2 Diamond Tools Welding Methods: High-Frequency VS Laser

May 3, 2024

270mm HTC Bush Hammer Plate Case From Norway

June 7, 2024Table of Contents

Concrete grinding segments are the functional part of the floor grinder diamond tooling, for grinding & polishing concrete, terrazzo floors, or other stone floors. There are lots of different brands of floor grinding machines in the markets, including HTC, Husqvarna, Lavina, Klindex, EDCO, ASL, and more. To match them, different types of diamond tooling are designed and manufactured.

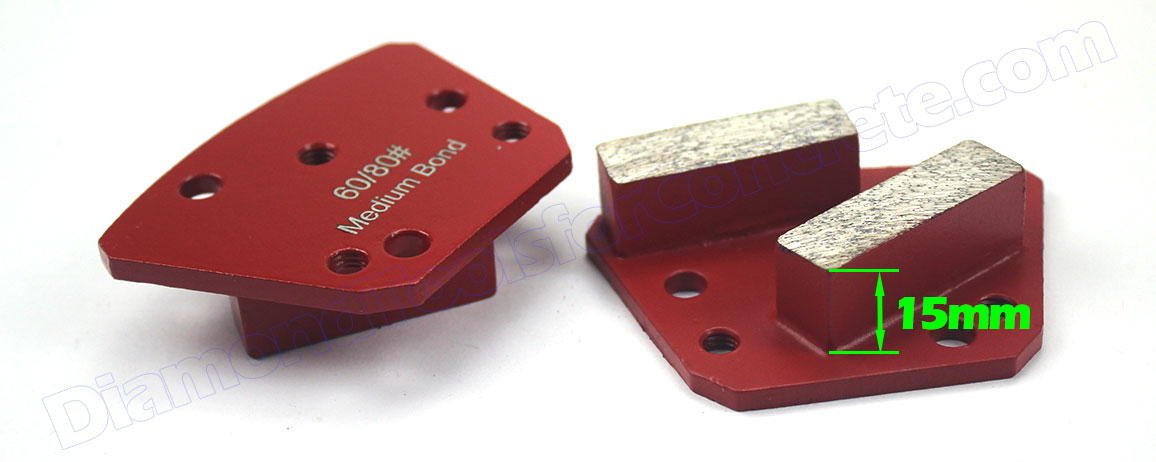

10mm Segment Height ASL Shoes

15mm Segment Height Blastrac Shoes

Despite different shapes (like bar, arrow, and button), the concrete grinding segments are also different in height. The supplier may not tell you the size, especially the height of the segments, but it matters. If the standard segment height of the factory is 10mm, would you like to make it higher to 12mm, 13mm, or 15mm?

In this article, we are going to discuss the influence of higher concrete grinding segment heights.

The reason to customize segment height

As a professional floor grinding shoes manufacturer in China, we have our standard segment size for different shapes of concrete grinding segments. Most of the segments are 10mm in height, but also some shapes have other standards: Like the hexagon segment is 12mm, and the oval segment is 13mm.

In past years, we have customized different segment heights for our customers, including 12mm, 13mm, 15mm.

Generally, many customers more care about the grinding performance, instead of the segment height. As a functioning part of the floor grinding diamonds, the segment height not only affects the lifespan but also has other benefits like creating product differentiation and saving shipping costs. Let’s figure it out.

There are mainly 3 reasons why they want to customize a higher segment height.

- First – creating product differentiation to make their tools special and increase sales.

- Second – increasing the lifespan of the diamond grinding tools.

- Third – saving the shipping cost.

Creating product differentiation

Product differentiation is the key aspect(s) distinguishing one company’s products or services from its competition. Successful product differentiation leads to brand loyalty and an increase in sales.

– Carol M. Kopp at Investopedia

If you are a reseller and want to beat your competitors, you need to make changes to your tools and make them more impressive than general products in the market. Except for the segment shape, the segment layout, the painting colors, and the paintings, one of the other aspects you can do is to use a different segment height.

Like what they did in the phone industry, there are different sizes of power capacity. The bigger the capacity, the longer the Standby Time, and the higher the price. It’s not only a strategy to increase the selling but also gives people more options. People can understand the differences and choose the one they want. It’s a win-win choice, so it is on the concrete grinding segments.

Longer lifespan of concrete grinding segments

Regularly, we measure the lifespan of concrete grinding segments by the square meters each millimeter segment can grind. So, since your segment height is higher than that of the same tools from other suppliers, if the quality is the same, your lifespan is surely longer than others. It’s reasonable for your segments to have a higher price.

If you offer a reasonable price on the higher grinding segments, your customers will remember that your tools have a longer duration. Then they are easier to become your regular customers.

Here is feedback from one of our customers for your reference. He is a contractor providing concrete grinding & polishing services:

The lifespan of 12mm segment bar

| Product Name | 2 bars Lavina concrete grinding segments with 16 grits |

|---|---|

| Application | For grinding concrete floor |

| Segment Size | 40x12x12mm |

| Diamond Grits | 16# |

| Quantity Used | 9pcs |

| Productivity | About 1000m2 |

| Lifespan of Each Tools | 1000÷9=111m2 |

| Lifespan of Each mm segment | 111÷24=4.63m3 |

Above is just an individual case. However, we can confidently state that you can grind the concrete floor with 9 pieces of our 2-bar floor grinding shoes for 600-900 square meters.

Saving the shipping cost

Have you ever thought that the higher segments can save the shipping cost? It really does. Let’s figure out how it works.

We assume there are 2 concrete grinding diamonds only in the difference of the segment height. Therefore, to achieve equal productivity, there will be differences in the quantity required for these two types of tools. Fewer tools with higher segments will be needed, while more tools with lower segment heights will be required.

To better understand, let’s make a comparison between 2 different heights of Lavina concrete grinding segments as an example.

Calculation for the saving on shipping costs

| Segment Type | 2 bars Lavina grinding diamonds | 2 bars Lavina grinding diamonds |

|---|---|---|

| Segment Size | 40x12x10mm(10mm height) | 40x12x15mm(15mm height) |

| Supposed Quantity | 12 pcs | 8 pcs |

| Same Total Segment Height, Same Productivity | 10mmx2x12=240mm | 15mmx2x8=240mm |

| Quantity Difference | 12pcs-8pcs=4pcs | |

| Estimated Net Weight of Each Lavina Blank Core | 0.2kg | |

| Total Weight Difference | 0.2kgx4=0.8kg | |

| Estimated Shipping Rate | 10 USD per kg | |

| Shipping Cost Difference | 0.8×10=8 USD | |

| Saved Shipping Cost of 15mm Lavina Grinding Shoes | 8USD÷8pcs=1 USD/pc | |

So, choosing 15mm segment height can save 1 USD on each Lavina grinding diamonds than 10mm height.

If you are a concrete grinding contractor importing concrete grinding diamonds from China, what would be the annual quantity of Lavina floor grinding shoes consumed? You can easily calculate this based on last year’s data. For instance, if you consume 100 pieces, choosing a 15mm segment height rather than 10mm could potentially save you an estimated $100 USD on shipping costs.

Conclusion

There are mainly 3 advantages of higher grinding segments. If you are a reseller, you may make your concrete grinding diamond tooling unique and increase sales. If you are a contractor or an end-user, you can have the benefit of saving shipping costs.

Although there are some benefits of higher concrete grinding segments, higher is not always better. You should find the balance between the grinding segment height and the price level, to meet the requirements of your target market.

Xpert Diamond Tools has full experience in making customized orders. Our OEM/ODM services span the entire production process, including the segment height we discussed here and many others.

Feel free to drop us a message using the form below, and you’ll get your unique concrete grinding diamond tooling!