120mm Tuck Point Grinder Blade with Side Teeth

September 20, 2024

150mm Tuck Point Saw Blade with Drop Segments

September 21, 2024125mm Tuckpointing Blade with 6.4mm Standard Width

- Application

- Tuckpointing concrete for various purposes such as cutting channels for installation, creating decorative grooves, concrete crack repair, etc.

- Diameter

- 125mm

- Segment Type

- Normal segments

- Segment Width

- 6.4mm

- Segment No.

- 19pcs(without 6 teeth on each side)

- Net Weight

- 0.3kg

- MOQ

- 5 pieces

- Lead Time

- 10-20 days

Buying Guide for Tuck Point Blades

Table of Contents

Product Features

- Mortar Removal: Ideal for clearing and replacing mortar joints

- Faster Cutting: Shorter segments and wider gaps enhance cutting speed

- Wet Use Benefits: Improves chip removal and cooling for longer blade life

- Thicker Design: Removes mortar faster than standard blades

- Versatile Compatibility: Suitable for both dry and wet use with angle grinders

- Bond Type Selection: Options for different concrete hardness levels

Description

Tuck point diamond blades are ideal for removing mortar from masonry joints and routing decorative joints in stonework. Builders and bricklayers will find these blades effective for clearing old, weak, cracked, or damaged mortar between bricks, as well as for replacing “head joints” or “bed joints.”

This 125mm tuckpointing blade features shorter segments and wider gaps between them, enabling faster cutting speeds and reduced power consumption. When used wet, it efficiently removes cutting chips and helps cool the blade, ultimately extending its lifespan.

Thanks to their thickness, diamond tuckpointing blades remove mortar faster than standard diamond blades. With a segment width of 6.4mm, they efficiently traverse joints in a single pass. Suitable for both dry and wet use, our tuck point blades are designed for angle grinders.

What are tuckpointing blades?

Tuck point blades, also called tuckpointing or tuck point grinder blades, are thicker diamond blades designed for removing mortar joints and routing masonry surfaces like concrete, bricks, stone, and pavers. Typically, they are about 6.4mm wide, which fits most common mortar joint widths. Known for their quick cutting ability and durability, these blades feature a heavy-duty steel core with diamond dust segments. They can be used with handheld angle grinders or tile saws and are available in sizes 4″, 4.5″, 5″, and 7″. For larger sizes suitable for demo or road saws, please reach out with your specifications.

Key Information for tuckpointing blades

Tuck point grinder blades are specialized tools for tuck-pointing concrete floors. Here are four key factors to consider when selecting a blade:

- Blade Diameter: The diameter is essential for ensuring compatibility with your cutting machine and determining the cutting depth needed for your project. Choose a size that matches your equipment and depth requirements.

- Segment Width: Segment width directly impacts cutting width, so it’s crucial to align it with your project’s needs and desired cutting depth.

- Bond Type: Selecting the appropriate bond type based on the concrete’s hardness is vital. Options include:

- Extremely Soft Bond: For extremely hard concrete

- Very Soft Bond: For very hard concrete

- Soft Bond: For hard concrete

- Medium Bond: For medium concrete

- Hard Bond: For soft concrete

- Very Hard Bond: For very soft concrete

- Side Teeth: Blades may come with side protective teeth, enhancing performance. While they can increase costs, they provide benefits such as improved durability and cleaner cuts by stabilizing the blade and reducing wobbling.

Considering these factors will help you find the ultimate tuck point grinder blade for your needs.

| Diameters | 125mm |

|---|---|

| Side Teeth | without Side Teeth |

| Segment Types | Normal |

| Welding Types | Laser |

Related products

-

Vacuum Brazed Diamond Wire for Concrete (Reinforced) Cutting

- Application

- Cutting concrete and reinforced concrete.

- Features

- Vauum brazed beads

- Lenth

- 3.4 meter

- Fix Type

- Rubber + Spring

- Bead Size

- 11.0mm

- Net Weight

- 0.35kg/meter

- MOQ

- 10 meters

- Lead Time

- 1-2 weeks

Buying Guide for Concrete Wire Saw

-

230mm Husqvarna Cut-n-Break Twin Blades for Concrete Cutting

- Application

- For cutting hard materials like concrete, reinforced concrete, hard granite, hard rock, etc.

- Features

- Deep cutting depth with Husqvarna K760 or K4000 cut-n-break cutters

- Welding Method

- Laser welding (include the central flange)

- Diameter

- 9″(230mm)

- Segment Type

- Wave segments

- Segment Size

- 40×2.8x11mm

- Segment No.

- 15pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

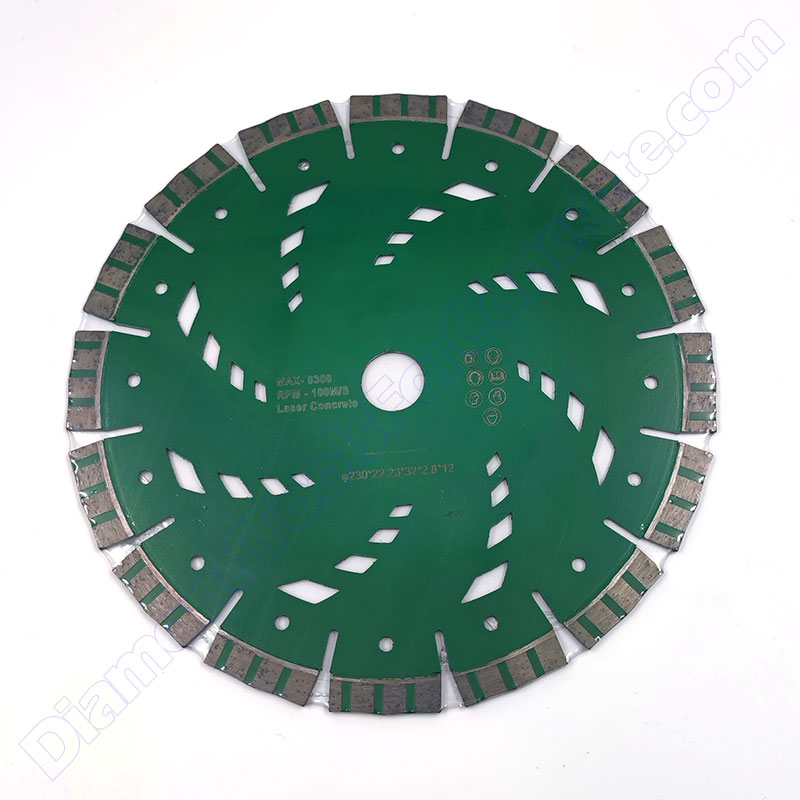

9 Inch Concrete Cutting Blade with Turbo Segments

- Application

- for cutting concrete and reinforced concrete

- Welding Method

- Laser welding

- Diameter

- 230mm

- Segment Type

- turbo segments

- Segment Size

- 32*2.8*12mm

- Segment No.

- 16pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

Reviews

There are no reviews yet.