World of Concrete 2025: Shaping the Future in Las Vegas

October 18, 2024

The Hardest Material in Nature: Diamonds—The “Teeth” of Industry

December 20, 2024Unlike general goods, the performance of diamond segments matters more than their appearance. — Wendy from Xpert Diamond Tools

The appearance of a product is an important factor, but its significance varies depending on the type of product. For example, for items like jewelry or clothing, appearance plays a major role. However, when it comes to diamond segments, performance is the top priority, which can only be determined through testing.

A visually appealing segment might attract more leads, but it has no connection to actual cutting efficiency. You may purchase diamond segments from a manufacturer that look impressive, but if they fail to cut effectively, the attractive appearance has misled you into making a poor decision. On the other hand, a segment that appears plain or unimpressive could deliver excellent cutting performance—and without a doubt, you would prefer such a product.

Of course, the ideal scenario is a diamond segment that not only looks great but also performs exceptionally well. For distributors, this combination ensures more product inquiries and orders.

Introduction

Diamond segments are the critical components of cutting, grinding and drilling tools, designed to handle tough materials like concrete, stone, and asphalt. Their performance directly impacts the efficiency, speed, and lifespan of the tools they’re attached to. However, many people mistakenly judge the quality of a diamond segment by its appearance. While aesthetics may grab attention, true performance lies in the technical design and material composition. This article delves into why performance matters more than looks when it comes to diamond segments.

Concrete Cutting Segments

Concrete Grinding Segments

Concrete Drilling Segments

Understanding Diamond Segment Performance

The performance of a diamond segment depends on a combination of factors, each carefully engineered to ensure optimal cutting or grinding efficiency. Here are the key elements:

- Material Bond: The bond refers to the metal matrix that holds the diamonds in place. A properly formulated bond ensures that diamonds are exposed at the right rate during cutting or grinding. For instance, softer bonds work better on harder materials, while harder bonds are ideal for softer materials.

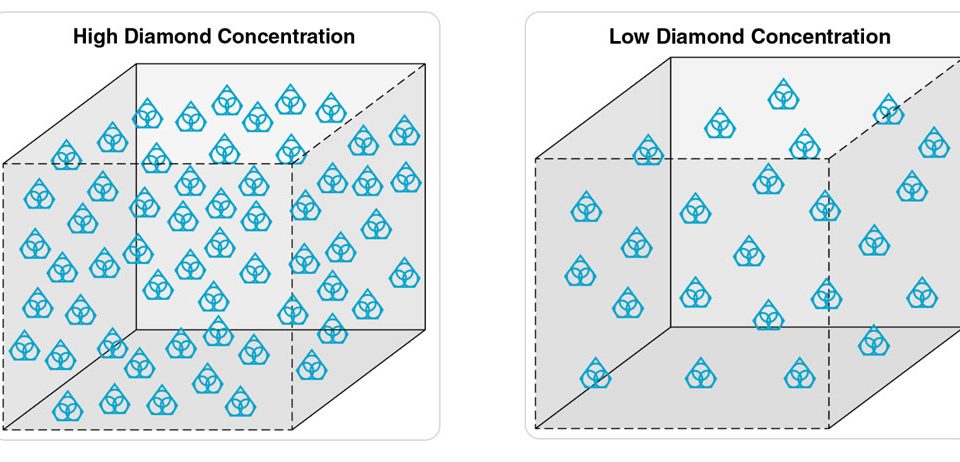

- Diamond Concentration: The concentration of diamonds in a segment determines how aggressively it can cut. Higher diamond concentrations often lead to better performance, but the ideal balance depends on the material being processed. (If you want to know more about diamond concentration, you can check our other article: What Is Diamond Concentration and Why Can It Reach 100%? )

- Segment Design: From flat segments to specialized designs like roof or crown segments, the structure plays a significant role in performance. Innovative designs optimize cutting speed, debris clearance, and cooling.

These technical aspects far outweigh the visual appeal of a segment. A plain-looking segment with superior engineering can outperform one that appears impressive but lacks functionality.

Why Appearance Can Be Misleading

It’s easy to assume that a flashy, well-polished segment will deliver better results, but this is often not the case. Appearance can be deceptive for several reasons:

- Visual Features Don’t Guarantee Quality: Many manufacturers focus on creating aesthetically pleasing products to attract buyers. However, these features don’t necessarily reflect the segment’s durability or performance.

- Real-World Testing Tells the Truth: The true quality of a diamond segment emerges only after rigorous testing. Factors like cutting speed, precision, and lifespan are the real indicators of a high-performing segment, not its appearance.

For example, a segment with a sleek finish may fail under heavy-duty usage, while a plain-looking segment might excel in cutting through tough materials with ease. Users should prioritize function over form to avoid disappointment.

Innovative Designs Beyond Looks

In the diamond tool industry, manufacturers focus on creating functional designs that enhance performance. Below are some examples of innovative designs that demonstrate how engineering trumps aesthetics:

- Roof Segments: These segments are designed for faster penetration into hard materials. Their unique shape minimizes resistance, allowing for smoother cutting action. They prioritize performance over visual appeal.

- Crown Segments: Crown segments are favored for their precise fit and superior welding compatibility with barrels. Their engineering ensures even wear and enhanced cutting efficiency.

- Drop Segments: Drop segments are used in asphalt cutting blades to improve cutting speed and longevity. Their performance-oriented design allows them to handle challenging conditions better than standard segments.

- Arix Segments: Arix Segments are advanced diamond segments designed for superior cutting performance. Featuring evenly distributed diamonds in a precise pattern, they ensure faster cutting speeds, longer tool life, and enhanced efficiency. Ideal for demanding applications like concrete, stone, and asphalt cutting, Arix segments deliver consistent performance and reliability.

These designs show that innovation in segment technology focuses on delivering results, not just looking impressive.

Customer Education and Awareness

Many users, especially those new to diamond tools, may not know how to evaluate segments effectively. Here are some tips to help customers make informed decisions:

- Look Beyond the Surface: Evaluate a segment based on its specifications, such as bond type, diamond concentration, and intended application. Don’t be swayed by a polished or decorative finish.

- Ask for Test Results: Reputable manufacturers often provide performance data or test results for their products. These metrics, such as cutting speed and material removal rate, give a clearer picture of a segment’s quality.

- Consult Experienced Manufacturers: Working with trusted manufacturers such as Xpert Diamond Tools ensures access to high-quality segments tailored to your needs. They can recommend the right product based on the material and application.

- Trial and Feedback: Testing a small batch of segments before a bulk purchase can provide firsthand experience of their performance. Provide feedback to the manufacturer to refine your selection.

Conclusion

When it comes to diamond segments, performance truly matters more than appearance. Factors like material bond, diamond concentration, and innovative design determine how well a segment performs, not how it looks. While visually appealing products may catch your eye, their functionality often falls short if not engineered properly. By focusing on technical specifications and real-world testing, customers can make better decisions and achieve superior results in their cutting and grinding projects.

Remember, in the world of diamond segments, performance is always bigger than appearance.