Diamond Segments Fact: Performance Bigger than Appearance

December 17, 2024

Notice of Chinese New Year Holiday

January 24, 2025On the Mohs scale of hardness, which ranges from 1 to 10, human tooth enamel scores around 7–8, making it the hardest part of the human body. In the industrial world, there exists a material so hard that it is aptly called the “industrial tooth.” What is this material, and how hard is it?

Diamonds: Nature’s Toughest Creation

On the Mohs scale, this “industrial tooth” tops out at a perfect 10, signifying that it is the hardest substance known in nature. You’ve guessed it: it’s the diamond. In addition to unparalleled hardness, diamonds also possess remarkable thermal, optical, acoustic, and electrical properties. These characteristics make diamonds indispensable in industries ranging from aerospace and defense to petroleum exploration and semiconductor manufacturing.

Diamonds are not only cherished for their brilliance in jewelry but also valued for their extraordinary performance in industrial applications. Their ability to withstand extreme conditions while maintaining superior efficiency makes them the ultimate solution for challenging tasks.

The Development of Synthetic Diamonds

In the late 1950s, China faced a severe shortage of natural diamonds, relying heavily on imports. Economic and technological blockades imposed by the West almost completely cut off this supply, creating a critical bottleneck for industrial development. The solution lay in synthetic diamonds—an alternative to natural ones.

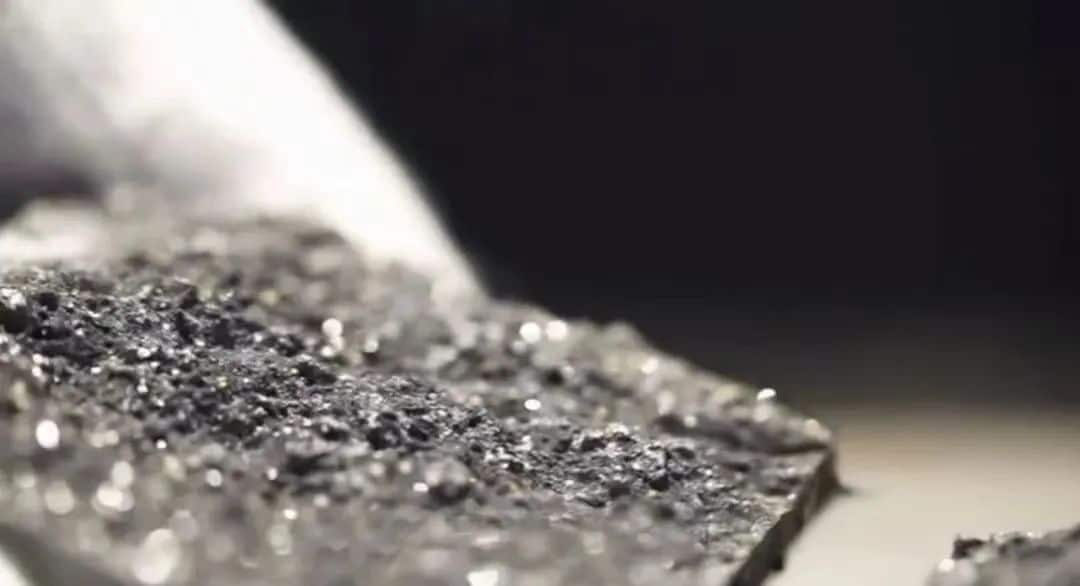

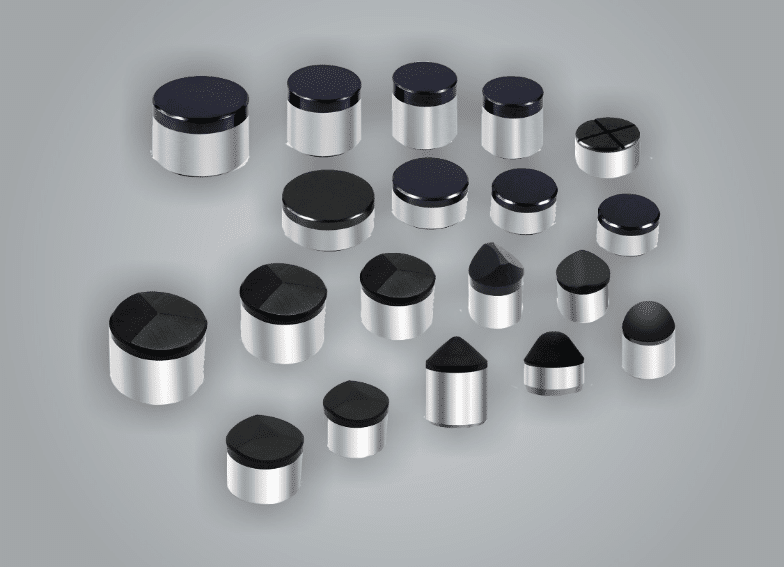

Synthetic Diamond Grit Sintered Block

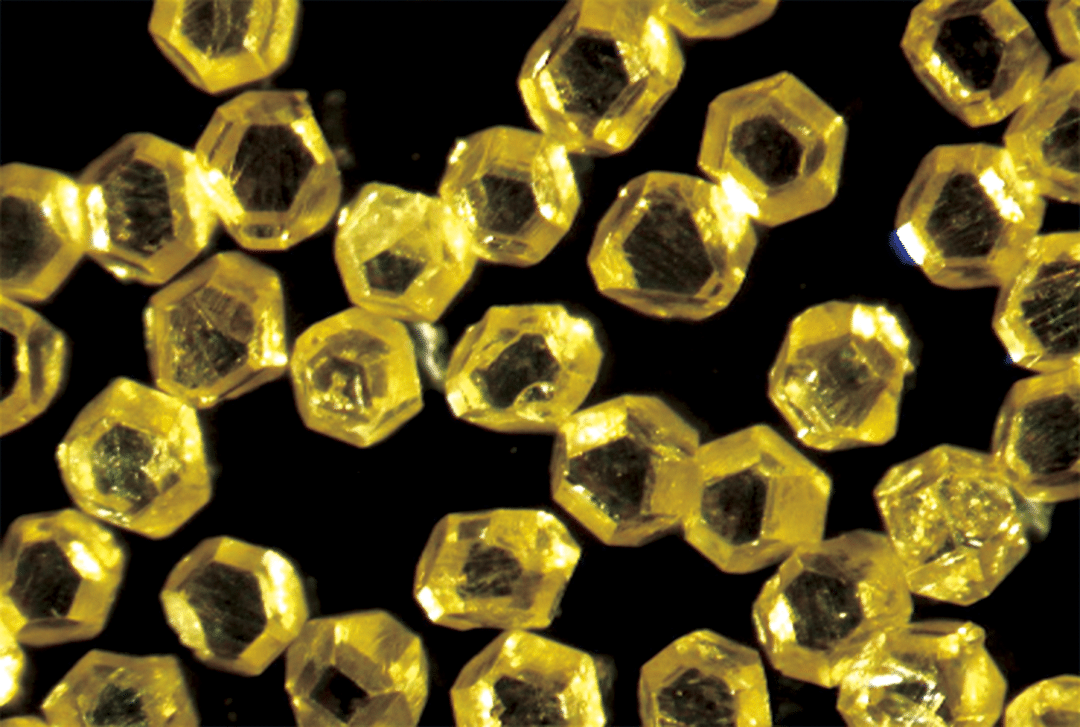

Both diamonds and graphite are forms of carbon, but the production of synthetic diamonds involves transforming graphite into diamonds under extreme heat and pressure. In 1963, after years of experimentation and setbacks, China successfully produced its first batch of synthetic diamonds, becoming the sixth country in the world to master this technology. The initial efforts involved innovative methods like high-pressure presses and precise thermal control to replicate natural diamond formation conditions.

In 1963, Beijing, China successfully synthesized synthetic diamonds for the first time.

This milestone marked the beginning of a revolution in industrial applications. Synthetic diamonds quickly became essential for manufacturing processes that demanded extreme hardness and durability. By 2023, China’s synthetic diamond production had exceeded 25 billion carats, accounting for over 95% of global output. This achievement not only ensured self-sufficiency but also established China as a global leader in diamond production.

Diamonds Powering Modern Industries

Products for the petroleum drilling industry are widely used in deep wells, ultra-deep wells, deep-sea oil, shale gas, and other complex, hard-to-grind geological formations for oil and gas drilling and extraction.

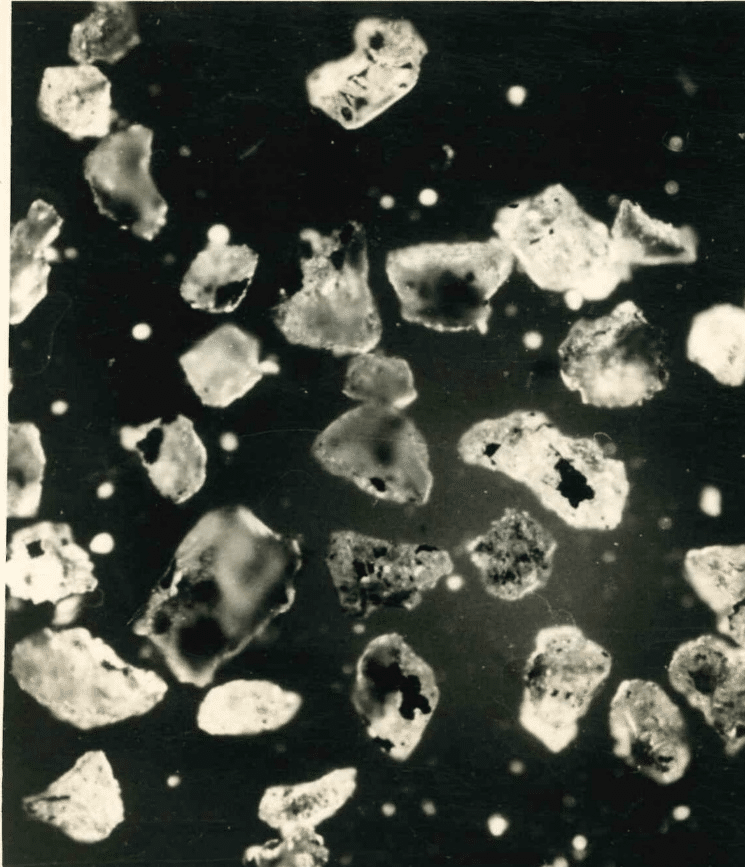

Synthetic diamonds now play a pivotal role in numerous fields. From deep-earth drilling and aerospace exploration to photovoltaic energy and IC chip manufacturing, these “industrial teeth” tackle the toughest challenges. For instance, in petroleum exploration, diamond drill bits cut through the hardest rock layers, ensuring efficient extraction. In the semiconductor industry, diamond coatings enhance the precision and lifespan of critical components, contributing to technological advancements.

SEM image of synthetic diamond particles

Moreover, the eco-friendly production methods of synthetic diamonds have significantly reduced the environmental impact compared to mining natural diamonds. This aligns with global sustainability goals and further elevates their industrial value.

Explore Cutting-Edge Diamond Tools

At Xpert Diamond Tools, we leverage the exceptional properties of diamonds to create tools that redefine industrial performance. Our products are meticulously designed to meet the demands of various concrete applications:

- Concrete Cutting Tools: Designed for precise and efficient cutting, our tools handle the toughest concrete projects with ease. From highways to industrial floors, these tools ensure sharp, clean cuts with minimal downtime.

- Concrete Grinding Tools: Featuring durable segments and superior grinding efficiency, these tools ensure a smooth finish for any concrete surface. Whether preparing surfaces for coatings or restoring worn-out floors, our grinding tools deliver unmatched performance.

- Concrete Drilling Tools: Equipped with advanced diamond segments, our drilling tools achieve faster penetration and extended lifespan. Perfect for core drilling tasks, they combine precision and durability for diverse applications.

Our commitment to innovation ensures that each tool meets the highest industry standards. Whether you’re involved in construction, renovation, or specialized drilling projects, Xpert Diamond Tools provides solutions tailored to your needs.

Contact us today to learn how our diamond tools can enhance your operations. Let us help you achieve excellence with the toughest “teeth” in the industry.