Normal Core Bit Segments for Drilling Concrete

July 7, 2024

Roof Type Concrete Core Bit Segments for Retipping

July 10, 2024

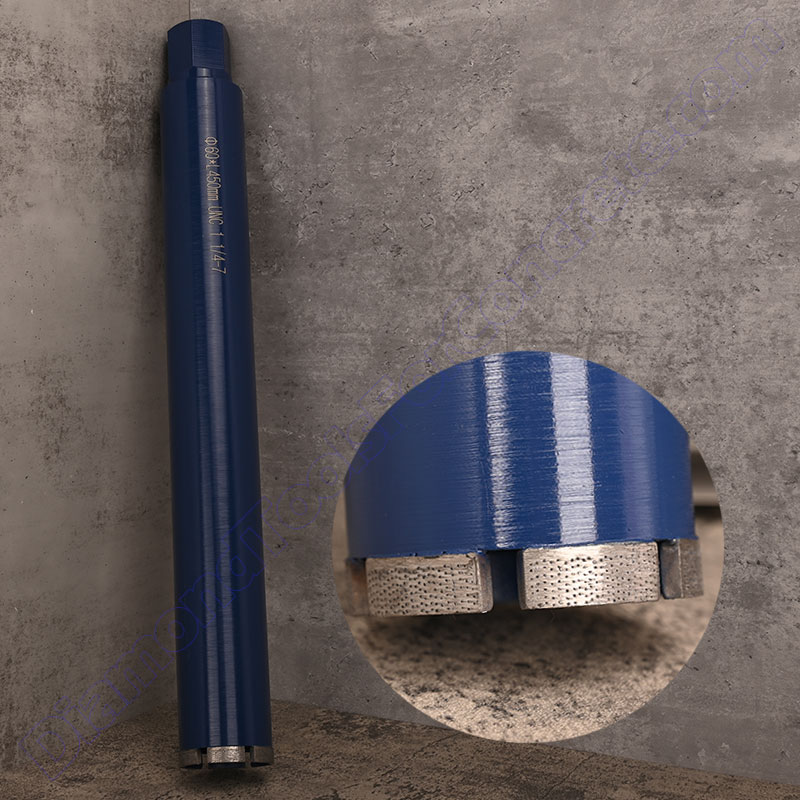

Arix Laser Welded Diamond Core Drill Bits for Reinforced Concrete

- Application

- Drilling concrete and reinforced concrete

- Core Bit Size

- D60*L450mm

- Connection

- 1 1/4-7 UNC

- Segment Type

- Arix

- Welding Type

- Laser welding

- Net Weight

- 1.8kg

- MOQ

- 5 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

Table of Contents

Product Features

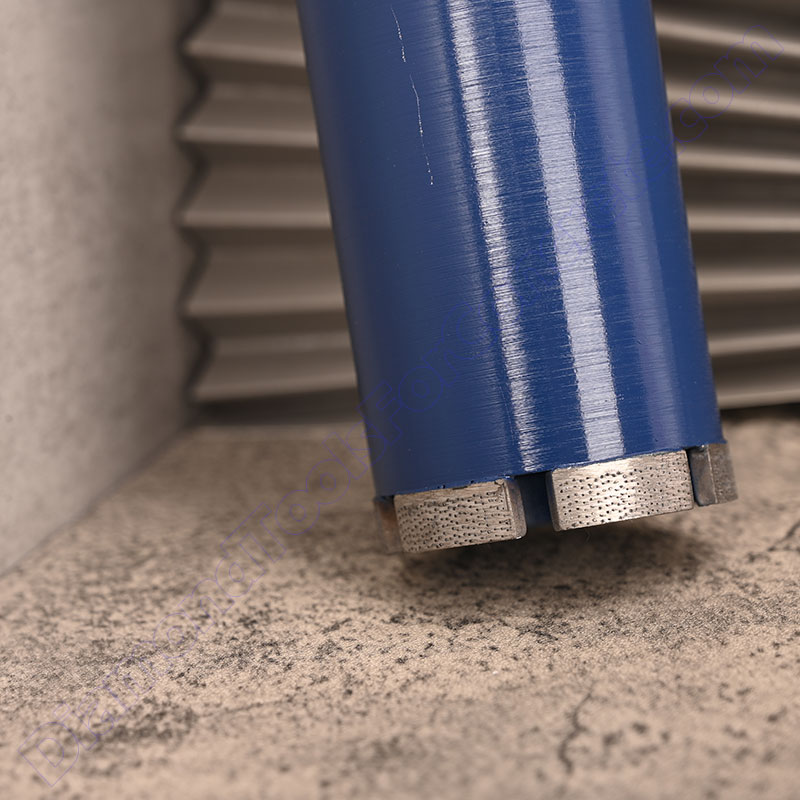

- Arix Technology: Combines Arix segments with laser welding for superior cutting speed and welding strength. It can be used for dry drilling.

- Efficient Drilling: Ideal for heavily reinforced concrete with high performance and durability.

- Cost and Time Savings: Reduces labor costs and speeds up project progress due to high efficiency.

- Customizable Sizes: Fully customizable core drill bits to meet specific project needs.

- OEM/ODM Support: Extensive experience in custom orders, including drawing, logo engraving, and color painting.

Description

The Arix diamond core drill bits usually work with laser welding for drilling heavily reinforced concrete. They are a perfect match: Arix segments provide the fastest cutting speed, and laser welding provides the highest welding strength.

Our Arix Laser Welded Diamond Core Drill Bits are specifically designed for efficient and durable concrete and reinforced concrete drilling. With excellent diamond formulas, these drill bits combine Arix technology with high-quality diamond particles to ensure outstanding drilling performance and long-term durability.

If the labor cost in your area is high, or you are on an urgent drilling project, these Arix diamond core drill bits should be a good choice because they perform with high efficiency and can speed up the progress of your project, saving labor costs.

As different projects need different sizes of diamond core drill bits, so the core drill bits are fully customized by our customers. As a professional diamond tools manufacture, we have a extend experience for OEM/ODM orders. If you want to customize the diamond core drill bits, we can give you a full support, including the drawing, logo engraving, color painting, etc.

As different projects require different sizes of diamond core drill bits, the core drill bits are fully customized by our customers. As a professional diamond tools manufacturer, we have extensive experience with OEM/ODM orders. If you want to customize the diamond core drill bits, we can provide full support, including drawings, logo engraving, color painting, etc.

Welding Types

We offer 2 different welding methods for our diamond core drill bit: high-frequency welding and laser welding. Laser welding enhanced the welding strength and is usually used the core drill bit for reinforced concrete. Because when cutting the rebar in the concrete, the segment will receive great force. High-frequency welding is usually used for the core drill bit for concrete, lightly reinforced concrete, stones, brick and other construction materials.

If you want to know more about the difference between high-frequency welding and laser welding, please check this article for reference: 2 Diamond Tools Welding Methods: High-Frequency VS Laser.

3 specifications – diamond core drill bits

When buying concrete core drill bits, there are 3 things that you need to confirm: Diameter, Length, and Connection. Only after these 3 specifications are confirmed, can we make the right tools for you.

Diameter

Because the barrel has thickness, there are two diameters: the outside and the inside. However, when we refer to ‘the diameter,’ we typically mean the outside diameter.

Length

There are 3 parts to a core drill bit: segments, barrel body, and connection. Each of them has a length. Generally, the length we are referring to is the length of the barrel body. The connection and segment are not included.

Connection

Connection is also a very important specification. It’s the way to connect the core drill bits to your core drill machines. There are various types of connections for core drill bits; the most common type is the threaded connection, including 1 1/4 UNC, G 1/2″, M14, 5/8″-11, etc.

| Diameters | 60mm |

|---|---|

| Length | 450mm |

| Connection | 1 1/4 |

| Segment Types | Arix |

| Welding Types | Laser |

Related products

-

D65mm Short Diamond Core Bits for Concrete Drilling

- Application

- Drilling concrete and reinforced concrete

- Core Bit Size

- D65*L60mm

- Connection

- M14

- Segment Type

- Roof

- Welding Type

- Laser welding

- Net Weight

- 0.4kg

- MOQ

- 5 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

-

Aero Type Concrete Core Bit Segments for Retipping

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Aero

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments

-

D32mm Elongated Concrete Hole Drill Bits with Crown Segment

- Application

- Drilling concrete, and other hard materials

- Core Bit Size

- D32*L450mm

- Connection

- 1-1/4-7 UNC

- Segment Type

- Crown

- Welding Type

- High-frequency welding

- Net Weight

- 1.2kg

- MOQ

- 3 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

-

Turbo Type Diamond Core Bit Segments for Concrete

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Turbo

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments