125mm Concrete Grinding Wheel with Spiral Segments

September 29, 2024

125mm Z-shape Segmented Hilti Concrete Grinding Disc

September 29, 2024

125mm Zigzag Concrete Diamond Cup Wheel

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Angler grinders

- Diamond Segments

- 6 zigzag segments

- Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.4kg

- MOQ

- 6 pieces

- Lead Time

- 1-2 weeks

Buying Guide for Concrete Grinding Cups

Table of Contents

Product Features

- Aggressive Grinding Capabilities: Zigzag segments, or “step segments,” feature a narrow width and multi-cornered design for exceptionally aggressive material removal.

- Versatile Applications: Excels at removing stubborn concrete floor coatings such as epoxy, paint, glue, and mastic.

- Efficient Surface Preparation: Ensures effective preparation of the underlying surface for subsequent treatments or finishes.

- Traditional Cup Wheel Core: Utilizes a traditional cup wheel core, which concentrates pressure during grinding for more aggressive material removal compared to flat cores.

Description

Zigzag segments, also referred to as “step segments,” are characterized by their narrow width and multi-cornered design, which contribute to their exceptionally aggressive grinding capabilities. This unique configuration allows for effective material removal, making them particularly suitable for use with lower diamond grits. When paired with these grits, zigzag segments excel at removing tough concrete floor coatings such as epoxy, paint, glue, and mastic. Their aggressive cutting action enables them to tackle stubborn materials efficiently, ensuring that the underlying surface is prepared effectively for subsequent treatments or finishes. Whether you’re handling heavy-duty removal tasks or seeking to achieve a clean surface, zigzag segments provide the performance needed to get the job done.

This 125mm concrete diamond cup wheel features 6 zigzag segments designed for optimal performance. To maximize the effectiveness of the zigzag segments, we use a traditional cup wheel core rather than a flat core. This is because the segments on a diamond cup wheel experience higher force compared to those on flat grinding wheels. The cup wheel’s design concentrates pressure during grinding, resulting in more aggressive material removal. In contrast, flat grinding wheels distribute force more evenly across a larger surface area, which leads to less concentrated pressure on individual segments.

Optional bond types

Different hardnesses of bonds are used for grinding different hardnesses of concrete. We mainly provide six bonds on our concrete grinding cup wheels, including one Extremely Soft Bond for extremely hard concrete. They are Very Hard Bond, Hard Bond, Medium Bond, Soft Bond, and Very Soft Bond.

There are 2 different code systems to be used for recognizing the tools. To indicate the bond type of the grinding segments, use Bond Codes. To indicate the hardness of the concrete floor, use the Floor Codes. You can use either of them, just make sure you understand.

Concrete hardness and corresponding diamond bonds

| Concrete Hardness | Extremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| MOH'S | 7-9 | 5-7 | 4-5 | 3-4 | 2-3 | 1-2 |

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Bond Type | Extremely Soft Bond | Very Soft Bond | Soft Bond | Medium Bond | Hard Bond | Very Hard Bond |

| Bond Codes | XSB | VSB | SB | MB | HB | VHB |

| Floor Codes | XHF | VHF | HF | MF | SF | VSF |

| Color Represented |

The painting color for each bond is for your reference. If you are a concrete contractor and don't have the requirements on the colors, we will paint the tools according to the chart. If you are a reseller, we will confirm with you about the painting color before arranging the production. You can customize the painting colors, and it's totally free. Please check the following picture to know what colors we do.

Optional painting colors

Here we sort a series of our general painting colors for your reference. You can choose the color from the chart or customize other painting colors by providing us with the code of Pantone colors or others

Generally used colors for concrete grinding diamonds

| Red | A001 | A002 | A003 | A004 |

|---|---|---|---|---|

| Orange | B001 | B002 | ||

| Yellow | C001 | |||

| Green | D001 | D002 | D003 | |

| Blue | E001 | E002 | E003 | |

| Brown | F001 | F002 | F003 | |

| Purple | G001 | |||

| Black | H001 (Bright Black) | H002 (Matte Black) | ||

| Grey | J001 | J002(Silver) | ||

| White | K001 |

Packaging methods – concrete diamond cup wheel

Concrete diamond cup wheels are available in four main sizes: 100mm, 125mm, 180mm, and 230mm. Each cup wheel is individually packed in a sturdy hard box, available in white, brown, or green, with protective pearl cotton ensuring safe transport. The hardness of the three different colored boxes is as follows: the white box is normal, the brown box is harder, and the green box is the hardest. You can choose from these three materials based on your preference.

Each box features a label displaying a product image, which clearly indicates the type of cup wheel, its diameter, grit, and bond type. This labeling makes it easy for customers to identify and recognize the concrete grinding cup wheels they need.

White box

Brown box

Green box

| Production Techniques | High-frequency Welded |

|---|---|

| Diameters | 125mm(5") |

| Connection | 22.23mm, 5/8"-11, M14 |

| Optional Grits | 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220# |

| Optional Bonds | Very Hard, Hard, Medium, Soft, Very Soft, Extremely Soft |

Related products

-

2 Arrows Husqvarna Diamond segments for Concrete

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Lavina and other floor grinders with corresponding adapters

- Diamond Segments

- 2 arrow segments;

20x15x10mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.15kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

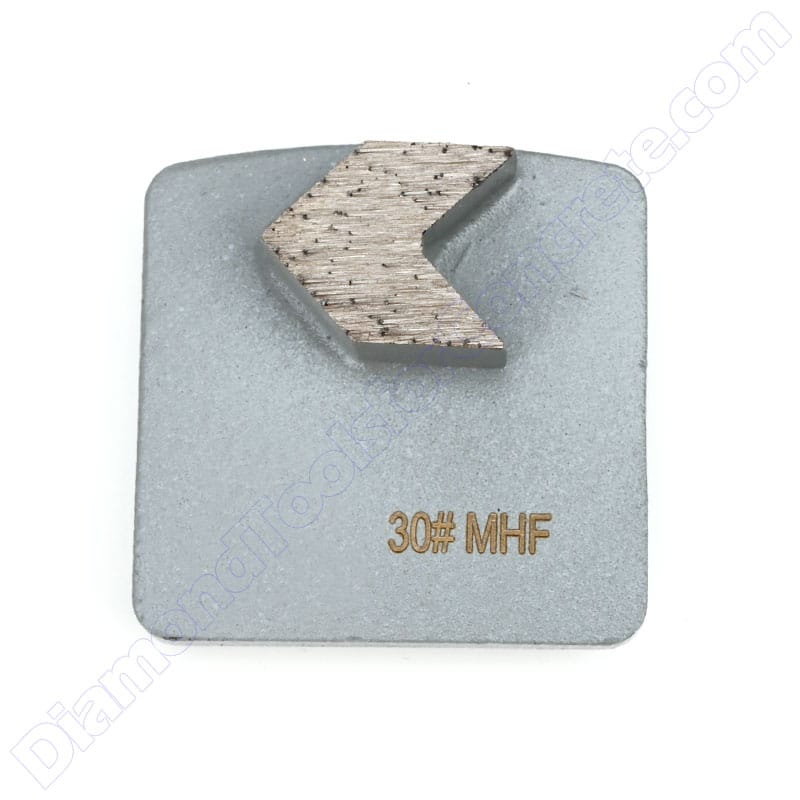

Single Arrow Husqvarna Grinding Diamonds for Concrete

- Application

- Grinding concrete & terrazzo floor

- Suitable Grinders

- Husqvarna, Diteq

- Diamond Segments

- 1 arrow segment;

20x15x10mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.13kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

Single Zigzag Husqvarna Diamond Grinding Segments for Concrete

- Application

- Surface preparation; Aggregate exposure; Glue & coating removals

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi-lock adapter

- Diamond Segments

- 1 zigzag segment;

36*5*12mm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- will update soon

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds

-

2 Zigzags Husqvarna Redi Lock Diamonds for Concrete Grinding

- Application

- Surface preparation; Aggregate exposure; Glue & coating removals

- Suitable Grinders

- Husqvarna, Diteq, and other grinders with redi-lock adapter

- Diamond Segments

- 2 zigzag segments;

XXXmm - Optional

Grits - 6#, 10#, 16#, 20#, 25#, 30#, 60#, 80#, 100#, 120#, 180#, 220#

- Optional

Bonds - very hard

, hard

, medium

, soft

,

very soft , extremely soft - Net Weight

- 0.15kg

- MOQ

- 12 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Grinding Diamonds