What Exactly is the Arix Diamond Segment?

June 9, 2024

2024 Marmomac Stone Fair: September 24-27 in Verona

September 3, 2024Table of Contents

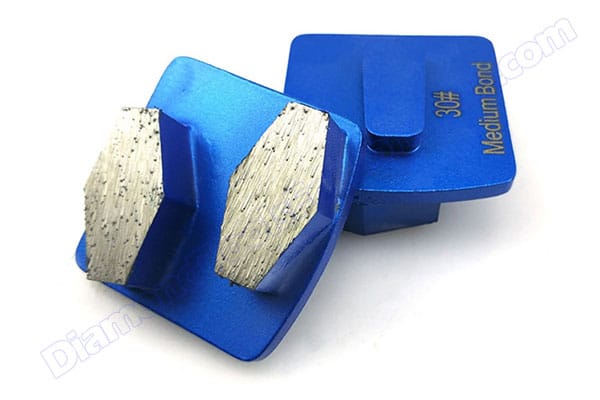

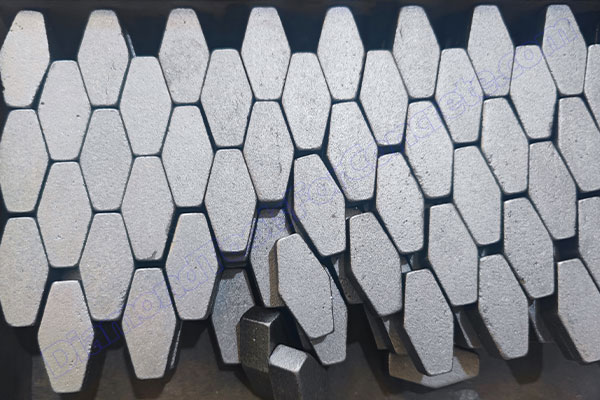

Concrete grinding segments are the functional part of metal bond concrete grinding diamond tooling. They come in various shapes such as rectangles (bars), arrows, rounds (buttons), ovals, hexagons, and more. These segments have different diamond grits and bonds, suitable for various levels of grinding and different hardnesses of concrete.

As a professional concrete grinding diamond tooling manufacturer, we also provide concrete grinding segments separately. But do you know what the three basic factors that affect the price are? The answer is Segment Formula, Segment Shape, and Segment Height. Let’s explore each one.

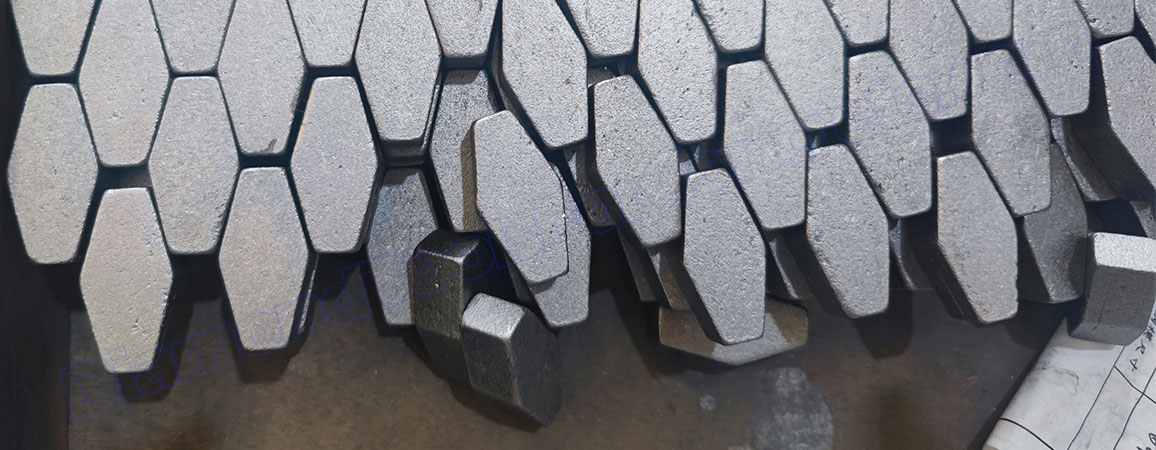

Some customers also refer to the complete concrete grinding diamond tooling as concrete grinding segments. To avoid misunderstanding, in this article, concrete grinding segments refer to the segments only (without the steel base). Please check the photos below.

Concrete grinding diamond tooling

Hexagon concrete grinding segments

Segment formula

When we talk about diamond segments, one of the most important aspects is the segment formula. Only segments with the right formula can satisfy customers’ specific applications of cutting, grinding, and drilling. For example, we can’t use granite cutting segments for concrete, as it will yield poor results.

As one of the types of diamond segments, concrete grinding segments also have different formulas. There are mainly two parts to the grinding segment formula: diamond particles and bonds. They are the first factor that affects the price.

Diamond particles

The diamond particles in diamond tools are artificial and come in different shapes, sizes, and qualities. The cutting and drilling intensity is greater, so the requirements for diamond particles are higher, as is the cost. The cost of diamond particles used for cutting is higher than those used for grinding.

Diamond shapes

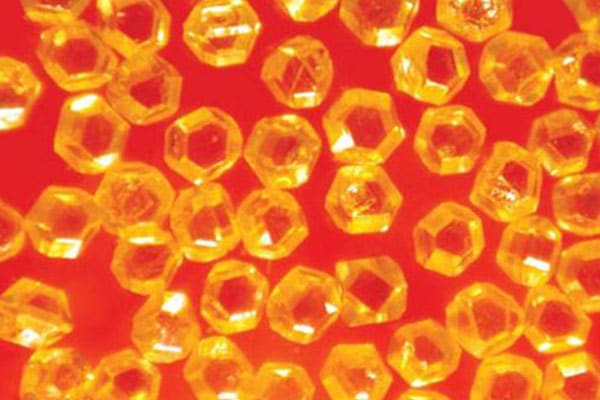

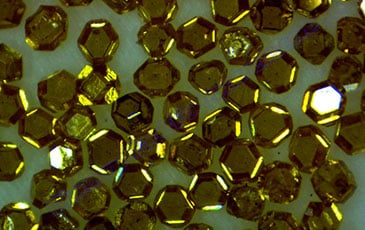

Compared with diamonds used for cutting or drilling, grinding diamonds have a flatter shape, which leaves fewer scratches on the surface of the concrete floor. While we can recognize this difference by eye, it is easier with the help of a microscope.

Diamond particles for cutting

Diamond particles for grinding (Flat type)

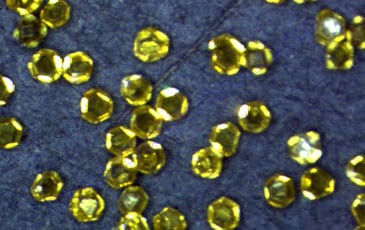

Diamond sizes (grits)

Diamond sizes are well known as diamond grits, a unit of measurement used to express the size of diamond particles. You may notice that we almost never mention the diamond grits of tools used for cutting and drilling, such as diamond saw blades, diamond wires, and diamond core drill bits. This is because they are not optional, and factories have their default diamond grits for cutting and drilling. However, for concrete grinding, customers need different processes for grinding or polishing, so it is essential to choose the right diamond grits.

40-45 diamond grits

35-40 diamond grits

30-35 diamond grits

Xpert Diamond Tools provides a wide range of diamond grits: 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, and 220#. The smaller the grit number, the larger the size of the diamonds, and consequently, the higher the cost.

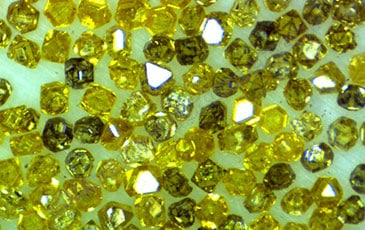

Diamond qualities

Even with the same diamond shapes and grits, diamond particles can vary in quality. The quality requirements for diamond particles used in grinding are not as stringent as those for cutting and drilling, but they still affect the grinding performance. We use top-quality diamond particles supplied by leading domestic companies in our concrete grinding diamond tooling to ensure optimal grinding performance and lifespan.

Grade A diamonds

Grade B diamonds

Grade C diamonds

Bonds(Bonding agency)

Segment bonds are also called bonding agents. They consist of different metals like Fe(Iron), Cu(Copper), Ni(Nickel), etc., to hold the diamond particles. During concrete grinding, the bonds must be consumed to expose the diamond particles for grinding or polishing. Since concrete varies in hardness and abrasiveness, different types of bonds are needed to suit different types of concrete. Xpert Diamond Tools mainly provides 6 bond types for grinding various hardness levels of concrete. Please refer to the chart below for details.

Concrete hardness and corresponding diamond bonds

| Concrete Hardness | Extremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| MOH’S | 7-9 | 5-7 | 4-5 | 3-4 | 2-3 | 1-2 |

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Bond Type | Extremely Soft Bond | Very Soft Bond | Soft Bond | Medium Bond | Hard Bond | Very Hard Bond |

| Bond Codes | XSB | VSB | SB | MB | HB | VHB |

| Floor Codes | XHF | VHF | HF | MF | SF | VSF |

| Color Represented |

Actually, the costs of different bonds are different: Softer bonds generally cost more. However, for simplicity in the calculation, we currently offer the same price for all of our six bond types.

Segment shape

Segment shape is another factor that affects the cost of concrete grinding segments. The basic shapes are rectangle (bar), arrow, and round (button). Based on these, various shapes have been developed for different purposes. One reason is that resellers want to make their tools unique and recognizable in the market, which is beneficial for promoting their brands. Another reason is that different shapes may have varying grinding performances. For example, according to feedback from our customers, the arrow-shaped segment leaves deeper scratches on the surface and pairs better with smaller diamond grits for more aggressive grinding.

Rectangle(Bar)

Arrow

Round(Button)

Oval

Why do different shapes of concrete grinding segments have different prices? It’s due to the differences in molds used during segment production.

So far, Xpert Diamond Tools has developed numerous different shapes of concrete grinding segments to meet the varied requirements of our customers. For end-users like concrete grinding contractors, you can simply choose from our existing range of shapes. For resellers interested in customizing unique shapes, you are welcome to do so. We have extensive experience with OEM/ODM orders and can find the best solutions for you.

Segment height

Segment height also affects the price of concrete grinding segments. It’s easy to understand: the higher the segment height, the larger the volume of segments and the longer their lifespan, which inevitably leads to a higher price.

12mm segment height

15mm segment height

Besides, there is another reason. Most factories have their default heights for concrete grinding segments. At Xpert Diamond Tools, except for several shapes, most of our concrete grinding segments are 10mm or 12mm in height. If you want to customize other segment heights, we need to open new molds, which will also incur extra costs.

If you are an end-user like a concrete grinding contractor, we recommend checking out another article: “3 Benefits of Higher Concrete Grinding Segments,” especially to learn why higher segments can save on shipping costs.

Conclusion

There are mainly three factors that affect the price of concrete grinding segments: Segment Formula, Segment Shape, and Segment Height. As a buyer, when comparing prices of the same concrete grinding diamonds from different suppliers, don’t forget to compare these segment aspects: diamond grits, bonds, and segment height (size). If you want to customize different shapes of concrete grinding segments, the price will be higher as you need to open a new mold.