2 Octagon Segments Lavina Concrete Grinding Shoes

July 14, 2024

800mm Wall Cutting Blades with V-shape Segments

July 16, 2024

400mm Laser Asphalt Cutting Blade with 4 Drop Segments

- Application

- Cutting asphalt for road and pavement repairs, creating expansion joints, etc.

- Features

- With 4 drop segments

- Welding Method

- Laser welding

- Diameter

- 16″(400mm)

- Segment Type

- Normal segments

- Segment Size

- 40×3.8x12mm

- Segment No.

- 24pcs(4 drop segments)

- Net Weight

- 2.7kg

- MOQ

- 5 pieces

- Lead Time

- 10-20 days

Buying Guide for Asphalt Cutting Blade

Table of Contents

Product Features

- Cutting Efficiency: Designed for fast cutting of asphalt and effective with green concrete.

- Segment Height: Standard 12mm, customizable to 10mm or 15mm.

- U-Shaped Slots: Large U-shaped slots improve air circulation for better cooling and chip removal.

- Applications: Suitable for Crack Repairs, Expansion Joint Cutting, Airport Runway Maintenance, Sports Facilities Construction, and more.

- Drop Segments: Enhance performance and durability by reducing friction and improving cooling.

- Laser Welding: Provides a strong, durable bond between diamond segments and steel core, ensuring better performance and longevity.

Description

This 400mm (16-inch) asphalt cutting blade is equipped with 24 pieces of diamond segments, including 4 drop segments to enhance cutting performance. It is designed for fast cutting of asphalt and is also effective with green concrete. The segment height is 12mm, but can be customized to other heights like 10mm or 15mm. There are 2 center holes for connection, and we can accommodate other arbor hole requests as needed.

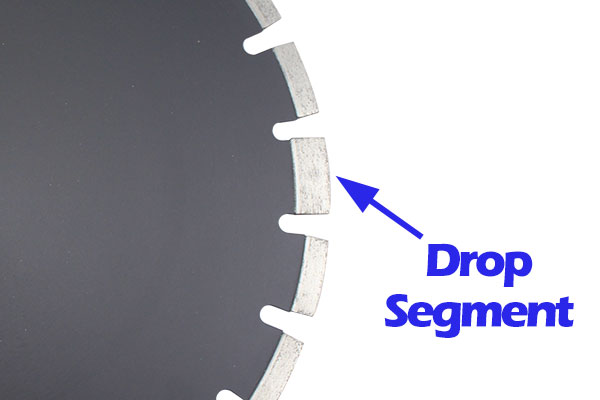

Drop segments

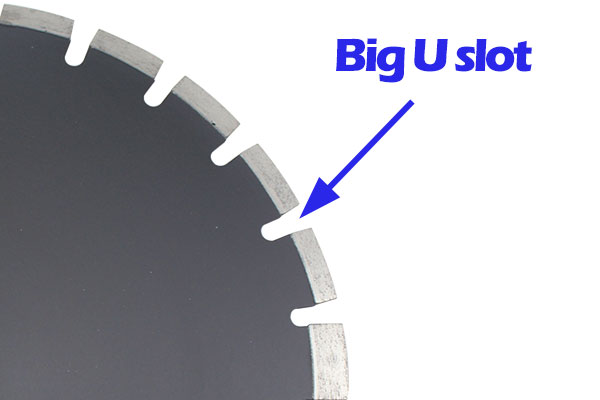

Big U slots

The large U-shaped slots on the blade are designed to significantly enhance air circulation, which effectively aids in cooling the blades during use. This improved cooling mechanism helps maintain the blade’s performance and longevity. Additionally, the U-shaped slots facilitate the efficient removal of cutting chips, ensuring a smoother and cleaner cutting process.

The asphalt cutting blade can be used for various applications, including Crack Repairs, Expansion Joint Cutting, Airport Runway Maintenance, Sports Facilities Construction, and more. Regardless of the project, Xpert Diamond Tools will find the best solution to fit your cutting machines and meet your requirements for asphalt-cutting projects.

Drop segments

The asphalt diamond cutting blade typically features several drop segments and laser welding methods.

Drop segments on the asphalt cutting blade are a critical design feature that significantly enhances the blade’s performance, safety, and durability, making it well-suited for the demanding task of cutting through asphalt. As asphalt becomes very sticky during cutting and increases in temperature, the drop segments reduce friction and improve cooling, thereby enhancing performance and durability.

Laser welding

Laser welding is used for asphalt cutting blades because it creates a strong, durable, and precise bond between the diamond segments and the steel core. This enhances the blade’s performance, safety, and longevity, making it well-suited to withstand the high-stress and high-heat conditions encountered during asphalt cutting.

Lifespan of asphalt cutting blade

The lifespan of an asphalt cutting blade is typically expressed by its cutting depth and cutting length. For example, our 350mm asphalt blade with a segment height of 10mm can cut over 1000 meters of grooves with a 10cm cutting depth. We provide three different quality levels (diamond formulas) to meet the requirements of customers in different areas. The diamond formulas can be optimized after customers test our asphalt-cutting diamond blades.

Packaging – 16 inch asphalt diamond blade

Packaging of Medium Size Diamond Saw Blade

The common diameter range of asphalt cutting blades typically spans from 300mm (12 inches) to 600mm (24 inches). Smaller blades, such as 300mm to 350mm (12-14 inches), are often used for handheld saws, while larger blades, like 500mm to 600mm (20-24 inches), are commonly used with walk-behind saws for cutting asphalt on roads and other large surfaces.

Due to the blade’s diameter, we typically pack the asphalt cutting blade in a white box, which is the second packaging method we use for concrete cutting blades. First, the diamond blades are shrink-wrapped in transparent plastic, and then the asphalt cutting blade is placed in a white box for added protection.

| Diameters | 400mm |

|---|---|

| Welding Types | Laser |

| Silent/Non-Silent | Non-Silent |

| Wet/Dry Cutting | Wet |

Related products

-

150mm Soff Cut Saw Blades for Early Entry Concrete Cutting

- Application

- for early entry cutting of green or uncured concrete

- Features

- soff cut triangular arbor

- Welding Method

- Laser welding

- Diameter

- 6″(150mm)

- Segment Type

- normal segments

- Segment Size

- 31×2.8x10mm

- Segment No.

- 12pcs

- Wet/Dry

- Dry

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

14″(350mm) Arix Ring Saw Blades for Reinforced Concrete

- Application

- Dry/wet cutting concrete & reinforced concrete

- Features

- Arix segments & laser welding (increase the cutting speed compared to normal segments)

- Diameter

- 14″(350mm)

- Segment Type

- Arix segments

- Segment Size

- 32×4.0x12mm

- Segment No.

- 22pcs

- Net Weight

- 1.0kg with driving wheel

- MOQ

- 1 pieces

- Lead Time

- 7-14 days

Buying Guide for Ring Saw Blades

-

Laser Welded 14 Inch Concrete Saw Blade

- Application

- for cutting concrete and reinforced concrete

- Welding Method

- Laser welding

- Diameter

- 350mm

- Segment Type

- normal segments

- Segment Size

- 40*3.2*10mm

- Segment No.

- 24pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

14 Inch Concrete Cutting Blade with Silent Core

- Application

- for cutting concrete and reinforced concrete

- Welding Method

- Laser welding

- Diameter

- 350mm

- Segment Type

- normal segments

- Segment Size

- 40*3.2*12mm

- Segment No.

- 24pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade