Vacuum Brazed Diamond Wire for Concrete (Reinforced) Cutting

July 16, 2024

7 Inch Concrete Grinding Wheel with 24 Turbo Segments

July 18, 2024

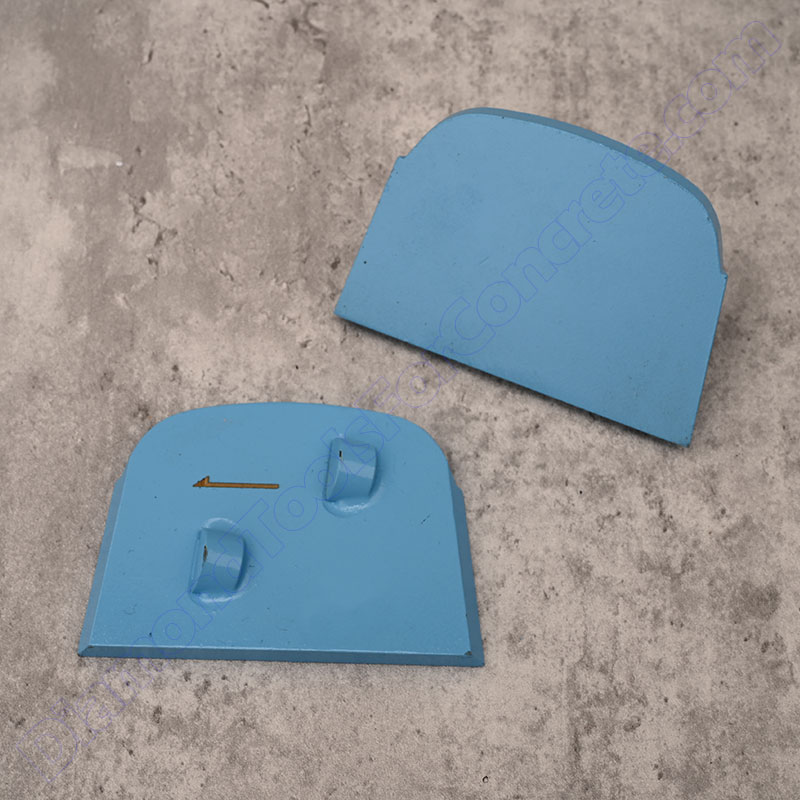

2 Half-round Lavina PCD for Floor Coating Removals

- Application

- Aggressive floor coating removal of mastic, glue, epoxy, and other stubborn coatings.

- Suitable Grinders

- Lavina and other grinders with adapters

- PCD

- 2 half-round PCDs

- Net Weight

- 0.18kg

- MOQ

- 12 pieces

- Lead Time

- 1-2 weeks

Buying Guide for PCD Coating Removal Tools

Table of Contents

Product Features

- Efficient Coating Removal: Lavina PCD features two half-round segments designed for effective removal of various floor coatings, including thick mastics, glue, elastomeric membranes, and epoxy coatings 30 mils thick or more.

- Aggressive Performance: PCD tools are significantly more aggressive compared to metal bond concrete grinding diamonds, making them ideal for tackling very thick and stubborn coatings with greater ease.

- Directional Considerations: Unlike metal bond diamonds, PCD tools rely on the edge for coating removal, making directionality important for effective use.

Description

This Lavina PCD is equipped with two half-round PCD segments, designed for efficient removal of various floor coatings, including thick mastics, glue, elastomeric membranes, and epoxy coatings 30 mils thick or more. Compared to metal bond concrete grinding diamonds, PCD tools are significantly more aggressive and capable of tackling very thick and stubborn coatings with greater ease.

6 types of coating removal tools

There are six main types of diamond tooling used for floor coating removal, listed below from left to right in increasing order of aggressiveness. Metal bond segments are the least aggressive, while PCD tools are the most aggressive. Additionally, bush hammer tools can also be effective for removing floor coatings in certain situations, such as line marking removal.

Metal bond segments only

Certain segment shapes, like arrow and zigzag segments, are suitable for removing thin floor coatings. These shapes typically leave fewer scratches compared to PCD segments.

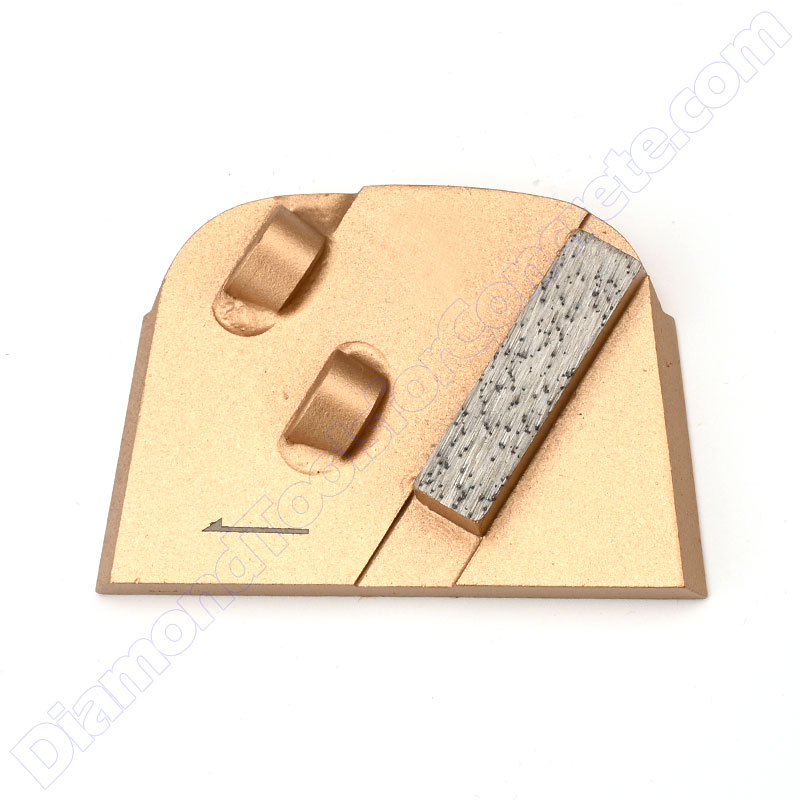

PCD mixed segments

These PCD mixed segment bars create a powerful tool for removing adhesives, sealants, and coatings from smooth or troweled surfaces without damaging the concrete.

Crushed PCD mixed segments

The crushed PCD fragments appear irregular. They are crushed or randomly broken into larger pieces, giving a more aggressive cutting or grinding action, especially on tough materials.

PCD + sacrificial segments

The sacrificial segments control the cutting depth of the PCD, reducing its aggressiveness and preventing damage to the concrete floor. This tool is well-suited for removing medium to thin mastics, glues, and failing epoxy coatings.

PCD + TCT(Tungsten Carbide Teeth)

Tungsten carbide teeth are commonly used in bush hammer tools. Although not as hard as PCD, tungsten carbide teeth can assist PCD in the removal of floor coatings.

PCD only

Among these six types, PCD is the most aggressive. It is used for removing thick floor coatings such as mastic, glue, and epoxy, and it leaves a coarse profile on the underlying concrete.

PCD directions

Generally, we don’t need to worry about the direction of metal bond concrete grinding diamonds, but for PCD floor coating removal diamonds, we need to care about it. Because different from the concrete grinding segments, the PCD doesn’t have a flat area for grinding, but it relies on the edge of the PCD for removing the coatings.

2 different directions of HTC PCD tools

Clockwise direction

Anticlockwise direction

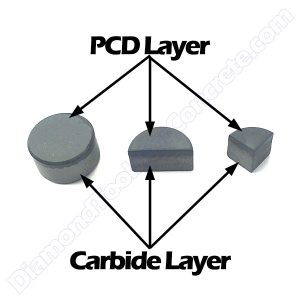

When grinding, the PCD layer will work first and then the tungsten carbide layer will work as behind.

There are 2 reasons that why PCD floor coating removal diamonds have a direction.

The structure of PCD

PCD is the abbreviation of Polycrystalline Diamond. It has 2 layers, one is the tungsten carbide and the other is actually the PCD layer. Please check the photos below.

What we need to do is use the PCD layer to remove the coatings, correct? Therefore, the key is to align in a direction that allows us to use the PCD layer effectively. However, since we’ll be painting colors over the surface of the PCD tools and thus obscuring the PCD layers, we need an alternative method to identify the correct direction.

PCD welding

To securely weld the PCDs onto the steel base, we need to create grooves in the steel base to properly position the PCDs. During the welding process, the PCDs will be tilted in one direction to maintain a specific angle. Consequently, there is only one correct rotation direction that aligns with the orientation of the steel base.

We will print an arrow on the tools to indicate the right rotation direction.

Optional painting colors

Our standard colors for PCD floor coating removal diamonds are yellow and gold. However, similar to concrete grinding diamonds, we can also customize the color to your preference.

Packaging methods – Lavina PCD

The packaging methods for Lavina PCDs are identical to those used for Lavina grinding diamonds.

Our Lavina concrete grinding segments are thoroughly protected and packed before shipping to prevent damage during transit. We use three types of hard boxes, each lined with pearl cotton: green, brown, and white. The green box offers the highest level of protection, while the brown and white boxes are more environmentally friendly.

6 pcs per box

9 pcs per box

Different concrete grinding diamonds have various packaging methods based on quantity. For Lavina diamond tooling, we offer three different packaging quantities: 6 pieces per box, 9 pieces per box, and 12 pieces per box. Among these, the most popular option is 6 pieces per box.

To make the tools easily identifiable from outside the box, we affix a label on the surface of the box indicating the product name, diamond grits, and bond types.

| Suitable Grinders | Lavina |

|---|---|

| PCD Combination | PCD Only |

| PCD Sizes | 1/2 PCD |

| PCD Vertical Directions | Round Corner Up |

| Tool Shapes | Trapezoid |

Related products

-

2 Buttons Husqvarna Grinding Segments for Concrete

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Husqvarna, Diteq

- Diamond Segments

- 2 segment buttons;

24x10mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.18kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

Single Zigzag Husqvarna Diamond Grinding Segments for Concrete

- Application

- Surface preparation; Aggregate exposure; Glue & coating removals

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi-lock adapter

- Diamond Segments

- 1 zigzag segment;

36*5*12mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- will update soon

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

2 Bars Segmented HTC Grinding Diamonds for Concrete Floor

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- HTC, Husqvarna(EZ system)

- Diamond Segments

- 2 segment bars(40x12x10mm)

- Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.21kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

2 Hexagons Husqvarna Redi Lock Diamond Segments for Concrete

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi-lock adapter

- Diamond Segments

- 2 hexagonal segments;

33*8/17*12mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.18kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds