE pearl cotton. For smaller bush hammers such as Lavina, ASL, etc., we package them 3 pieces per box. For larger bush hammer tools, each piece is individually boxed.

Angle grinder bush hammer plate

Frankfurt bush hammer tools

Lavina bush hammer tools

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods yourself or Door-to-door service |

Pick up the goods yourself or Door-to-door service |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.

Cautions

There are some cautions when using concrete grinding bush hammers.

- Avoid applying excessive pressure on the bush hammer to prevent hindering the roller bearing’s functionality and shortening the lifespan of the tungsten carbides.

- Ensure regular maintenance and cleaning to keep the tool in optimal condition.

- Use appropriate safety gear when operating the bush hammer to protect yourself from potential hazards.

- Inspect the tool before each use to check for any signs of damage or wear.