230mm Husqvarna Cut-n-Break Twin Blades for Concrete Cutting

June 9, 2024

2 Arrows Husqvarna Diamond segments for Concrete

July 1, 2024

125mm Tuck Point Diamond Blade for Concrete

- Application

- Tuckpointing concrete for various purposes such as cutting channels for installation, creating decorative grooves, concrete crack repair, etc.

- Diameter

- 125mm

- Segment Type

- Normal segments

- Segment Width

- 17mm

- Segment No.

- 12pcs(without 6 teeth on each side)

- Net Weight

- 0.88kg

- MOQ

- 5 pieces

- Lead Time

- 10-20 days

Buying Guide for Tuck Point Blades

Table of Contents

Product Features

- Versatile Applications: Ideal for removing old mortar, cleaning and preparing expansion joints, concrete crack repair, repointing, cutting channels, and creating decorative grooves.

- Customer Endorsement: Positive feedback from users, including a notable customer in the Netherlands for underground pipe installations.

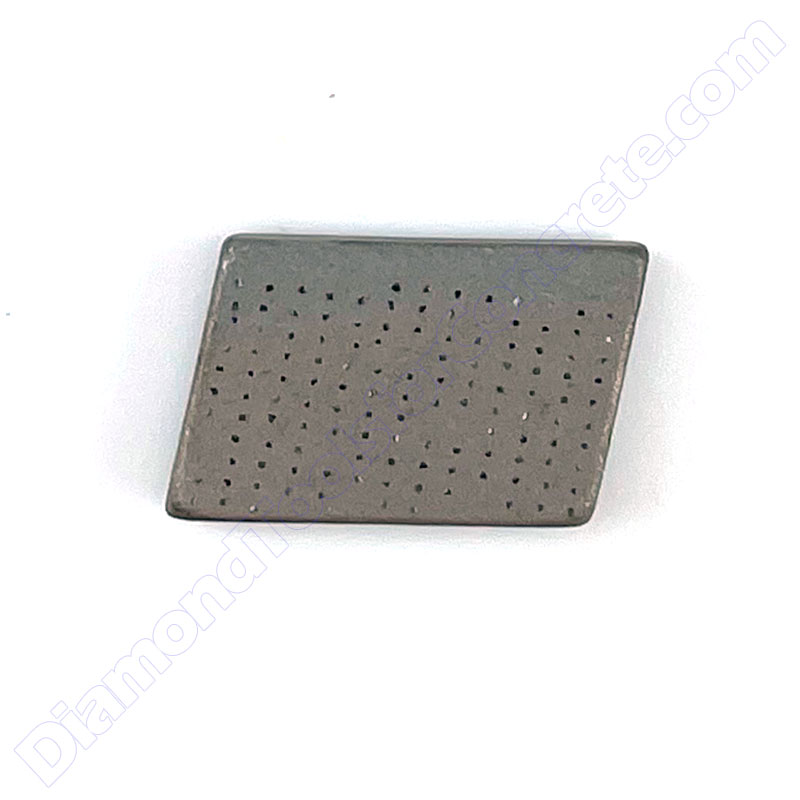

- Segment Configuration: 125mm blade with 24 segments—12 for cutting and 12 side teeth for protection.

- High Welding Strength: Ensures segments stay securely attached during use, maintaining optimal performance.

- Customizable Options: Available in various diameters, segment widths, bond types for different concrete hardness levels, and with or without side teeth for enhanced protection and cleaner cuts.

Description

The tuck point diamond blade is widely used in various applications, such as Removing Old Mortar, Cleaning and Preparing Expansion Joints, Concrete Crack Repair, Repointing Concrete Blocks, Cutting Channels for Installation, and Creating Decorative Grooves. One of our customers in the Netherlands uses our tuck point diamond blade for cutting channels to install underground pipes for ground heating. They have had good experiences with our tools and have given positive feedback.

This 125mm tuck point diamond blade features a total of 24 segments: 12 segments for cutting and 12 side teeth for protection (6 teeth on each side). High welding strength ensures the segments won’t detach during cutting, maintaining optimal performance. Various bonds are available to suit different hardnesses of concrete for tuck pointing.

4 basic info required for tuck point diamond blade

Tuck point diamond blade is a highly customized tool used for tuck-pointing concrete floors. Customization options include the diameter of the blade, the size of the segment, the bond of the segment, and whether or not they have side teeth. When buying tuck point blades, these four points should be considered.

Blade diameter

The diameter of the blade is the basic information required. First, it determines whether it can suit your machine, and second, it determines whether the cutting depth can fit your project. You need to decide the diameter of the tuck point blades based on your cutting machine and the cutting depth you need for your projects.

Segment width

For the segment size, the most important aspect is the width. For a specific cutting project, aside from the cutting depth, the other crucial factor is the width. The width of the segment determines the cutting width. Therefore, the segment width, or cutting width, is a basic specification that we need to know.

Bond type

When tuck-pointing the concrete floor, the process is actually grinding. To maximize the output of the tuck point blade, we need to customize the bond types to target the hardness of the concrete floor. Like our concrete grinding diamonds, we can provide you with various segment bonds for different hardnesses of concrete, including:

- Extremely Soft Bond for extremely hard concrete.

- Very Soft Bond for very hard concrete.

- Soft Bond for hard concrete.

- Medium Bond for medium concrete.

- Hard Bond for soft concrete.

- Very Hard Bond for very soft concrete.

Side teeth

We provide tuck point blades with or without side protective teeth. Usually, the side teeth are not arranged fully under each segment, leaving a gap of one tooth’s distance between two side teeth. Although they require extra cost, there are several advantages of side protective teeth, including:

- Enhanced Protection: The side protective teeth shield the blade’s core and increase its durability, especially when working on hard materials or when there’s a risk of the blade getting pinched.

- Cleaner Cuts: Side protective teeth can help in making cleaner, more precise cuts by stabilizing the blade and reducing wobbling.

| Diameters | 125mm |

|---|---|

| Side Teeth | with Side Teeth |

| Segment Types | Normal |

| Welding Types | Laser |

Related products

-

Arix Diamond Segments for Concrete Cutting Blades

- Application

- For cutting hard materials like concrete, reinforced concrete, hard granite, hard rock, etc.

- Features

- Greatly increases the cutting speed

- Suitable Welding

- Suitable for both laser(suggested) and high-frequency welding

- Segment Size

- Various optional sizes to match different diamond blade sizes

- Net Weight

- Related to the segment size

- MOQ

- 100 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

230mm Husqvarna Cut-n-Break Twin Blades for Concrete Cutting

- Application

- For cutting hard materials like concrete, reinforced concrete, hard granite, hard rock, etc.

- Features

- Deep cutting depth with Husqvarna K760 or K4000 cut-n-break cutters

- Welding Method

- Laser welding (include the central flange)

- Diameter

- 9″(230mm)

- Segment Type

- Wave segments

- Segment Size

- 40×2.8x11mm

- Segment No.

- 15pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade

-

400mm Laser Asphalt Cutting Blade with 4 Drop Segments

- Application

- Cutting asphalt for road and pavement repairs, creating expansion joints, etc.

- Features

- With 4 drop segments

- Welding Method

- Laser welding

- Diameter

- 16″(400mm)

- Segment Type

- Normal segments

- Segment Size

- 40×3.8x12mm

- Segment No.

- 24pcs(4 drop segments)

- Net Weight

- 2.7kg

- MOQ

- 5 pieces

- Lead Time

- 10-20 days

Buying Guide for Asphalt Cutting Blade

-

350mm Vacuum Brazed Concrete and Steel Cutting Discs

- Application

- for cutting concrete and steel

- Diameter

- 350mm(14″)

- Segment Type

- vacuum brazed segments

- Segment Size

- will update soon

- Segment No.

- 26pcs

- Net Weight

- will update soon

- MOQ

- 6 pieces

- Lead Time

- 7-14 days

Buying Guide for Concrete Cutting Blade