9 Steps for Making Diamond Segments You Should Know

May 3, 2024

3 Benefits of Higher Concrete Grinding Segments

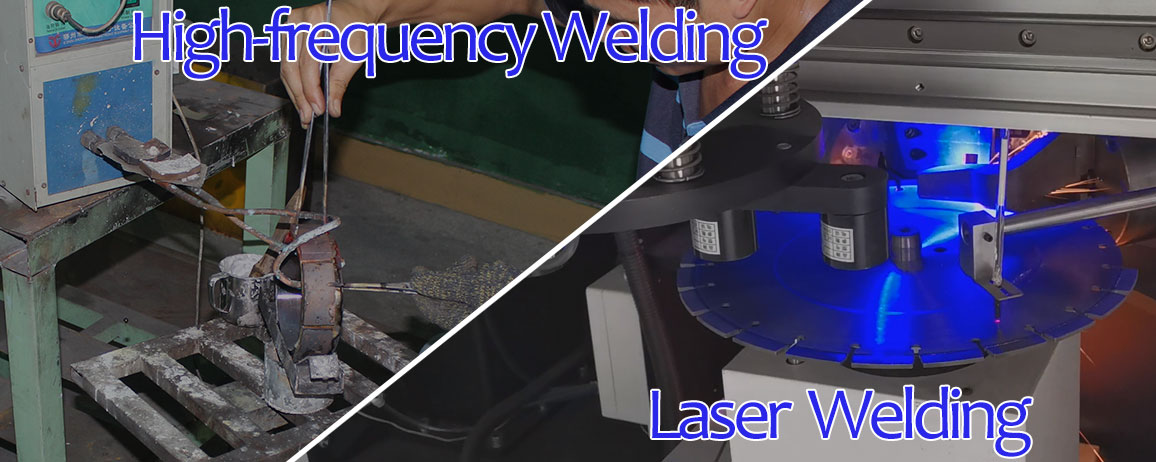

May 18, 2024When buying diamond tools like diamond saw blades, you may have seen that some of them are high-frequency welded and some of them are laser welded. But, what’s the difference between these 2 different welding methods? Which type should I choose? What’s the difference between these 2 different diamond tools welding machines? Continue reading and things will become clear.

Diamond tools come in diamond segments and blank cores, with different connection types like sintering and welding. But in this post, we are going to talk about welding only, especially to make a comparison between high-frequency welding and laser welding.

Table of Contents

High-frequency(HF) welding

High-frequency(HF) welding, also known as dielectric welding or radio-frequency(RF) welding, is a general technology for welding diamond tools. It is a technique that uses high-frequency electric currents to heat the surface of metals for welding, with the help of solders like copper and silver. This welding type is widely used in the diamond tools industry, because high-frequency welding strength is enough for general cutting/grinding/drilling of main materials like granite, marble, concrete, and other stones.

HF welding machine

HF welding machine comes with two pieces of equipment: one is the welding frame, and the other is the high-frequency power source. They work together to weld various types of diamond tools. The power source provides the heating, and the frame provides a workspace to fix the diamond tools and perform the welding.

High-frequency welding machine for diamond blades

Let’s take the diamond blade welding machine as an example. The diamond blade welding machine can be fully automatic or semi-automatic, but the semi-automatic type is more commonly used. In some ways, using the semi-automatic HF welding machine may be more reliable. The fully automatic type operates according to a set program and cannot adjust itself if it encounters any issues, whereas the semi-automatic type involves workers in the operation who can readjust. Additionally, the price of a semi-automatic HF welding machine is also much lower.

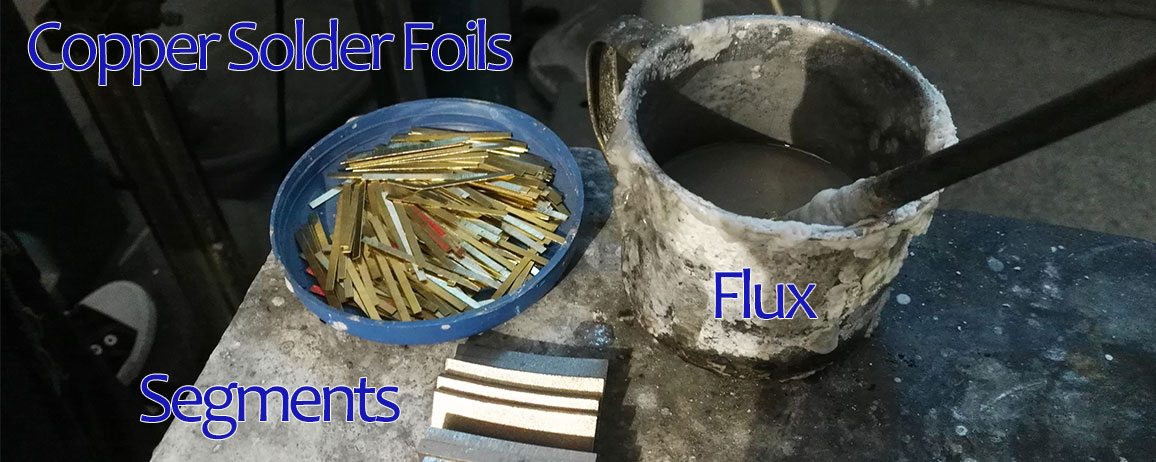

Copper(Cu) solder and silver(Ag) solder

As we said above, 2 solders are commonly used: copper and silver. So there are 2 different types of high-frequency welding. When the welding uses copper solder, it is called copper soldering, if silver, it is called silver soldering.

Copper solder foils and silver solder rods

Copper soldering is widely used for the general welding of various diamond tools, including diamond saw blades, concrete grinding diamonds, and diamond core drill bits. The melting point of solder depends on flux composition and formulation, but the melting point of copper solder is higher than that of silver type. Generally, copper solder melts at about 850°C-950°C and silver solder at around 600°C-800°C.

Copper solder has a higher welding strength than silver solder, but in some situations, we have to use silver solder, such as when welding marble segments and PCDs. Let’s take PCD welding for example. If we use copper solder, the welding temperature will be too high, and cause graphitization of the diamond layer, subsequently affecting the surface quality of PCD tools and reducing their lifespan. Therefore, it is recommended to use low-temperature silver(Ag) solder for welding PCD tools.

Solder fluxes

Solder flux is a chemical substance used in soldering to clean and prepare the surfaces to be soldered, promote the flow of solder, and prevent oxidation during the soldering process. It typically comes in liquid or paste form and is applied to the joint area before soldering.

Copper solder foils, solder flux and diamond segments

Flux can remove oxides from the welding surface and prevent it from oxidizing during heating, helping the solder to wet better. There are two different common shapes of the solder: sheets and rods. The sheet type is more commonly used for welding diamond tools and we usually cut it into small pieces and soak them into the corresponding solder fluxes, preparing for welding.

Diamond Tools laser welding

Laser welding is a welding technique that uses a highly focused beam of light, typically generated by a laser, to join materials together. It is usually used for welding diamond blades and diamond core drill bits, to cut hard materials like granite, concrete, and reinforced concrete and sticky materials like asphalt.

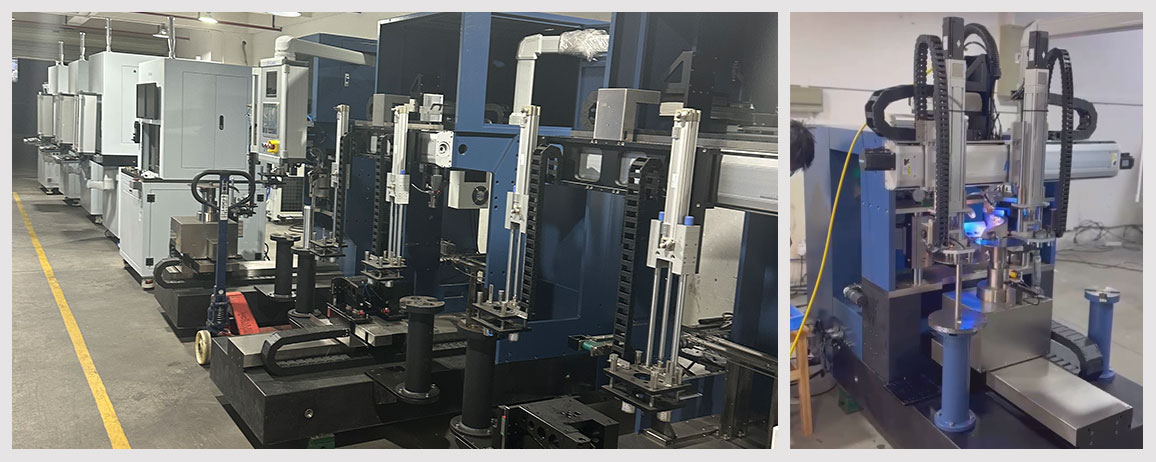

Laser welding machine

Different diamond tools need different welding strengths. Generally, the cutting and drill tools require higher welding strength than grinding tools. So laser welding machine is mostly used in automatically welding diamond blades and diamond core drill bits. While most are used for welding these two diamond tools separately, some are combined to weld these two different diamond tools in one machine.

Laser welding machine for diamond blades

If you have requirements to weld both diamond blades and diamond core drill bits, with a medium quantity, perhaps the combined machine is a choice. However, a separate machine might be a better choice. Because the combined machine can only weld one type at a time and you need to switch the function back and forth, which is a waste of time.

Advantages of laser welding

Compared with high-frequency welding, laser welding doesn’t need any solders, but the segments and blank cores are specially designed. If you want to buy segments or blank cores(like the blank blades), you should tell the supplier the welding type, so that they can supply you with the right products.

Laser welding has the following advantages:

- Strength: laser welding has a stronger welding strength than high-frequency welding, so it is more used for cutting/drilling hard materials like concrete and reinforced concrete.

- Precision: Laser beams can be focused on very small spots, allowing for precise control over the welding process.

- Speed: Laser welding is typically faster than high-frequency welding, as the laser beam can rapidly heat and fuse materials directly without any solders and fluxes.

- Automation: Laser welding can be easily integrated into automated manufacturing processes, increasing efficiency and reducing labor costs.

Xpert Diamond Tools uses Airx diamond segments and laser welding on our reinforced concrete cutting blades and reinforced concrete core drill bits, to increase cutting speed and maintain stable performance.

Conclusion

High-frequency welding and laser welding are 2 totally different welding methods. They are applied in different diamond tooling. High-frequency welding is more widely used in common diamond tools, but laser welding is used in diamond tools for tough jobs, like cutting/drilling reinforced concrete.

Comparison Between High-frequency Welding and Laser Welding

| High-frequency Welding | Laser Welding | |

|---|---|---|

| Applied Materials | Widely used for cutting/grinding/drilling granite, marble, stones, and other general construction materials. | Specialized in cutting/drilling hard materials like granite, asphalt, concrete, and reinforced concrete. |

| Automation | Fully automatic or semi-automatic | Fully automatic |

| Diameter arailable | It can weld large diamond blades, like 3000mm. | Generally, it is designed to weld diamond blades under 1200mm in diameter. |

| Price of the welding machine | More competitive | Very high |

| Requirements of Segments and Blank Cores | Normal segments and blank cores | Special segments and blank cores for laser welding |

| Welding Strength | High | Very high |

| Weld Seam | Wider and with some solder trace | Narrow and clean |

| Cutting Speed | Medium | Fast |

| Dry/Wet | Only for wet using | Can be used for dry cutting/drilling |

| Welding Price | Competitive | High |

In conclusion, when selecting diamond tools, your choice between high-frequency welded or laser welded should match both your budget and the demands of your project.

- If your project requires dry cutting/drilling, surely you should choose laser welding. But please also inform us of this requirement so we can provide the appropriate segment for dry using.

- If you aim to cut general concrete (with less or without reinforcing bars) and wish to save costs, opt for the high-frequency welded type.

- If you intend to cut hard materials like reinforced concrete, Arix + laser welding is highly recommended for its fast cutting speed and reliable performance.