U Segmented 14″ Ring Saw Blade for General Purposes

June 6, 2024

230mm Husqvarna Cut-n-Break Twin Blades for Concrete Cutting

June 9, 2024270mm HTC Bush Hammer Plate with 6 Carbide Rollers

- Application

- Aggressive grinding of floors for surface preparation or non-slip purposes

- Suitable Grinders

- HTC

- Diameter

- 270mm

- Carbide Roller

- D45mm*L32mm*30/45tips x 6 pcs

- Carbide Tip

- 4.7mm YG8 tungsten carbide tip

- Net Weight

- 8.7kg

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Bush Hammers

Table of Contents

Product Features

- Surface Preparation: Efficiently exposes aggregate, removes old coatings, roughens surfaces, and levels uneven joints.

- Infrastructure Use: Adds non-slip texture to roads, repairs, levels, and textures weathered surfaces.

- Architectural Texturing: Creates shot-blasted or “scabbled” surfaces with reliable grip.

- Specialized Design: 270mm HTC bush hammer plate with six carbide rollers, each with 30 or 45 high-quality tungsten carbide tips.

- Optimized Construction: Carbide rollers are inserted into the steel plate for a perfect fit with HTC floor grinders and come with replacement options.

- Durable Components: High-quality YG8 carbide tips and a dust-proof, efficient structure maximize tool output and longevity.

Description

Bush hammers are popular diamond tools used for texturing the surfaces of concrete, asphalt, or stone floors, enhancing their slip resistance, removing floor coatings for surface preparation, or making them more decorative. The functional part of a bush hammer can be carbide tips, vacuum brazed diamonds, or PCDs, allowing you to achieve the desired texture. Modern bush hammers simplify this process further by attaching to floor grinder machines, enabling you to select the preferred level of smoothness or roughness for the floor. Generally, there are three main purposes for bush hammering a floor:

Surface Preparation

- Pulverize the surface of concrete, making it fast and easy to achieve full aggregate exposure.

- Remove previous old coatings like paint, epoxy, etc.

- Roughen the surface for a new coating.

- Level uneven joints on concrete or other floors.

Infrastructure

- Add a non-slip texture to roads, pavements, and public areas.

- Repair, level, and texture weathered surfaces.

Architecture

- Produce surfaces appearing shot-blastes with reliable grip (“scabbled” surfaces)

Different types of bush hammers are designed to be used on different machines. This 270mm HTC bush hammer plate is designed for use on HTC floor grinding machines. It comes with six carbide rollers, and each roller has 30 or 45 pieces of 4.7mm tungsten carbide tips.

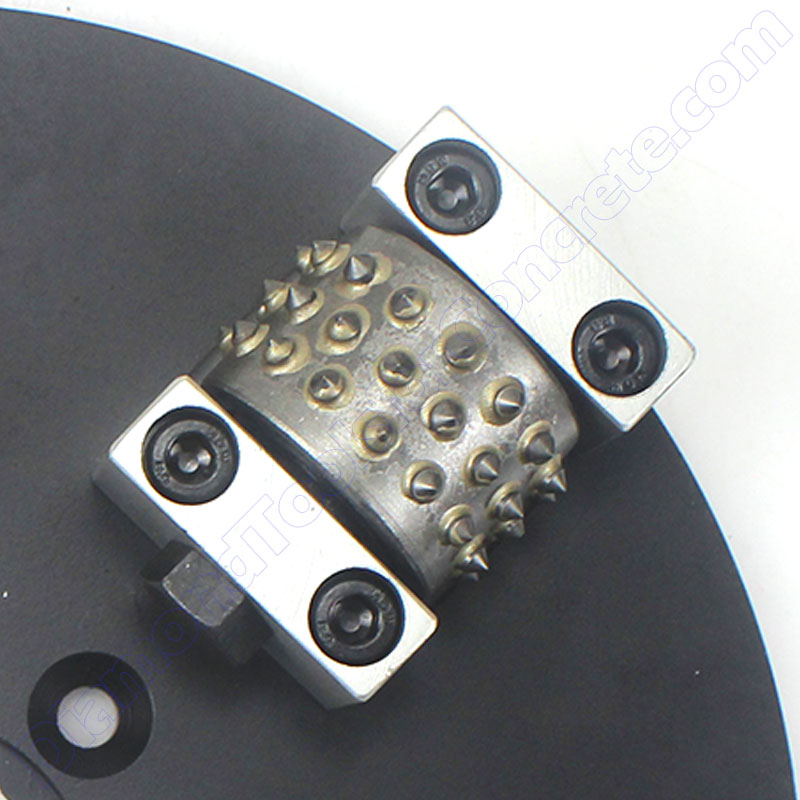

270mm HTC bush hammer plate with 30 tips per carbide roller

270mm HTC bush hammer plate with 45 tips per carbide roller

High-quality YG8 carbide tips are used to ensure the quality. The reasonable layout of the carbide tips maximizes the output of the bush hammer. The structure of this HTC bush hammer plate has been optimized: The carbide rollers are inserted into the steel plate, which makes the tools suit HTC floor grinders perfectly. To help the customer save costs, we also provide replacement accessories for the carbide rollers.

Carbide rollers inserted into the plate

Replacement carbide rollers

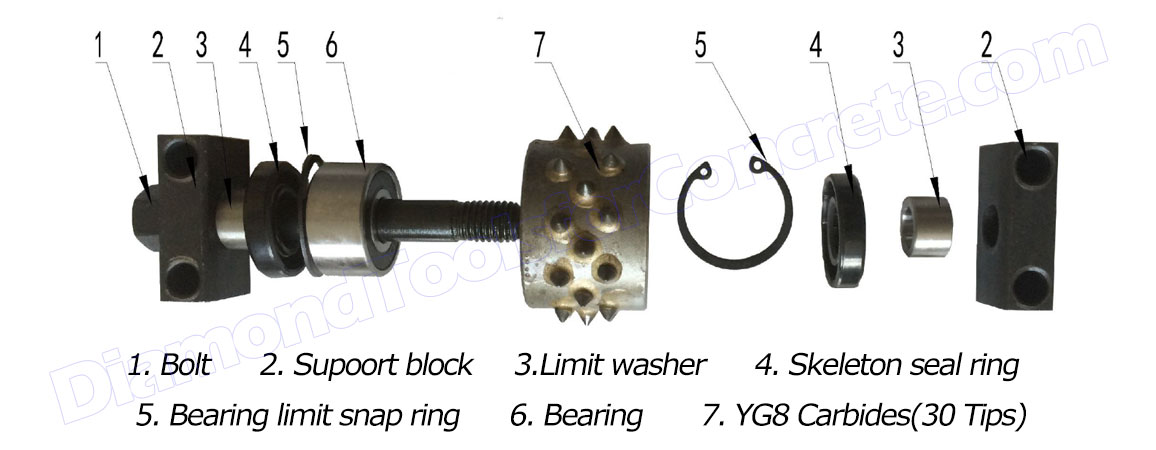

Structure of carbide roller

Our carbide roller consists of different parts such as bearings, seals, etc. We assemble these parts with a reasonable structure to maximize the output of the carbide roller, make it dust-proof, and lengthen its lifespan. Please check the structure of our carbide roller as follows:

Testimonial

| Suitable Grinders | HTC |

|---|---|

| Diameters | 270mm |

| Functional Part | Tungsten Carbide |

| Carbide Tips Per Roller | 30 Tips, 45 Tips |

Related products

-

2 Side-groove Husqvarna Redi Lock Segments for Concrete Grinding

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi lock adapters

- Diamond Segments

- 2 side-grooved segment bars

- Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- will update soon

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

2 Arrow Segments HTC Grinding Shoes for Concrete Floor

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- HTC, Husqvarna(EZ system)

- Diamond Segments

- 2 arrow segments(20x15x10mm)

- Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.18kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

Single Zigzag Husqvarna Diamond Grinding Segments for Concrete

- Application

- Surface preparation; Aggregate exposure; Glue & coating removals

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi-lock adapter

- Diamond Segments

- 1 zigzag segment;

36*5*12mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- will update soon

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

Reviews

There are no reviews yet.