Table of Contents

PCD floor grinding shoes are highly effective for a variety of floor coating removal applications due to their durability and cutting efficiency. Here are some common applications for these tools:

Removal of Epoxy Coatings

PCD tools are ideal for removing epoxy coatings from concrete surfaces. They efficiently strip away the tough, resinous layers without causing significant damage to the underlying concrete.

Eliminating Paint

These tools are perfect for removing multiple layers of paint from floors, especially in industrial and commercial settings where paint buildup can be thick and tough to remove.

Stripping Adhesive Residue

PCD tools can remove adhesive residues left from carpet, tile, or vinyl flooring installations, making the surface ready for a new application.

Tackling Mastics

Mastics, used in flooring installations, can be difficult to remove with traditional tools. PCD tools cut through these materials efficiently.

Removing Urethane and Polyaspartic Coatings

These high-performance coatings are used for their durability and resistance but can be challenging to remove. PCD tools handle these tough coatings effectively.

Eliminating Thinset and Mortar

PCD tools are excellent for removing thinset and mortar left behind after tile removal, ensuring a clean and smooth surface for the next installation.

Stripping Waterproof Membranes

These tools can remove waterproof membranes, which are often found in basements, balconies, and bathrooms, preparing the surface for new waterproofing or other treatments.

Surface Preparation

Beyond coating removal, PCD tools can be used to prepare surfaces by removing contaminants and roughening the concrete for better adhesion of new coatings or overlays.

5 things you may need to know

When buying PCD floor coating removal tools, there are five factors you may need to know to ensure you make the best choice for your specific needs.

1. What is PCD?

In the diamond tools industry, PCD stands for Polycrystalline Diamond. PCD is a synthetic diamond product that is made by fusing together diamond particles under high pressure and high temperature, creating an extremely hard and durable material.

Featured for their extreme hardness, durability, and thermal conductivity, PCD tools are highly effective at removing tough floor coatings like epoxy, paint, adhesives, and other materials. They are designed to provide aggressive cutting action, quickly and efficiently stripping coatings from concrete surfaces.

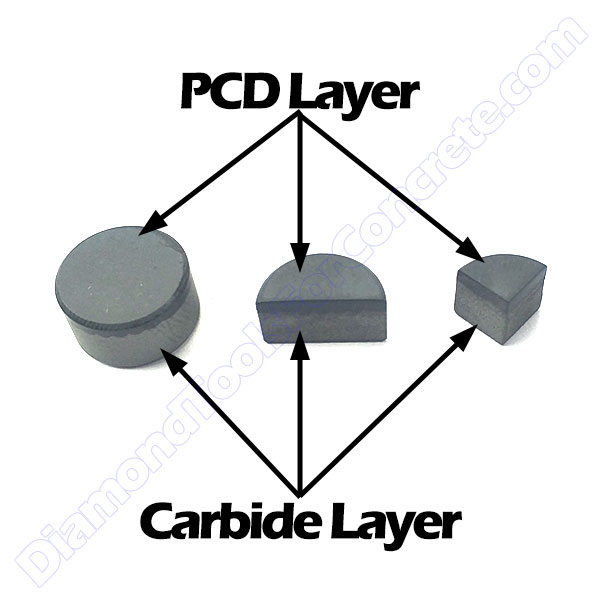

2. PCD structure & size

The PCD we use for floor coating removal is usually a button and has 2 layers: one thin layer of real PCD, and one thick layer of tungsten carbide. The layer of tungsten carbide in PCD tools offers essential support, bonding strength, shock absorption, thermal stability, and improved machining precision.

The commonly used sizes of PCD are full round, 1/2 round, 1/4 round, and 1/8 round. Different sizes provide different performances for removing floor coatings. Bigger PCDs are more aggressive and suited for heavy-duty removal, while smaller PCDs offer more precision and are better for lighter, more delicate tasks.

3. Reversed welding

Normal welding

Reversed welding

The reversed welding mainly occurs on the 1/4 PCD and 1/8 PCD. Let’s take the 1/4 PCD as an example. The first picture shows the normal welding for the 1/4 PCD on the HTC shoes. It can also be welded in the way shown in the second picture, which is called reversed welding.

4. PCD only or PCD combined with other materials

Except for PCD only, the PCD can also be combined with other materials to achieve different performance. The two materials are sacrificial segments and TCT (tungsten carbide teeth). The sacrificial segment can limit the cut depth of the PCD, preventing damage to the concrete, reducing aggressiveness, and making it suitable for removing medium to thin floor coatings like mastics, glues, epoxy, etc.

PCD only

PCD + sacrificial bar

PCD + sacrificial arrow

PCD + TCT(point shape)

PCD + TCT(rod shape)

What’s more, we also developed concrete grinding segments that were inserted with PCD. The shape of the inserted PCD can be irregularly crushed or regularly cut.

Segment bar inserted with regular PCD

PCD-crushed segment bar

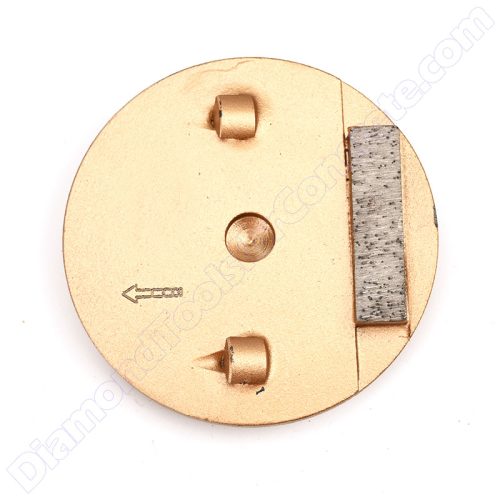

5. Direction of PCD shoes

Unlike segmented concrete grinding shoes, which don’t have an indicated rotation direction, PCD shoes do. After the welding of PCD is done, the direction of the PCD shoes is confirmed. Because the PCD has 2 layers, the rotation direction of the PCD shoes should utilize the PCD layer to remove the floor coatings, not the base layer of carbide.

All of the PCD shoes can be made in 2 different rotation directions, clockwise or anticlockwise. They are mirror-symmetrical. Different directions are designed to adapt to the rotation direction of the floor grinder. Don’t worry, when you place the order, we will confirm the direction of the PCD shoes with you.

PCD floor coating removal tools

PCD shoes are efficient for removing all kinds of floor coatings, including paint, glue, epoxy, mastic, adhesives, varnish, urethane, etc. To meet the requirements of different customers, Xpert Diamond Tools offers various PCD shoes for different floor grinding machines like HTC, Husqvarna, Lavina, Scanmaskin, ASL, Blastrac, and more.

HTC PCD floor coating removal shoes

The HTC blank plate is not thick enough to weld the PCD on it, so most of them are supplemented with an additional square plate to make it suitable for welding the PCDs. We have developed a series of PCD shoes for our customers, including PCD only, PCD plus sacrificial segments, PCD plus tungsten carbide teeth, and PCD inserted segments.

Full PCD + 1/4 PCD + bar

1/4 PCD

Full PCD + 1/2 PCD + segment

1/4 PCD + segment

PCD inserted segment

1/4 PCD + Carbide

1/4 PCD

1/4 PCD

Full PCD + 1/2 PCD + bar

1/4 PCD + bar

1/2 PCD + bar

1/8 PCD

Husqvarna PCD floor coating removal shoes

We provide 2 different types of PCD coating removal shoes for Husqvarna grinders: the round shape and the square shape. These are highly efficient for removing various floor coatings like paint, glue, varnish, epoxy, mastic, etc. The Redi-Lock quick change system allows for easy and fast tool changes.

1/4 PCD + bar

1/4 PCD + bar

1/4 PCD + bar

Full PCD

1/4 PCD + bar

Lavina PCD floor coating removal shoes

We developed a series of PCD shoes for Lavina floor grinders, including PCD only, PCD + sacrificial segments, PCD inserted segments, and PCD + tungsten carbide rods.

1/4 PCD

1/2 PCD

1/2 PCD + bar

1/2 PCD + button

PCD inserted segment

PCD inserted segment

1/4 PCD + carbide rod

1/8 PCD

Scanmaskin PCD floor coating removal shoes

For Scanmaskin PCD shoes, we offer different types, including trapezoid, round, and triangle. The Redi-Lock system allows for hassle-free tool changes. Ultra-sharp PCD segments ensure that these shoes can handle any challenging coating removal tasks, including thick and stubborn floor coatings.

1/2 PCD + bar

1/2 PCD

1/2 PCD + arrow

1/2 PCD

250mm(10″) PCD floor coating removal shoes

We provide different 250mm PCD concrete grinding wheels for floor coating removal. They fit floor grinders such as EDCO, Husqvarna, Blastrac, SPE, and MK.

- EDCO: MAGNA-TRAP 10″ Turbo Grinder;

- Husqvarna: Dual Trac RG 2112;

- Blastrac: BG-250, BG-250MKII, BGP-250, BGS-250-115, BGS-250-115-V2;

- SPE: DFG-250, DFG-280, DFG-400, DFG-500;

- MK: SDG-3, SDG-11, SDG-101, SDG103, DDG-5, DDG-11;

1/2 PCD + arrow

1/4 PCD + bar

PCD-crushed segment

1/4 PCD + carbide button

Trapezoid PCD floor coating removal shoes

We offer a wide range of trapezoidal PCD floor coating removal tools, including ASL, Blastrac, and other universal trapezoid shoes with 3 threaded holes.

1/4 PCD

Universal

1/4 PCD + bar

Universal

1/2 PCD + button

Universal

1/2 PCD + arrow

Universal

PCD-crushed segment

Universal

1/4 PCD + bar

Blastrac

1/2 PCD

Blastrac

PCD inserted segment

ASL

1/4 PCD + Carbide

ASL

Full PCD + 1/2 PCD + segment

Other PCD floor coating removal shoes

Below are several PCD tools designed for floor grinders, including Werkmaster, Syntec, PHX, Klinde, EDCO, and more.

1/2 PCD

Werkmaster

1/4 PCD + bar

Syntec

Full PCD

Floorex/Terrco

1/4 PCD

PHX

1/2 PCD + bar

PHX

1/4 PCD + arrow

Klindex

PCD-crushed segment

Frankfurt

1/4 PCD + arrow

Universal

1/4 PCD + bar

EDCO

Accessories

To make the concrete grinding diamonds compatible with different brands of floor grinders, we supply several adapters to ensure a perfect fit. 2 types of adapters are provided, one is for transfer metal/PCD shoes and the other is for using velcro diamond polishing pads.

What’s more, if you need the segments or PCD only, we can also supply them.

Adapters for metal/PCD shoes

Below are some adapters we’ve made to make metal/PCD shoes compatible with various floor grinders. With our extensive experience in OEM/ODM orders, we can also customize adapters to meet your specific needs.

HTC to Trapezoid

HTC to Husqvarna

HTC to Husqvarna

EDCO to Trapezoid

Klindex to Trapezoid

OEM service

We offer additional services for painting and laser engraving.

For end-users such as contractors, most do not require customized painting colors or logo engraving. In such cases, we proceed with standard painting and engraving procedures. However, most resellers seek to enhance brand visibility and recognition by customizing painting colors and engraving logos on tools.

Painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for Xpert Diamond Tools

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Laser engraving

Unlike metal bond concrete grinding diamonds, PCD shoes typically only display the logo and a directional arrow. The logo helps promote your brand and build your reputation in the market. The directional arrow indicates the correct rotation direction of the tools, ensuring the correct using.

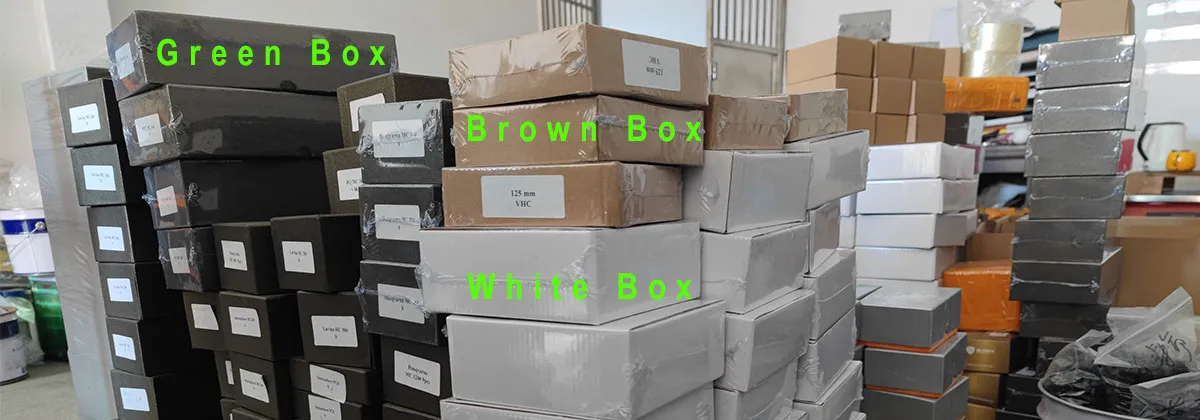

Packaging

In general, you needn’t worry about packaging arrangements as we handle it entirely on your behalf. When it comes to packaging, there are two primary considerations: box material and quantity per box.

Box materials

We offer three types of packing materials: the green hard box, the brown hard box and the white box. The green hard box is sturdier than the brown box, yet some customers prefer the brown option due to concerns about material wastage and environmental impact.

Quantity per box

Our metal bond concrete floor grinding diamonds are packaged in hard boxes containing 1pc, 3pcs, 6pcs, or 9pcs.

- The 1pc packaging is typically employed for large round-shaped concrete grinding discs, such as the 240mm Klindex grinding rings and 250mm EDCO floor grinding wheels.

- The 3pcs packaging is suitable for round grinding pucks.

- The 6pcs and 9pcs packaging options are versatile and can accommodate various types of concrete grinding diamonds, including Lavina, Husqvarna, HTC, Blastrac, and other types.

1 pc per box

One pc per box is used to pack diamond cup wheels or big concrete grinding wheels such as 250mm EDCO concrete floor grinding wheels.

3 pcs per box

3 pcs per box is used to pack concrete grinding pucks with 76mm or 83mm diameter. It may has a redi-lock, like Husqvarna diamond grinding pucks.

6 pcs per box

6 pcs per box is generally used to pack trapezoid and other normal floor grinding shoes, like ASL, HTC, Lavina, etc. This box is used the most and we recommend it.

9 pcs per box-A

This 9 pcs per box uses 9X1 layout and can be used to pack the normal floor grinding diamond segments like trapezoid, ASL, HTC, Lavina, Blastrac, Scanmaskin, etc.

9 pcs per box-B

This 9 pcs per box uses 3X3 layout and can be used to pack the normal floor grinding diamond segments like trapezoid, ASL, HTC, Lavina, Blastrac, Scanmaskin, etc.

Payment methods and terms

Regarding the payment process for concrete grinding diamonds, here are three key points:

- Currency: We accept payments in various currencies, including USD, EUR, RMB, and others.

- Payment Methods: Our supported payment methods include T/T (bank transfer) and Credit Cards.

- Payment Terms: For small orders, we require 100% payment in advance due to the relatively small amount. Splitting payments into multiple installments may incur additional bank fees. For large orders, we accept 70% payment in advance to initiate the order, with the remaining 30% balance due before shipment.

Furthermore, in support of our customers’ testing needs, we offer a 3% discount on sample (trial) orders. This discount will be reflected on the Proforma Invoice (PI).

Lead time

Lead time depends on various factors, primarily influenced by product type and order quantity. For PCD floor coating removal tools, we maintain a diverse inventory of different blank plates compatible with common floor grinding machines like HTC, Lavina, Husqvarna, Blastrac, and more. Consequently, orders for these commonly used tools can be expedited.

However, if you require customized tools or those not previously manufactured, initial production may take longer. Subsequent orders typically enjoy faster processing as we become more acquainted with your specifications.

Sample orders are typically shipped within 7-10 days. Regarding your orders, we strive for prompt delivery. But for your side, you need to plan a reasonable purchasing plan before your tools run/sell out, considering the production period and transportation time.

For urgent small orders, please contact us, and we can prioritize your tool production.

Anyway, we’ll provide an estimated lead time once your order details (including type and quantity) are confirmed.

Shipping methods

For delivery, there are five main shipping methods: Express, Air Freight, and Sea Freight are the most commonly used, while Rail and Truck are typically employed for destinations in Central Asia, Russia, Belarus, etc.

These shipping methods differ in various aspects. Let’s examine the main differences among Express, Air Freight, and Sea Freight.

| Express | Air Freight | Sea Freight | |

|---|---|---|---|

| Price | High | Medium | Low |

| Time | Fast | Medium | Slow |

| Suit Weight | Light weigh(such as the sample order) | Medium weight | Heavy weight |

| Method of Receiving Your Goods | Door-to-door | Pick up the goods yourself or Door-to-door service |

Pick up the goods yourself or Door-to-door service |

The shipping rates are tiered based on weight, with heavier shipments costing less per kilogram. If your order is close to qualifying for a lower rate by adding a bit more weight, we’ll notify you and confirm if you’d like to add more items to benefit from the better shipping rate.

Upon receipt of our proforma invoice, we will complete the shipping method, estimated transportation duration, and fees tailored to your specific order. In addition to reviewing the product items, kindly verify this section with us as well.