76mm Assembled Wet Core Drill Bits for Concrete

October 3, 2024

125mm Double Layers Bush Hammer Plate for Angle Grinder

October 4, 2024

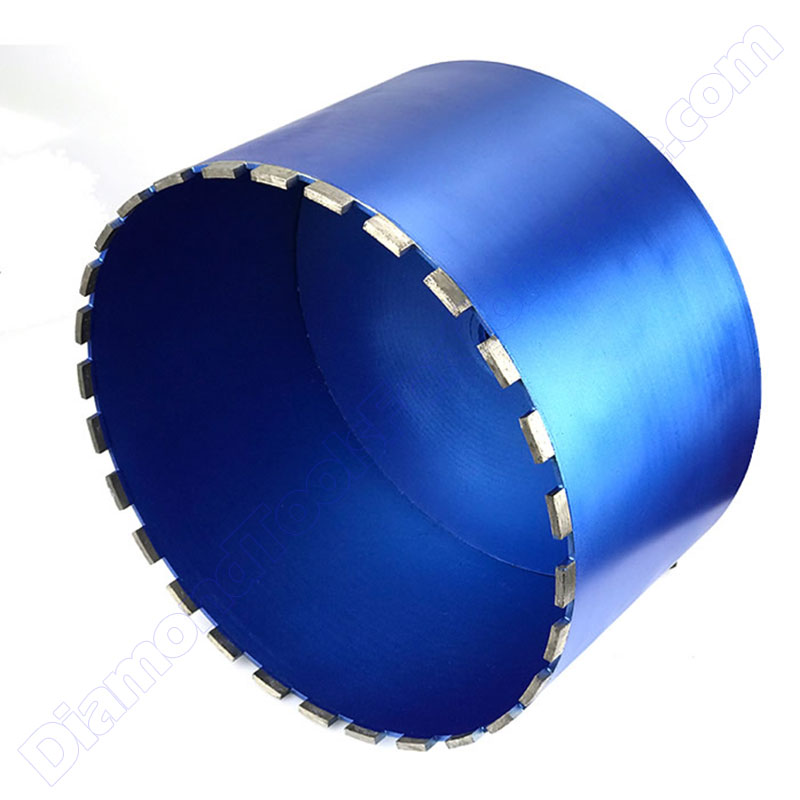

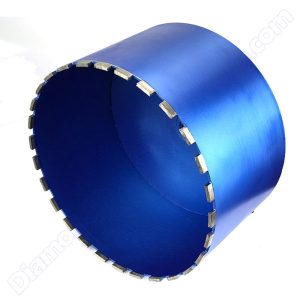

406mm Diamond Core Drill Bit for Concrete

- Application

- Drilling concrete, brick, and other hard materials

- Core Bit Size

- D406*L200mm

- Connection

- 1-1/4-7 UNC

- Segment Type

- Normal

- Welding Type

- High-frequency welding

- Net Weight

- Will update soon

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

Table of Contents

Product Features

- Versatile Applications: Ideal for creating openings for plumbing, electrical conduits, and large diameter anchor bolts.

- Construction and Infrastructure Use: Effectively handles significant material removal in thick concrete structures.

- High Customizability: Tailored to meet diverse customer requirements for size, connection method, welding technique, and application.

- Welding Options: Laser welding recommended for reinforced concrete and dry drilling; high-frequency welding available for ordinary concrete.

Description

This diamond core drill bit for concrete features a large diameter of 400mm and a short length of 200mm. Designed with standard segments for wet drilling, it is ideal for extracting large cores in applications such as creating openings for plumbing, electrical conduits, or large diameter anchor bolts. Commonly used in construction and infrastructure projects, this bit is particularly effective in areas requiring significant material removal or when working with thick concrete structures.

Diamond core drill bits are highly customizable products, as different customers have varied requirements regarding size, connection method, welding technique, and application. For drilling reinforced concrete or for dry drilling, we recommend laser welding for optimal performance. If your needs are limited to wet drilling of ordinary concrete, high-frequency welding may be a more cost-effective option. Additionally, we can tailor other aspects such as sizes, connection methods, and coatings to meet your specific requirements, ensuring you receive a diamond core drill bit for concrete that is best suited for your drilling project.

Welding Types

We provide two welding methods for our diamond core bits for concrete: high-frequency welding and laser welding. Laser welding offers superior strength, making it the ideal choice for core bits used on reinforced concrete, where segments face significant stress from cutting through rebar. In contrast, high-frequency welding is generally utilized for core bits designed for materials like concrete, lightly reinforced concrete, stone, brick, and other construction materials.

For more details on the differences between high-frequency welding and laser welding, please refer to our article: 2 Diamond Tools Welding Methods: High-Frequency VS Laser.

3 specifications

When purchasing concrete diamond core bits, it is essential to confirm three key specifications: diameter, length, and connection type. Once these are determined, we can manufacture a tool precisely tailored to your needs.

Diameter

Core bits feature two diameters due to the barrel’s thickness: the outside diameter and the inside diameter. However, the term “diameter” typically refers to the outside diameter.

Length

A core drill bit is composed of three main parts: the segments, barrel body, and connection. While each part has its own length, “length” usually pertains specifically to the barrel body, excluding the connection and segments.

Connection

The type of connection is another important specification, as it dictates how the core bit attaches to your drilling machine. The most common connection types are threaded, including options like 1 1/4″ UNC, G 1/2″, M14, and 5/8″-11.

Packaging – diamond core drill bit for concrete

We employ specialized packaging methods for our short and long diamond core drill bits to ensure they are well-protected during transit.

Short core bits are packed in a sturdy green hard box with foam cushioning for maximum impact protection. For longer core bits, we first wrap the body in a protective net to prevent scratches, then securely place it in a white box. This tailored packaging ensures that both types of drill bits arrive safely and in pristine condition, ready for immediate use.

Packaging of short diamond core bits

Packaging of long diamond core bits

Packaging of large diamond core bits

| Diameters | 406mm |

|---|---|

| Length | 200mm |

| Connection | 1 1/4 |

| Segment Types | Normal |

| Welding Types | High-frequency |

Related products

-

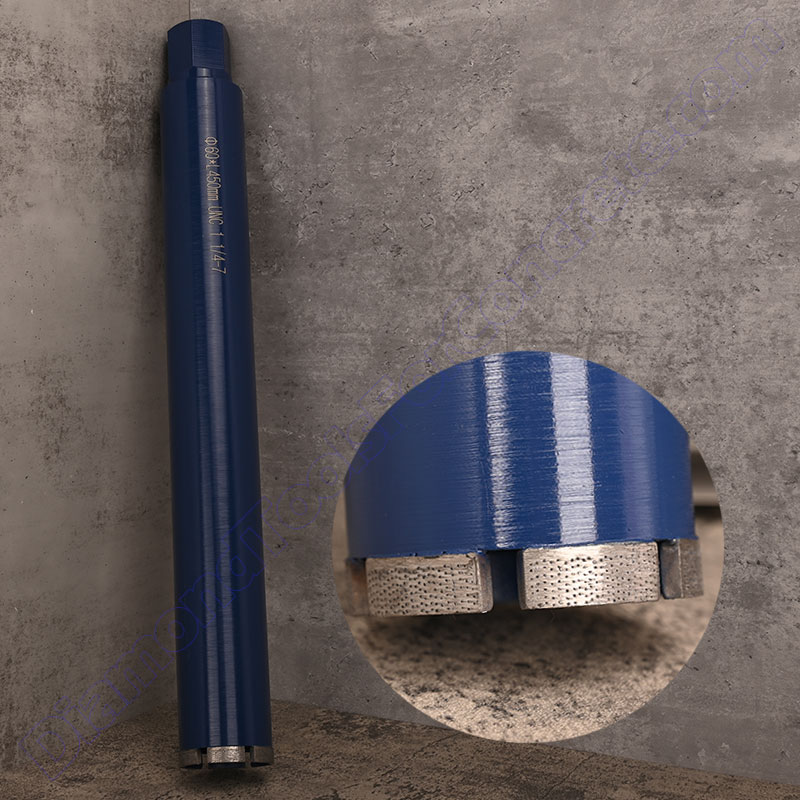

110mm Concrete Diamond Core Bit with Roof Segments

- Application

- Drilling concrete, brick and other materials

- Core Bit Size

- D110*L450mm

- Connection

- 1 1/4-7 UNC

- Segment Type

- Roof

- Welding Type

- High-frequency welding

- Net Weight

- 3.2kg

- MOQ

- 5 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

-

Arix Laser Welded Diamond Core Drill Bits for Reinforced Concrete

- Application

- Drilling concrete and reinforced concrete

- Core Bit Size

- D60*L450mm

- Connection

- 1 1/4-7 UNC

- Segment Type

- Arix

- Welding Type

- Laser welding

- Net Weight

- 1.8kg

- MOQ

- 5 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Drill Bits

-

Normal Core Bit Segments for Drilling Concrete

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Normal

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments

-

Turbo Type Diamond Core Bit Segments for Concrete

- Application

- Retipped on the barrel/tube for drilling concrete & reinforced concrete

- Segment Type

- Turbo

- Segment Size

- 11 different sizes for D32mm-D500mm barrels

- Net Weight

- 0.004-0.012kg

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Core Bit Segments