270mm HTC Bush Hammer Plate Case From Norway

June 7, 2024

Concrete Grinding Segments: 3 Factors to Affect the Price

June 12, 2024Table of Contents

Have you ever used a diamond saw blade or diamond core drill bit equipped with Arix diamond segments? If you have, congratulations! You must have already experienced the cutting speed brought by Arix technology, which is the cutting-edge technology in making diamond segments. Do you want to explore more about Arix segments? Why do they have better cutting performance? Let’s dive into it.

Brief introduction

The Arix diamond segment is the segment that uses Arix technology, which accurately places the diamond particles in a matrix form on each layer of the segment, to gain a consistent cutting force and maximize the cutting performance. It can be used on a diamond saw blade or diamond core drill bits for cutting/drilling hard materials, like hard concrete, heavily reinforced concrete, granite, hard rock, etc.

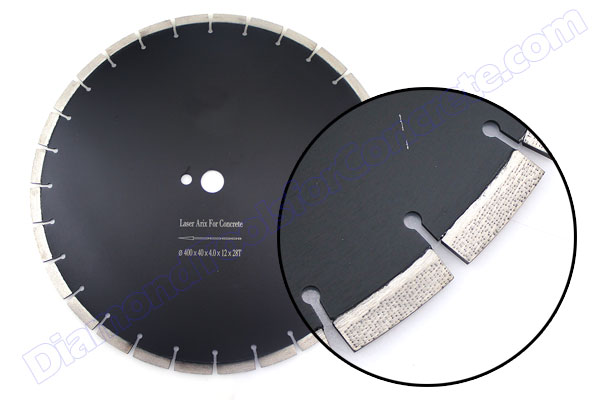

Concrete cutting blade with Arix segments

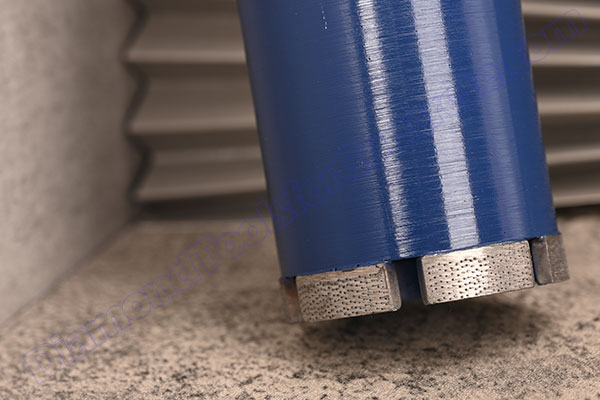

Concrete core drill bits with Arix segments

Arix technology

What is the Arix technology? Arix technology refers to a specific arrangement or technology used in the cold pressing of the diamond segments. Arix technology involves the precise placement of diamonds within the segment, often in a matrix that ensures optimal spacing and orientation. This leads to more efficient cutting and a longer lifespan for the segment.

Order arrangement

Diamond particles are precisely arranged in a specific matrix form on the blade, with each diamond in its predetermined position.

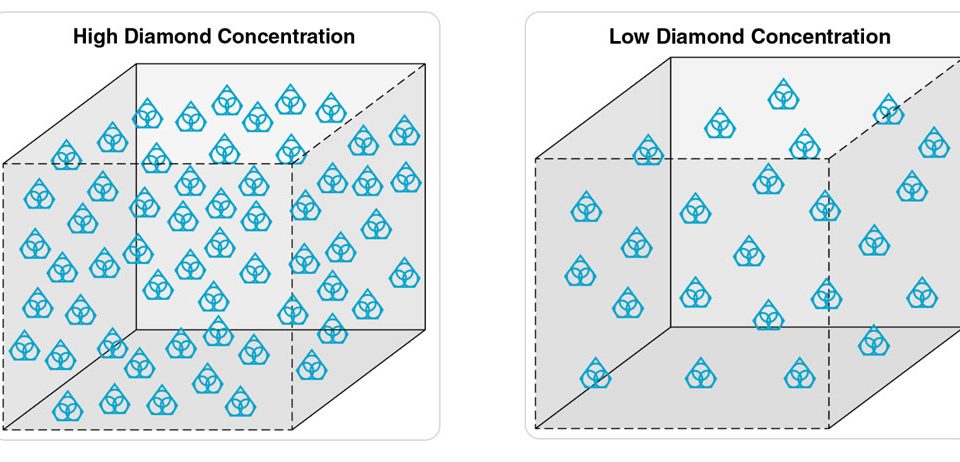

Uniform distribution

Ensures that each diamond particle is evenly distributed in each layer of the blade, providing consistent cutting force.

Precision manufacturing

Utilizes advanced manufacturing technology and equipment to ensure high precision and quality of the blade.

The process of cold pressing Arix segments

The theory behind the ARIX technology is not new and can be traced back to the 1930s, but it took a long time to bring this technology into diamond tools. In June 2003, the Shinhan Company in South Korea first succeeded in developing the automatic cold pressing machine for making ARIX diamond segments. Before that time, arraying the diamond particles orderly could only be achieved by using time-consuming manual labor—a situation which was clearly unacceptable for mass production.

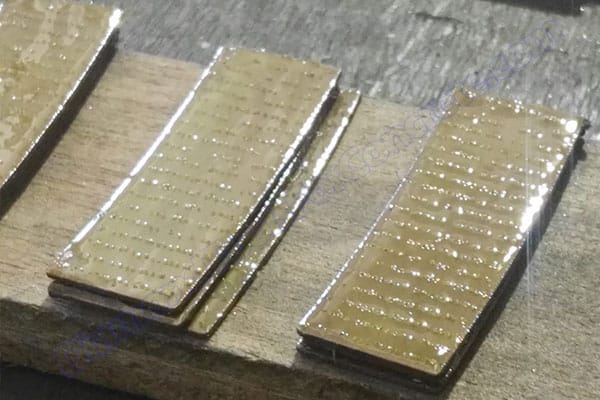

Automatic cold pressed Arix diamond segments

Manually arranged Arix diamond segments

After years of development, Chinese factories have now made a breakthrough and developed the cold pressing machine for Arix segments. Relying on a complete and mature supply chain, the China-made Arix cold pressing machines are more competitive and have already been exported to other countries, including Korea.

Differences in the cutting process

Conventional diamond segment

In conventional diamond segment manufacturing, the diamond particles are randomly distributed throughout the segment. As a result, each individual particle is not subjected to the same cutting force during the cutting operation.

Inside of the traditional segment

When particles are too closely clustered, the leading particles do most of the ‘work,’ while the following ones do not fully contribute to the cutting mechanism. This causes premature pullout of the leading particles. Conversely, when there are large gaps between particles, the bond is exposed to the workpiece, leading to erosion of the bond. The overall effect on blade performance is reduced tool life and slower cutting speeds.

Arix diamond segment

In Arix diamond segments, the diamond particles are evenly distributed throughout the bond. This ensures that all particles are subject to the same cutting forces, allowing the segment to operate at its optimum efficiency. The use of ARIX technology, which evenly distributes diamond grits within the metal powder of the bond, enables users to experience enhanced and uniform cutting efficiency.

Advantages of the Arix diamond segment

Arix diamond segments have greatly increased the cutting/drilling speed of diamond blades or core drill bits. Together with laser welding, they are especially great for cutting/drilling hard materials, such as concrete, reinforced concrete, hard granite, hard rock, etc. It’s good news for users in Western countries, where labor costs are very high. Below are some advantages of the Arix diamond segments:

- High Cutting Efficiency: The optimized arrangement of diamond particles allows Arix diamond segments to cut materials more efficiently.

- Longer Lifespan: The uniform wear distribution reduces excessive wear on individual particles, extending the blade’s lifespan.

- Stable Cutting Performance: Consistent cutting force provides more stable cutting performance, reducing the likelihood of issues during the cutting process.

- Reduced Heat Generation: The efficient cutting process minimizes heat generation, reducing the risk of thermal damage to both the blade and the material being cut.

- High-Quality Cutting: The orderly arrangement of diamond particles provides smoother and higher-quality cutting surfaces, particularly suitable for applications requiring high precision and surface quality.

- Versatility: Suitable for cutting a variety of materials, especially hard materials including concrete, hard stone, and other materials, making it widely used in construction, stone processing, and other industries.

Conclusion

A diamond saw blade or diamond core drill bit with both Arix segments and a laser welding method is the perfect solution for cutting or drilling heavily reinforced concrete(Dry use available). These tools provide much faster cutting speeds and stable cutting performance. If labor costs in your region are very high, Arix-segmented diamond tools are an excellent choice.

Nowadays, the development of cold pressing machines for Arix segments is growing very fast in China, and we are starting to export these machines to other countries. In the future, the business of Arix segments will become bigger and the prices will be more competitive, benefiting users worldwide.

Similar to other segments, Arix diamond segments also have different quality degrees, related to the quality of diamond particles and bonds. The customization of the Arix segments’ formula is available but requires a much larger minimum order quantity than normal segments. However, we believe it will become more customizable sooner or later.

Xpert Diamond Tools provides all kinds of Arix segmented diamond tools, including diamond saw blades and diamond core drill bits, for easily cutting concrete and reinforced concrete. We export our Arix segmented diamond tools worldwide, especially to Oceania countries like Australia and New Zealand, European countries like Norway, Ireland, Finland, Germany, Italy, France, the UK, and Belarus, and South American countries like Mexico and Bolivia. Around 800,000 pieces of Arix segments are used for laser welding annually by our laser welding machine.